Spanning 66,000 m² with 40,000 m² of workshops, it has $40M in assets and 330 employees, including 46 technical staff. Annual capacity reaches 100,000 tons

- Overview

- Recommended Products

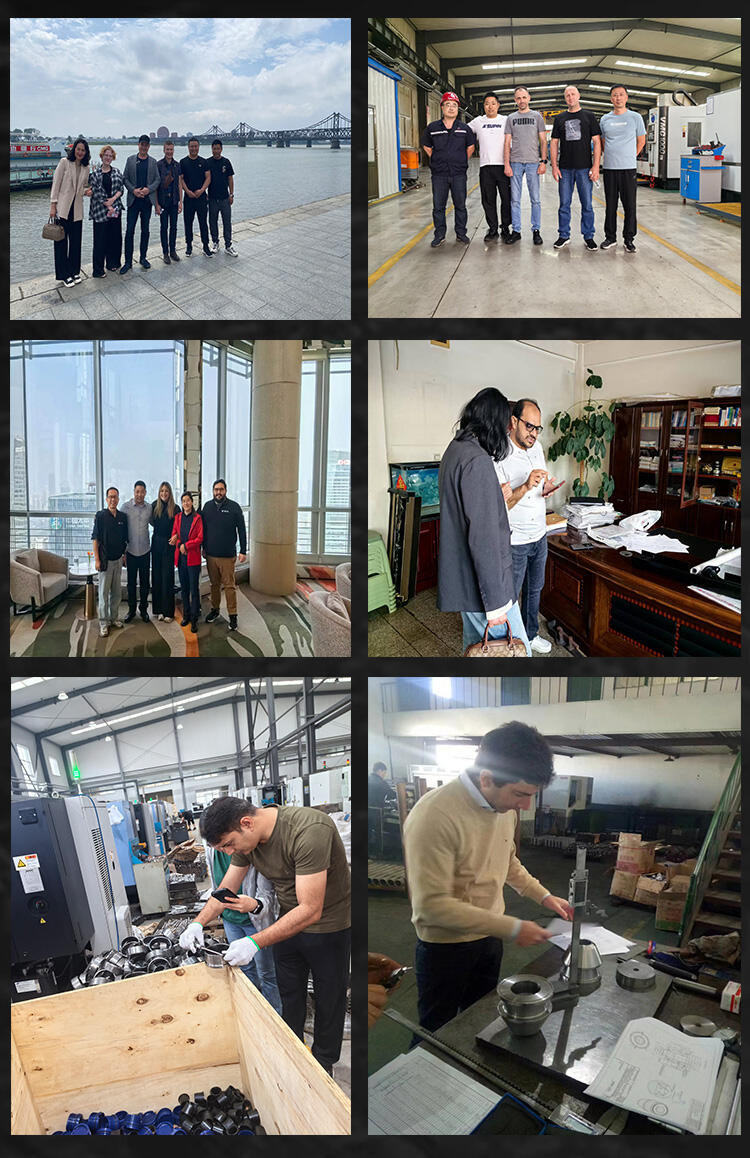

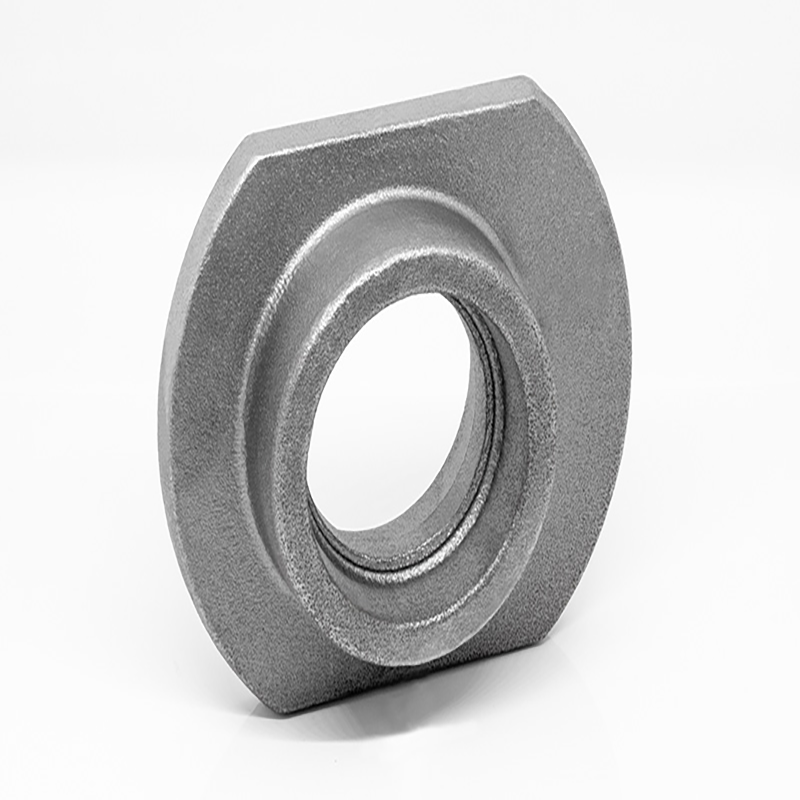

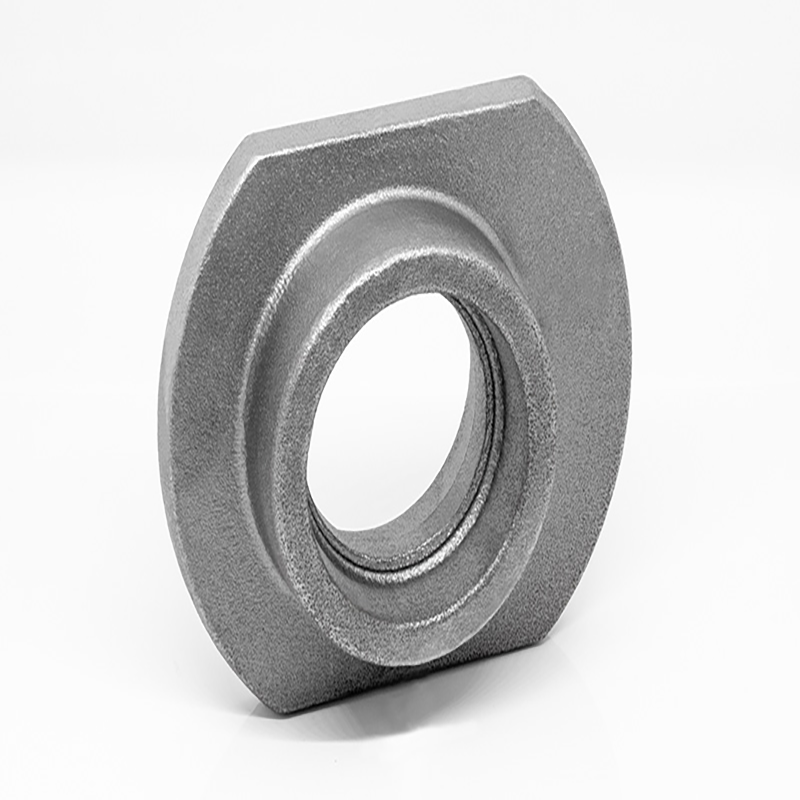

When it comes to creating high-quality steel hot forging parts, look no further than Pengxin Factory Custom Forging Fabrication Services. Our experienced team of professionals is dedicated to providing top-notch forging services tailored to meet your specific needs and requirements

At Pengxin, we specialize in the hot forging process, which involves heating the steel material to a specified temperature and then shaping it into the desired form using precision tools and machinery. This process results in strong and durable parts that are perfect for a wide range of industries and applications

