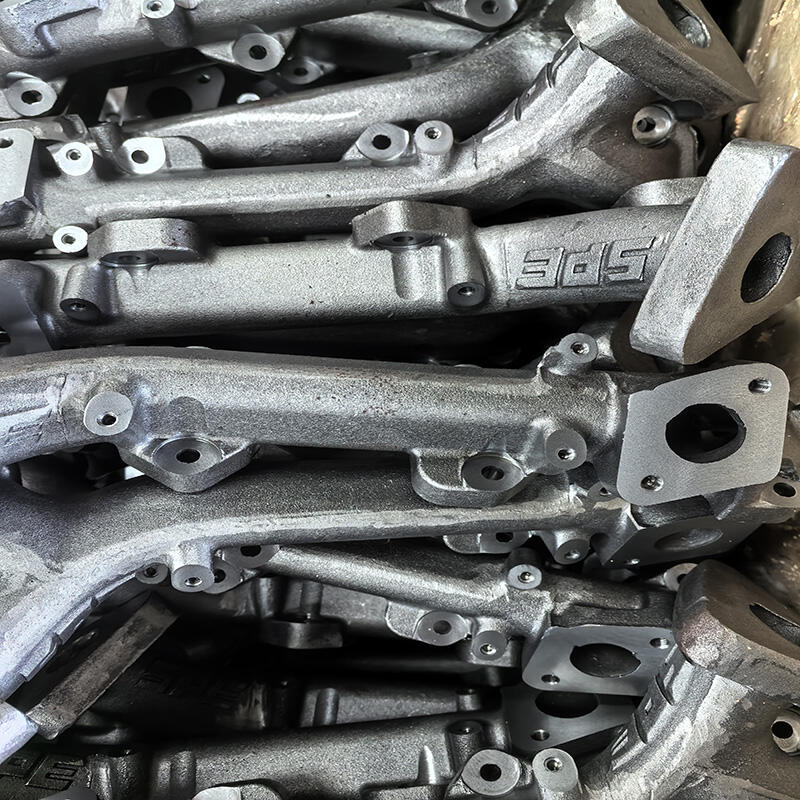

Introducing, the Pengxin DPS Conversion Friendly High Flow 24-Valve and Common Rail Exhaust Manifold, the ultimate performance upgrade for your vehicle.

Designed for maximum efficiency and power, this exhaust manifold is built to withstand even the most demanding conditions. Its high flow design allows for improved exhaust gas flow, resulting in increased horsepower and torque. Say goodbye to restrictions and hello to a smoother, more responsive engine.

The Pengxin DPS Conversion Friendly Exhaust Manifold is specially engineered to be conversion friendly, meaning it can easily adapt to different setups and configurations. Whether you have a 24-valve or Common Rail engine, this manifold will fit seamlessly and enhance your vehicle's performance.

One of the standout features of this exhaust manifold is its durability. Made from high-quality materials, it is built to last and withstand the rigors of daily driving or intense racing. You can trust that this manifold will hold up under pressure and deliver consistent results.

Installation is a breeze with the Pengxin DPS Conversion Friendly Exhaust Manifold. Designed for a perfect fit, it is easy to install and requires minimal modification. With comprehensive instructions included, you can have it up and running in no time, without the need for professional help.

Not only does this exhaust manifold improve performance, but it also enhances fuel efficiency. By optimizing exhaust flow, it helps your engine run more efficiently, saving you money on fuel costs in the long run. You'll notice a difference in both power and economy when you upgrade to this high flow manifold.

