- Overview

- Recommended Products

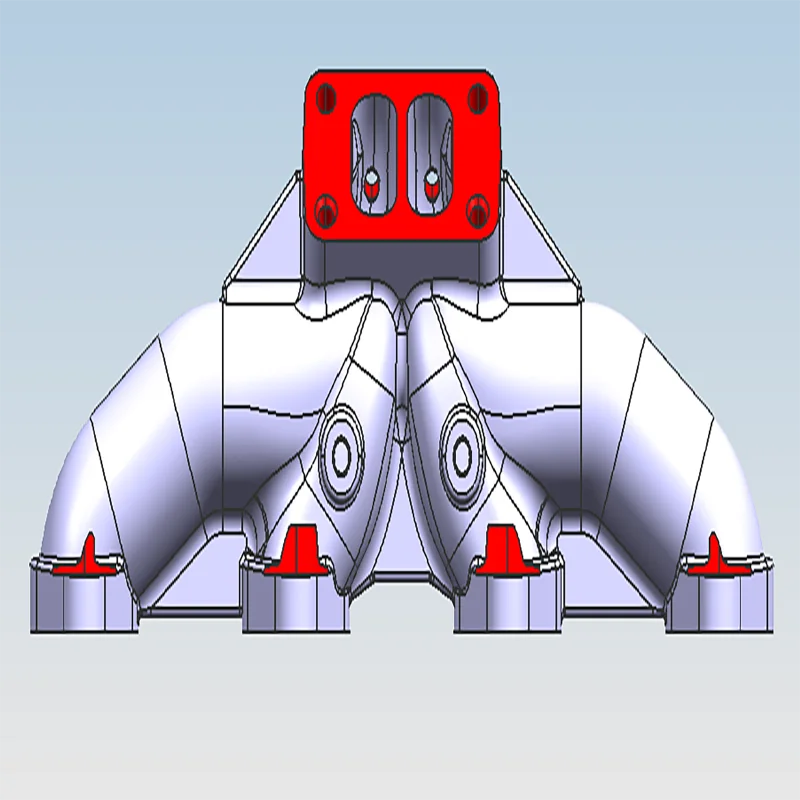

For automotive enthusiasts and performance specialists seeking optimal exhaust flow and durability, the exhaust manifold remains a critical component in engine efficiency. Our New 2.25 Inch Outlet Exhaust Manifolds with Natural Cast Finish represent precision engineering that combines functional performance with manufacturing excellence. These manifolds deliver improved exhaust scavenging while maintaining the structural integrity required for demanding applications.

Premium Material Construction

We manufacture our exhaust manifolds using high-silicon molybdenum ductile iron (SiMo 4.5/5.1), specifically engineered for thermal management in exhaust applications. This specialized material provides:

Exceptional thermal stability maintaining structural integrity up to 850°C

Superior thermal fatigue resistance withstanding repeated heating/cooling cycles

High oxidation resistance in direct exhaust gas environments

Minimum tensile strength of 250 MPa at elevated operating temperatures

Natural corrosion resistance requiring minimal surface treatment

The material's unique composition, featuring 4-5% silicon and 0.5-1.0% molybdenum, ensures consistent performance under thermal cycling conditions while preventing scaling and degradation.

Advanced Manufacturing Process

Our production utilizes sophisticated sand casting technology combined with precision engineering:

Casting Technology

Resin sand molding with 3D-printed patterns for precise runner geometries

Controlled pouring temperatures (1400-1450°C) ensuring proper metal fluidity

Computerized solidification monitoring preventing internal defects

Optimized gating systems for uniform filling and minimal turbulence

Surface Finish Process

Natural cast finish preservation through controlled cooling cycles

Minimal surface processing maintaining as-cast surface integrity

Shot blasting for uniform surface texture without material removal

Visual inspection ensuring consistent finish quality

Performance Characteristics

The 2.25-inch outlet manifolds deliver:

Optimized exhaust flow reducing backpressure by 25-35%

Equal-length runner design improving exhaust scavenging efficiency

Maximum continuous operating temperature of 800°C

Compatibility with standard and performance exhaust systems

Direct bolt-on fitment for specified engine applications

Quality Assurance Protocol

Each manifold undergoes comprehensive validation:

Dimensional verification using coordinate measuring machines

Pressure testing ensuring leak-free performance

Magnetic particle inspection for surface defect detection

Thermal cycling testing simulating real-world conditions

Material certification confirming chemical composition

Technical Applications

These manifolds are engineered for:

Performance street applications requiring reliable power gains

OEM replacement applications where durability is paramount

Mild performance upgrades maintaining factory-like appearance

Restoration projects requiring original-equipment style components

Commercial vehicle applications demanding long service life

The natural cast finish provides not only an authentic appearance but also maintains the material's inherent corrosion resistance without compromising surface integrity through excessive machining or processing. Our engineering team ensures each manifold meets strict performance criteria while delivering the reliability and durability that performance enthusiasts and professional installers demand. By combining advanced foundry technology with precision engineering, we create exhaust manifolds that balance performance requirements with manufacturing excellence, providing optimal value for both everyday drivers and performance enthusiasts.

