High Quality Factory Supply High Precision Die Casting Processing of Zinc Alloy and Magnesium Alloy Components

- Overview

- Recommended Products

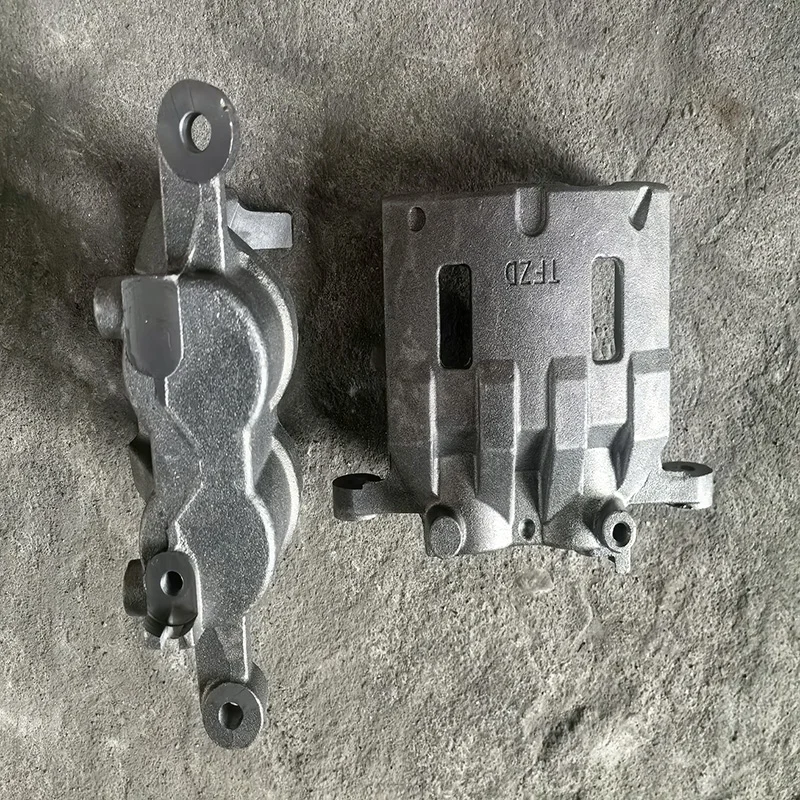

Modern manufacturing increasingly relies on high-precision die casting processes for producing complex, lightweight components with exceptional mechanical properties. Our factory specializes in advanced die casting solutions utilizing both zinc and magnesium alloys, delivering superior quality components for demanding applications across multiple industries.

Advanced Material Properties

Zinc Alloys (primarily ZAMAK series) offer outstanding mechanical strength, hardness, and natural corrosion resistance. These alloys demonstrate excellent fluidity during casting, enabling production of thin-walled components with intricate details. With tensile strengths reaching 47,000 psi and impact strength superior to many engineering plastics, zinc alloys provide exceptional durability in finished components.

Magnesium Alloys represent the lightest structural metals available, with densities approximately 30% lower than aluminum. Despite their lightweight characteristics, magnesium alloys deliver impressive strength-to-weight ratios and excellent electromagnetic shielding properties. Advanced magnesium formulations maintain dimensional stability across temperature variations while offering good machinability for secondary operations.

Precision Manufacturing Capabilities

Our high-pressure die casting processes utilize sophisticated machinery with precise temperature and injection control systems. This technology enables production of components with tight tolerances, typically within ±0.001 inches per inch (±0.025mm per 25mm), while maintaining consistent wall thickness and dimensional stability across production runs.

The die casting process begins with molten metal injection into precision-engineered molds under carefully controlled pressure parameters. This approach ensures complete cavity filling and exceptional surface detail reproduction. Following casting, components often undergo secondary CNC machining operations to achieve critical tolerances and refine functional surfaces.

Enhanced Performance Characteristics

Components produced through our die casting processes demonstrate:

Superior surface finishes requiring minimal post-processing

Excellent dimensional stability across production batches

High corrosion resistance through proper alloy selection and finishing

Enhanced mechanical properties including impact resistance and durability

Complex geometrical capabilities including thin walls and intricate details

Comprehensive Application Versatility

Our zinc and magnesium die casting services support diverse industry requirements:

Zinc Alloy Applications:

Automotive components (latch systems, decorative trim, sensor housings)

Consumer electronics (connectors, housings, mechanical assemblies)

Hardware and fastening systems (locks, handles, mounting brackets)

Medical device components (housing, surgical instruments)

Magnesium Alloy Applications:

Aerospace components (instrument housings, electronic enclosures)

Portable electronics (laptop cases, camera bodies, mobile device frames)

Automotive lightweighting applications (seat frames, steering components)

Industrial equipment (housing for portable tools, measuring instruments)

Quality Assurance and Technical Support

Our manufacturing processes incorporate rigorous quality control measures including:

First-article inspection and statistical process control

Dimensional verification using coordinate measuring machines

Material certification and traceability documentation

Comprehensive testing capabilities including X-ray and porosity analysis

We provide complete technical support from design consultation through production, ensuring optimal manufacturability and performance for every component.

Siz Range |

Not normally over 2.7feet square |

Parts Weight |

0.01pounds to 14 pounds |

Setup Cost |

New die casting tooling is free |

Tolerances |

0.02inch,add0.01inch to 0.015inch across parting line up to part size |

Die Casting Finish |

32~63 RMS |

Minium Draft |

normally 1° |

Billet |

normally 0.04inch |

Normal Minimum Section Thickness |

0.060inch for small parts;

0.090inch for medium parts

|

Ordering Quantity |

For first trial order: not less than 100pcs; Usually 1,000pcs or more. |

Normal Leadtime |

Tooling: 4~12 weeks update part size; Samples: one week if no finish and CNC machining required; Production:2~3weeks |