Upgrade your vehicle's exhaust system with the Pengxin DPS Conversion Friendly High Flow 24-Valve and Common Rail Exhaust Manifold and experience the difference it can make. Whether you're looking for more power, better efficiency, or improved durability, this manifold has you covered. Invest in your vehicle's performance and upgrade to Pengxin today

Why are we called OEM experts in Exhaust Manifolds |

We develop over 100 different types of exhaust manifolds every year |

|

|

|

Dandong Pengxin Production Process for Exhaust Manifold |

Drawing Preparation: The Foundation of Precision,3D Scanning & Drafting: Our professional engineers use advanced scanners to convert samples into 2D/3D drawings - 7–10 days |

|

|

|

Pattern & Sample Development: Where Time Invested Pays Off |

Complexity: Exhaust manifolds often require 3–5 sets of metal patterns (vs. 1 set for simpler castings). Lead Time: 35–40 days for multi-cavity patterns; 25–30 days for simpler designs |

|

|

|

Initial Orders & Batch Production: Scaling Responsibly |

Machine Allocation: One manifold order may occupy 2–3 molding machines. Our 16-machine facility prioritizes urgent orders and collaborates with partner foundries for auxiliary cores |

|

|

|

How Investors Can Mitigate Delays |

Allocate 8–12 weeks for pattern/sample development. Compressing this risks quality failures. First batches take 20–30% longer due to process fine-tuning. Post-approval, lead times stabilize |