Why are we called OEM experts in Exhaust Manifolds |

We develop over 100 different types of exhaust manifolds every year |

||||||

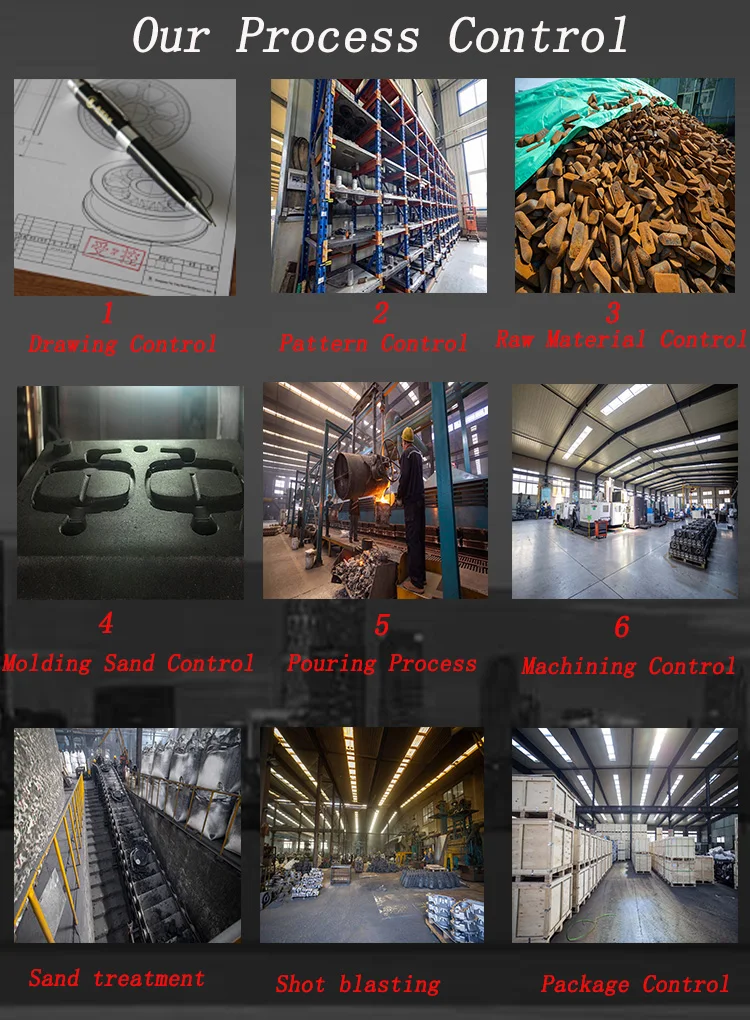

Dandong Pengxin Production Process for Exhaust Manifold |

Drawing Preparation: The Foundation of Precision,3D Scanning & Drafting: Our professional engineers use advanced scanners to convert samples into 2D/3D drawings (7–10 days). |

||||||

Pattern & Sample Development: Where Time Invested Pays Off |

Complexity: Exhaust manifolds often require 3–5 sets of metal patterns (vs. 1 set for simpler castings).Lead Time: 35–40 days for multi-cavity patterns; 25–30 days for simpler designs. |

||||||

Initial Orders & Batch Production: Scaling Responsibly |

Machine Allocation: One manifold order may occupy 2–3 molding machines. Our 16-machine facility prioritizes urgent orders and collaborates with partner foundries for auxiliary cores. |

||||||

How Investors Can Mitigate Delays |

Allocate 8–12 weeks for pattern/sample development. Compressing this risks quality failures. First batches take 20–30% longer due to process fine-tuning. Post-approval, lead times stabilize. |

||||||

Pre-sales

On Sale

After-Sales

results→Welcome to contact us for your customized solution.

How did Dandong Pengxin Become a Top Manufacturer of Exhaust Manifold

Process designs derive from engineering drawings

3D scanners

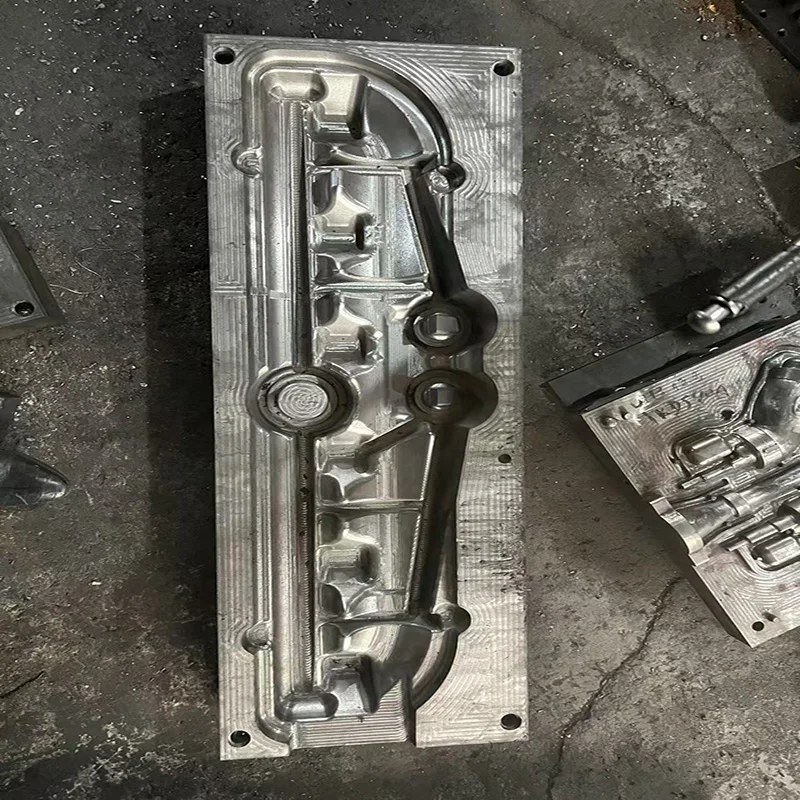

Metal Mold for Exhuast Manifold,Coated sand casting

Metal Mold for Exhaust Manifold,Sand Casting

Exhaust Manifold Core Box

Shell Molding Machine

Coated sand casting

Molding Machines

R&D

Production Capacity

Pattern Control

Abaqus,Moldflow and Moldex 3D, simulate feeding system, reduce casting defects and improve efficiency.

Raw Material Control

Machining Control