Our factory utilizes state-of-the-art equipment and technology to ensure the highest level of precision and accuracy in every forging project. From start to finish, our skilled technicians carefully monitor the forging process to guarantee that each part meets our strict quality standards

Whether you need custom steel hot forging parts for automotive, aerospace, or industrial applications, Pengxin has the expertise and capabilities to deliver results that exceed your expectations. Our team is committed to providing fast turnaround times and competitive pricing without compromising on quality

When you choose Pengxin Factory Custom Forging Fabrication Services, you can trust that you are working with a trusted and reliable partner. With years of experience in the forging industry, we have built a reputation for excellence and customer satisfaction

Our dedicated customer service team is always available to answer any questions you may have and provide support throughout the entire forging process. We pride ourselves on our attention to detail and commitment to delivering superior products that meet your exact specifications

Pengxin Factory Custom Forging Fabrication Services is your go-to source for high-quality steel hot forging parts. With our expertise, advanced technology, and dedication to customer satisfaction, we are confident that we can meet and exceed your forging needs. Contact us today to learn more about how we can help you bring your forging projects to life

Material |

Aluminum, gray cast iron, ductile iron, stainless steel, copper, brass, galvanized etc |

||||||

Size |

Customized |

||||||

Surface treatment |

Powder coating, electroplating, oxide, anodization |

||||||

Technics |

Laser cut, bend, weld, stamp, casting, forging |

||||||

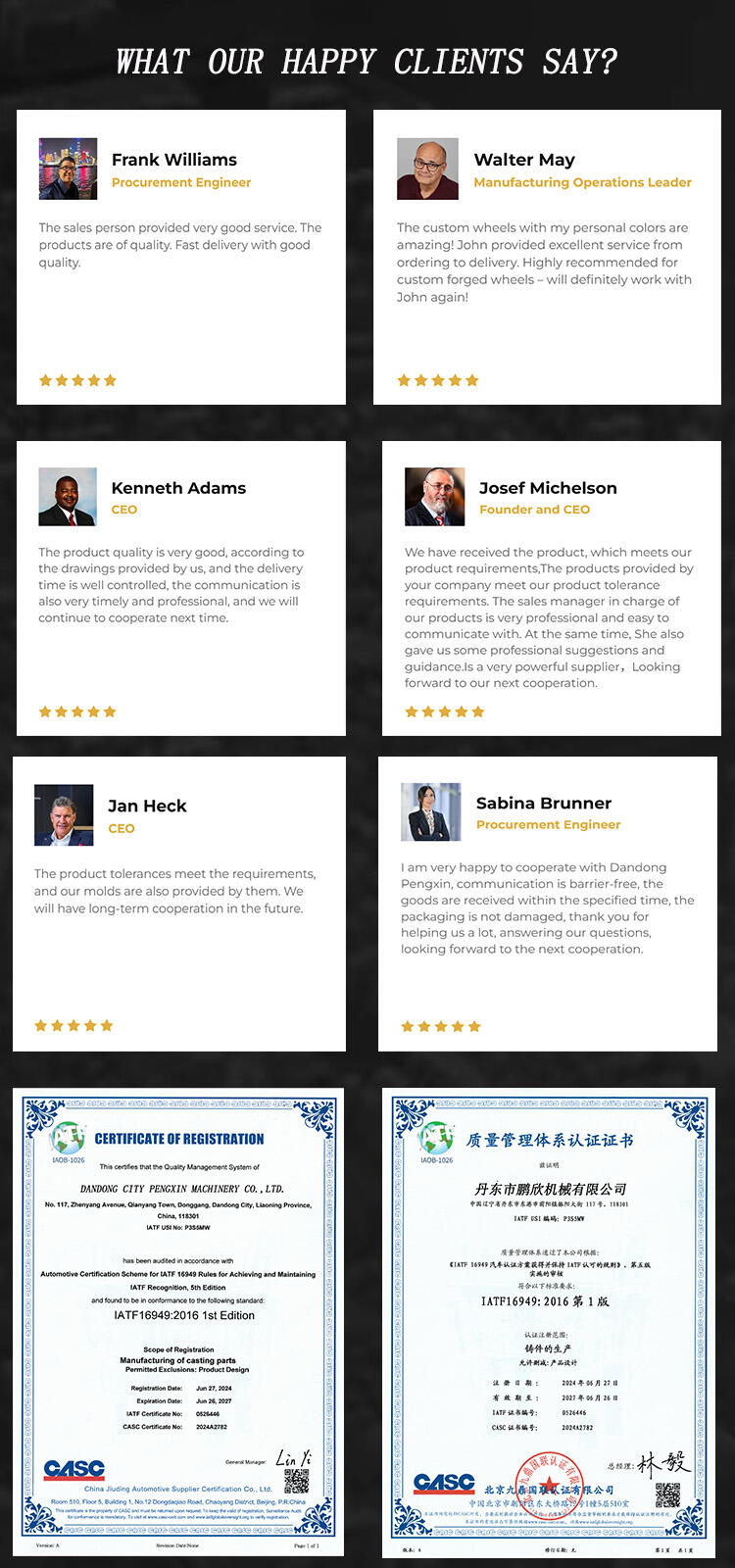

Certification |

ISO9001:2015 |

||||||

OEM |

Accept |

||||||

Drawing Format |

3D/CAD/Dwg/IGS/STEP |

||||||

Color |

Customized |

||||||

Application |

Appliance, Auto, Building, Capital equipment, Energy, Instrumentation, Medical device, Telecommunications |

||||||

Spanning 66,000 m² with 40,000 m² of workshops, it has $40M in assets and 330 employees, including 46 technical staff. Annual capacity reaches 100,000 tons