|

|

|

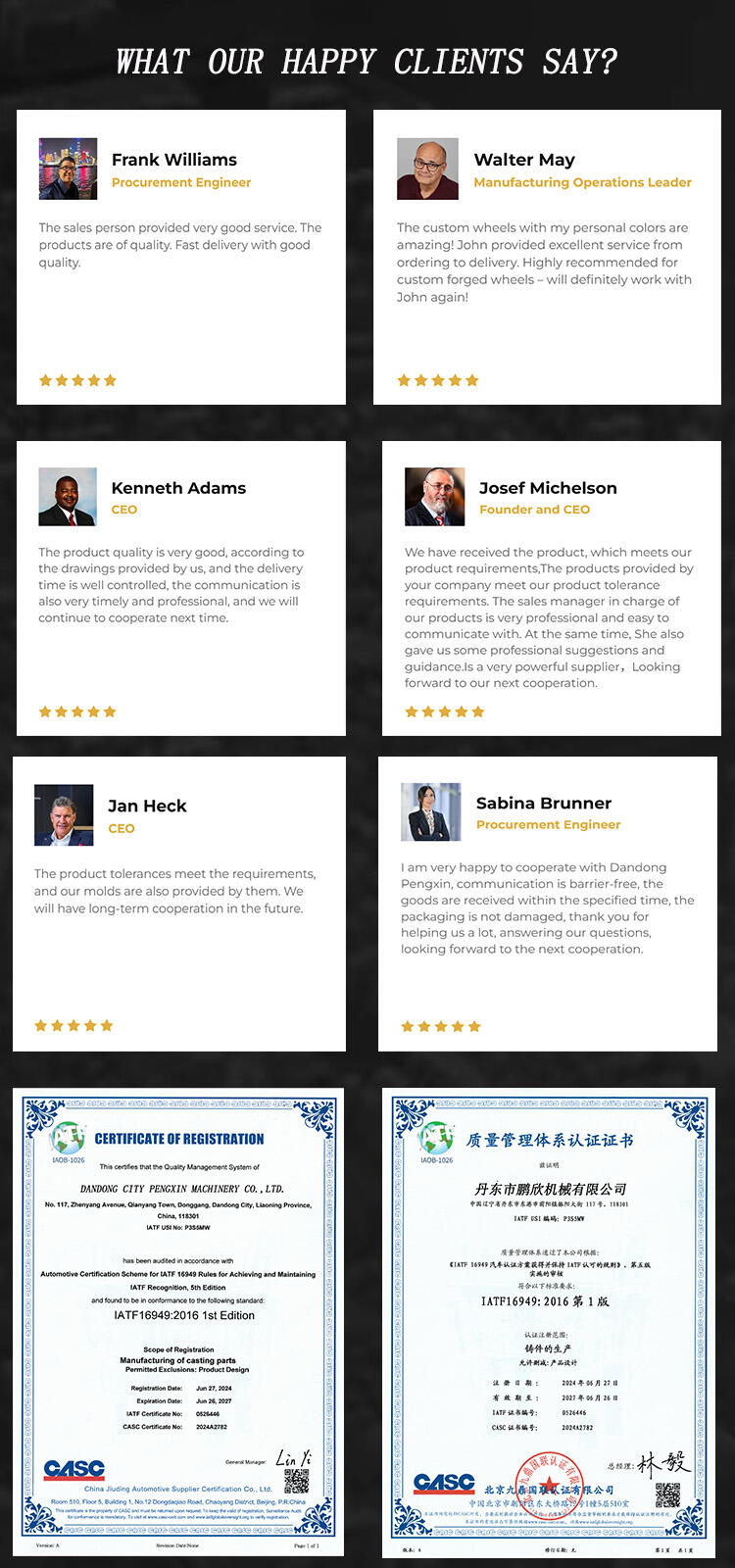

Who We Are

Dandong Pengxin Machinery Co., Ltd., founded in 1958, is a private enterprise specializing in casting, machining, and assembly. Spanning 66,000 m² with 40,000 m² of workshops, it has $40M in assets and 330 employees, including 46 technical staff. Annual capacity reaches 100,000 tons

Equipped with advanced technologies like high-pressure molding and Japanese FBO Ⅲ production lines, it produces up to 30,000 tons/year. Facilities include 12-pulse electronic furnaces, CNC machines, and a quality inspection center with precision instruments

Sell to 80+ countries and regions worldwide, serving large companies such as John Deere, Mercedes-Benz, John Deere, and Weir, Pengxin welcomes partnerships, prioritizing quality, service, and customer satisfaction

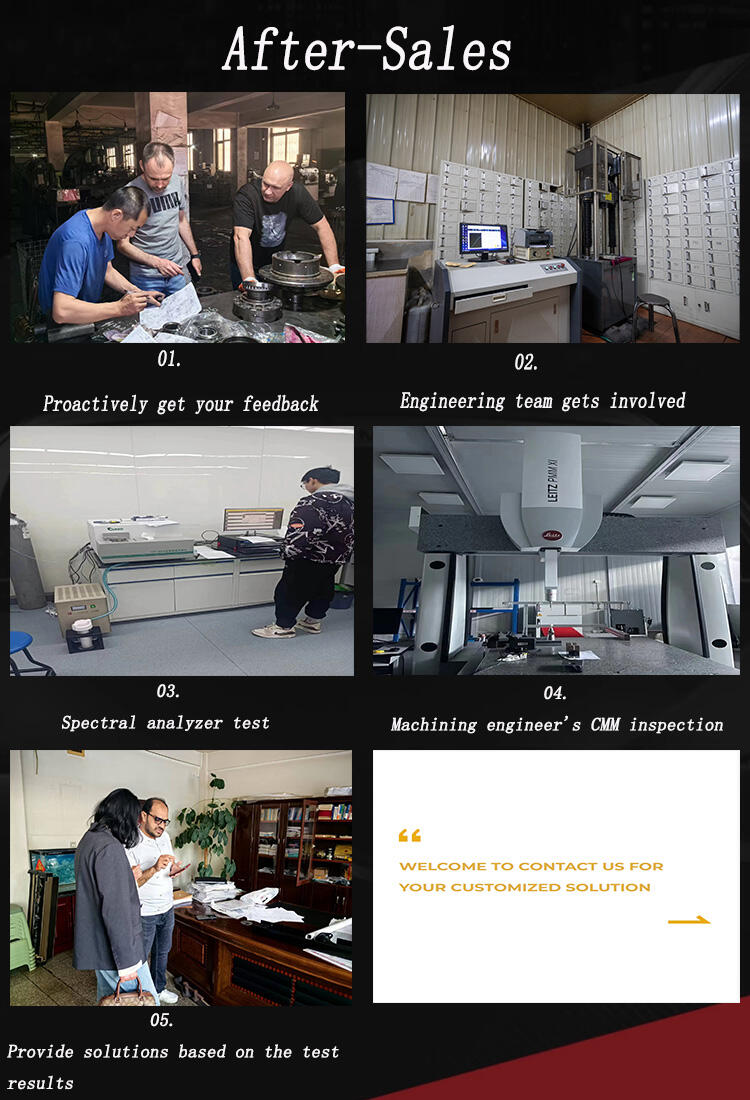

Pre-sales

Get your purchasing needs → Confirm order drawing→ Give customized solution → Offer a quotation → Make the pattern→ Provide samples→ Bulk production after samples approve the test

On Sale

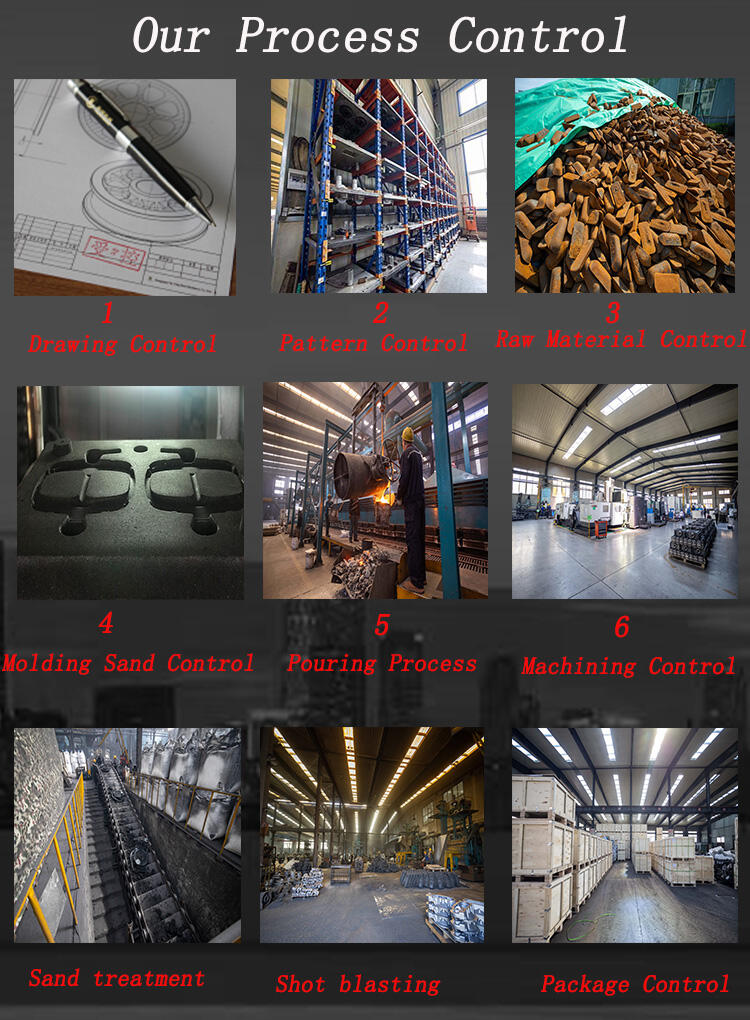

Drawing Control → Pattern Control → Raw Material Control → Molding Sand Control → Pouring Process Control → Raw Casting & Machining Control →Other Requirement Control→ Packing & Delivery Control

After-Sales

Proactively get your feedback→ Engineering team gets involved→Casting engineer conducts metallographic and spectral tests based on the inventory test rods→Machining engineer's CMM inspection is based on the inventory samples→Provide solutions based on the test results→Welcome to contact us for your customized solution

How did Dandong Pengxin Become a Top Manufacturer of Exhaust Manifold

To become a world-leading exhaust manifold producer, Dandong Pengxin Machinery introduced in advanced manufacturing technologies, material innovation, quality control, and supply chain efficiency. Below are the key strategies to achieve this goal

1. Advanced Casting Technologies

(1) High-Precision Casting ProcessesResin-Coated Sand Casting (Main production materials are gray cast iron and ductile iron)

Ensures thin-wall, complex geometries with excellent surface finish (Ra 6.3–12.5 μm).