Pre-sales

On Sale

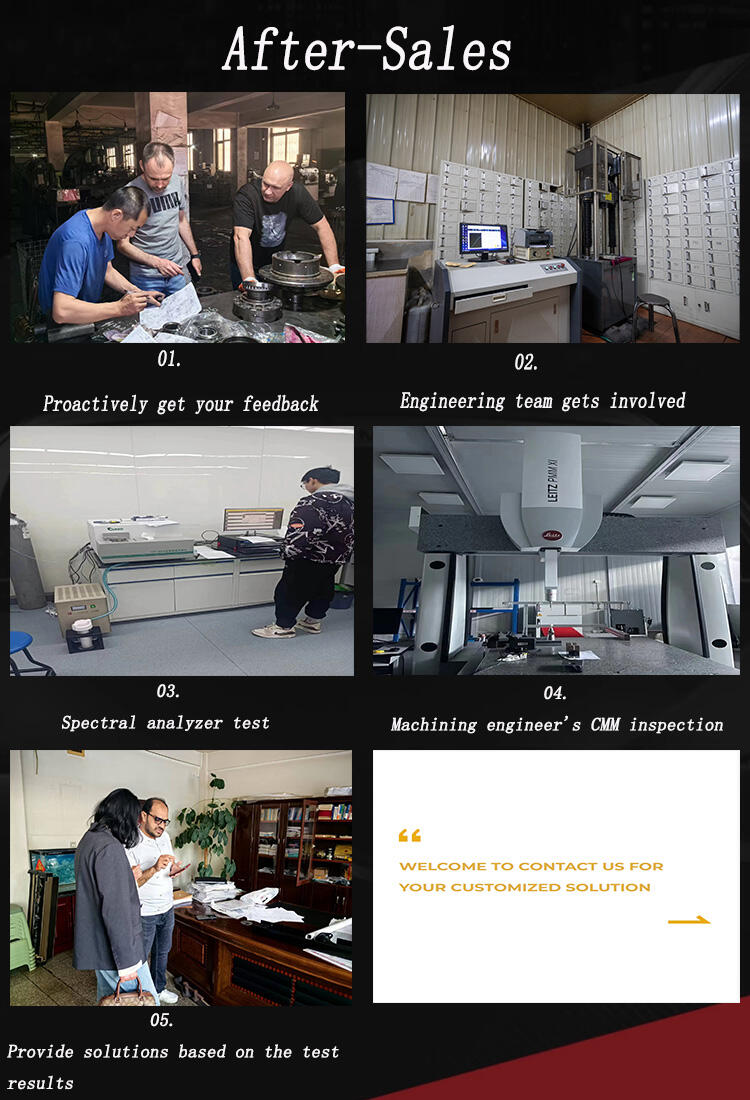

After-Sales

30,000 tons+Annual production capacity for Aluminum

80,000 tons+Annual production capacity for Steel