Ideal for high-performance exhaust manifolds with tight tolerances

(2) Investment Casting - Main production materials are 316 Stainless Steel and Heat-resistant steelUsed for premium turbine housings and racing exhaust components, especially for some freight trucks in the United States

(3) Gravity Casting for Aluminum Manifolds

Lightweight solutions for hybrid/electric vehicle exhaust systems, Gravity casting is the preferred method for mass-producing exhaust manifolds, involving melting metals like cast iron or aluminum and pouring the molten material into preheated steel molds solely by gravitational force. The process naturally fills mold cavities without external pressure, though some advanced variants may apply minimal supplemental pressure (0.2-0.5 bar) for complex geometries. This cost-effective method yields components with uniform 3-6mm wall thicknesses and smooth surfaces, offering superior metallurgical integrity and higher production rates than sand casting, making it ideal for durable exhaust systems requiring consistent quality in high volumes

2. Quality & Certification StandardsISO 9001/TS 16949 (IATF 16949) → Automotive quality compliance

Leak & Pressure Testing → Ensures 100% gas-tight manifolds

Thermal Cycling Tests → Simulates 10+ years of thermal fatigue

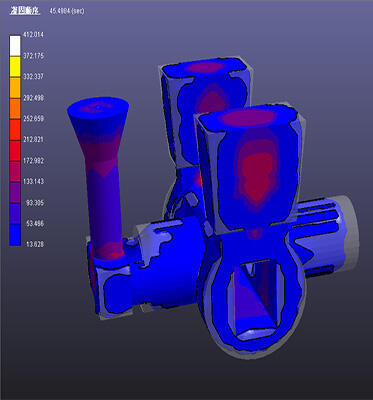

3D Scanning & CMM Inspection → Validates dimensional accuracy - ±0.1mm

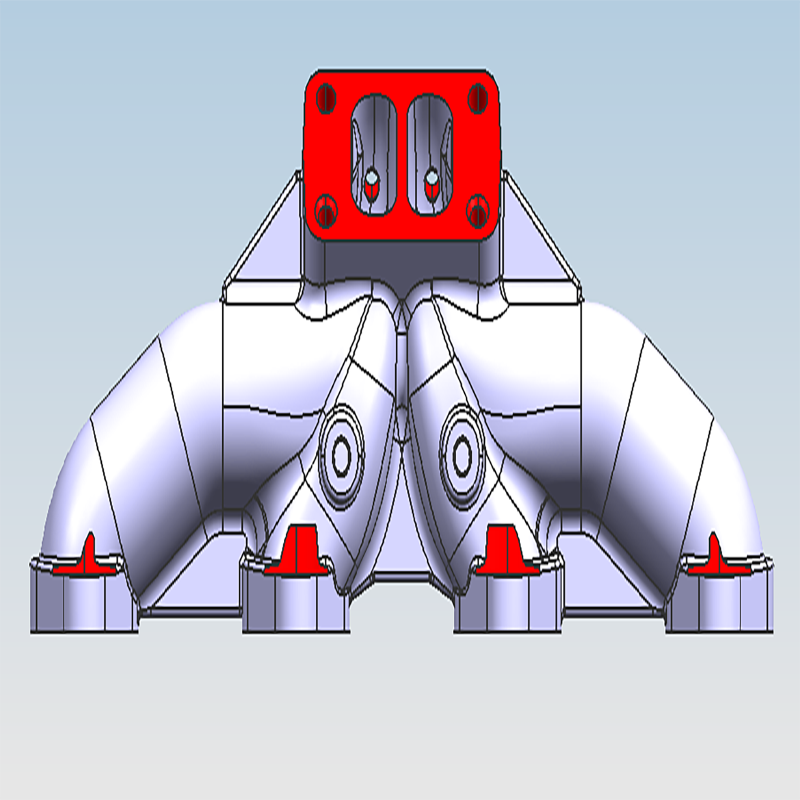

Process designs derive from engineering drawings

Leveraging customer-provided 3D designs, our engineers develop precision mold models and perform comprehensive casting simulation analysis prior to production

3D scanners

Many distributor clients lack 2D drawings - Dandong Pengxin's engineering team expertly converts physical samples into precise manufacturing drawings through professional scanning and reverse-engineering processes

Metal Mold for Exhuast Manifold, Coated sand casting

Industry exclusive: Complete exhaust manifold solutions exceeding 1 meter in length instead of segmented

assembly

Metal Mold for Exhaust Manifold, Sand Casting

90% of our exhaust manifolds are cost-effectively produced using molding machines, keeping both mold and casting expenses low

Exhaust Manifold Core Box

Dandong Pengxin Machinery utilizes proprietary core box forming technology to rapidly produce casting shells and conduct pour tests post-mold completion, significantly reducing lead times

Shell Molding Machine

To address production bottlenecks where each manifold occupies 2-3 molding machines, we implement dual solutions: our 16-machine fleet enables flexible scheduling, while partner foundries provide supplemental sand core production capacity for urgent orders, ensuring reliable delivery timelines