4000+Mold develop production

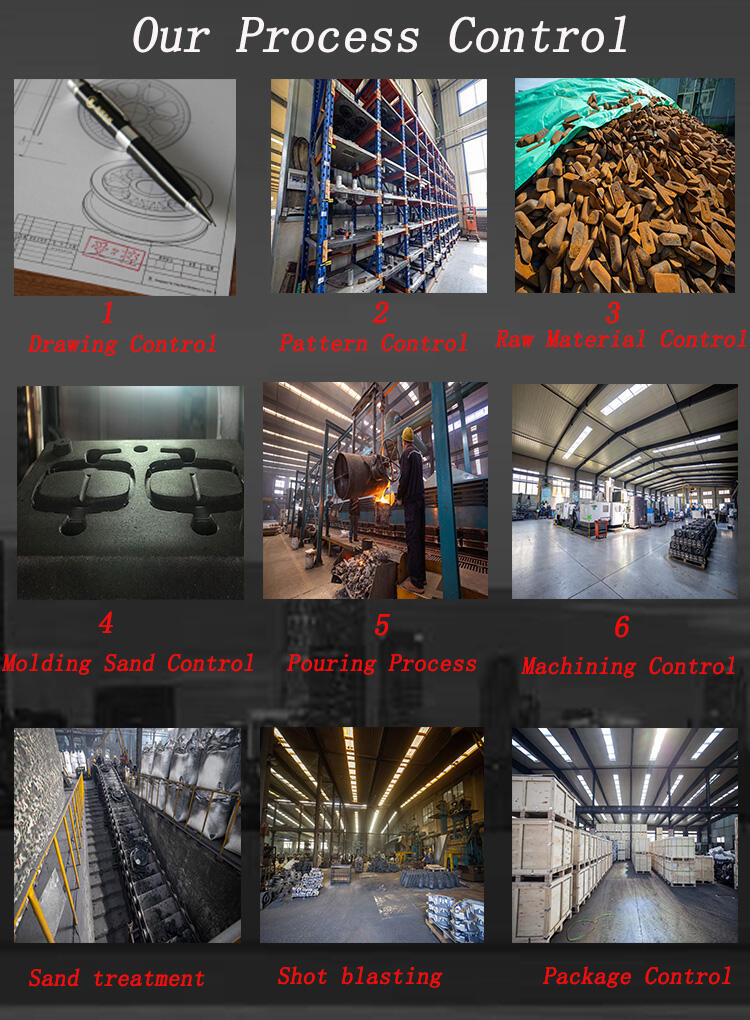

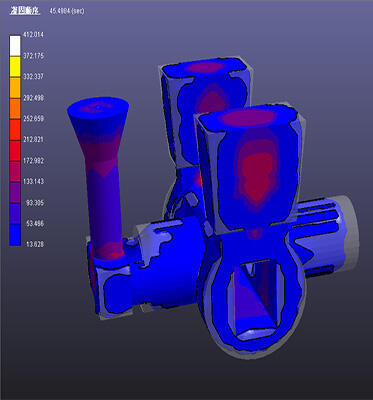

Quality Control

Pattern Control

Raw Material Control

Raw Casting & Machining Control