Coated sand casting

Dandong Pengxin specializes in high-precision resin-coated sand casting, producing 50,000+ annual metric tons of automotive components. Our automated lines yield CT7-8 grade castings with 3-6mm walls and Ra 12-25μm finishes. IATF 16949 certified and ISO9001

Molding Machines

We have four iron sand mold casting machines and two FBO III automatic molding lines. Their production capability is 120 sand flasks each hour, 9000 tons each year. Their sand flask size is 605×505×200/200mm

Our Factory strength display

R&D

Our Company Owns A Provincial Level Technology Center, Plus A 15 Person R&D Team, With average 20+ Years Of R&D Experience. We can help customers design for free according to their requirements, or produce according to the drawings or samples

Production Capacity

At Pengxin-Casting, process control begins as early as in the planning and development phase of the products. We support our customers to perform all required tests and inspections in a laboratory. It goes without saying that our plants are certified according to ISO 9001 and IATF16949 in line with a validated quality management. As we strive to accomplish our zero-error policy, you can rely on the following process control measures: Drawing Control → Pattern Control → Raw Material Control → Molding Sand Control → Pouring Process Control → Raw Casting & Machining Control →Other Requirement Control→ Packing & Delivery Control

Pattern Control

We simulate feeding system to check the pattern design from the filling process and material solidification. In this way, we can shorten the mold development cycle, reduce the number of mold trials and improve product quality. The software we use includes

Abaqus,Moldflow and Moldex 3D, simulate feeding system, reduce casting defects and improve efficiency

Raw Material Control

We check the chemistry property as new raw material coming

Machining Control

All dimensions 100% measuring

Raw material spectral analysis and X-ray detection Critical dimensions with CMM measuring

Dandong Pengxin Foundry - Your Trusted Casting Solutions Partner Backed by 67+ years of metallurgical expertise, we deliver precision castings including exhaust manifolds and turbo housings through advanced resin-coated sand and gravity casting technologies. Our 50,000-ton capacity facility features automated molding machines, robotic shell production, and spectral analysis for quality assurance, serving global automotive and industrial clients with IATF 16949-certified manufacturing. Specializing in thin-wall (3-6mm) castings with Ra12-25μm finishes, our engineering team develops optimized solutions from prototype to mass production, supported by in-house mold design and rapid sample development within 15 days