ODM Customized Precision Hot Forged Services Forging Parts with Aluminum Alloy Stainless Steel Metal

- Overview

- Recommended Products

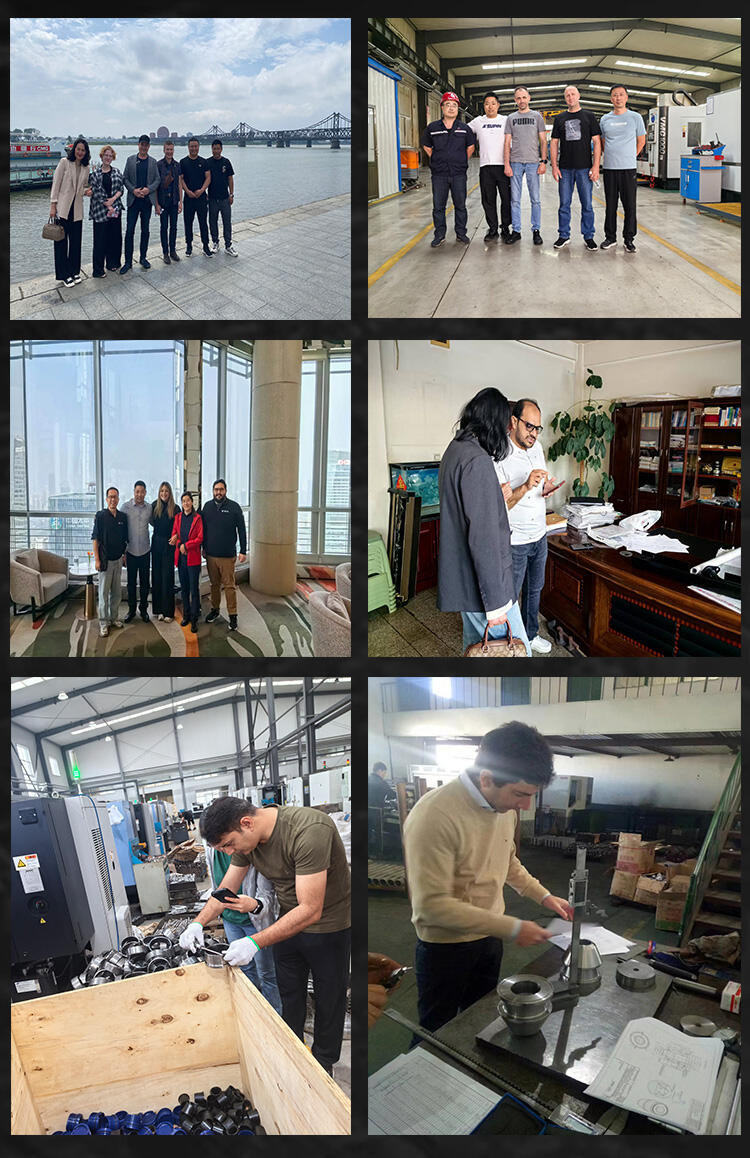

Looking for high-quality hot forged parts made specifically for your needs? Look no further than Pengxin's ODM Customized Precision Hot Forged Services. Our expert team specializes in creating custom forged parts using premium materials such as aluminum alloy and stainless steel.

Our hot forging process involves heating the metal above its recrystallization temperature, making it easier to shape and mold into the desired form. This results in parts that are stronger, more durable, and have excellent mechanical properties. With Pengxin's precision hot forging services, you can trust that your parts will meet the highest standards of quality and performance.

Whether you need custom forged components for industrial, automotive, or aerospace applications, Pengxin has the expertise and capabilities to deliver exactly what you need. Our team of skilled engineers and technicians work closely with you to understand your specifications and requirements, ensuring that the final product meets your exact specifications.

At Pengxin, we are committed to providing top-notch customer service and support throughout the entire manufacturing process. From initial consultation to final delivery, our team will work tirelessly to ensure that your custom forged parts are produced to your exact specifications and delivered on time.

In addition to our hot forging services, Pengxin also offers a wide range of secondary operations such as machining, heat treating, and finishing to further customize your parts. Whether you need a single prototype or a large production run, we have the capabilities to handle your project with precision and efficiency.

With Pengxin's ODM Customized Precision Hot Forged Services, you can trust that your parts will be manufactured with the utmost precision and attention to detail. Our dedication to quality, reliability, and customer satisfaction sets us apart from the competition, making us the preferred choice for all your hot forging needs.

Experience the difference that Pengxin's precision hot forging services can make for your next project. Contact us today to learn more about our capabilities and how we can help you create customized forged parts that meet your exact specifications

Material |

Aluminum, gray cast iron, ductile iron, stainless steel, copper, brass, galvanized etc |

||||||

Size |

Customized |

||||||

Surface treatment |

Powder coating, electroplating, oxide, anodization |

||||||

Technics |

laser cut, bend, weld, stamp, casting, forging |

||||||

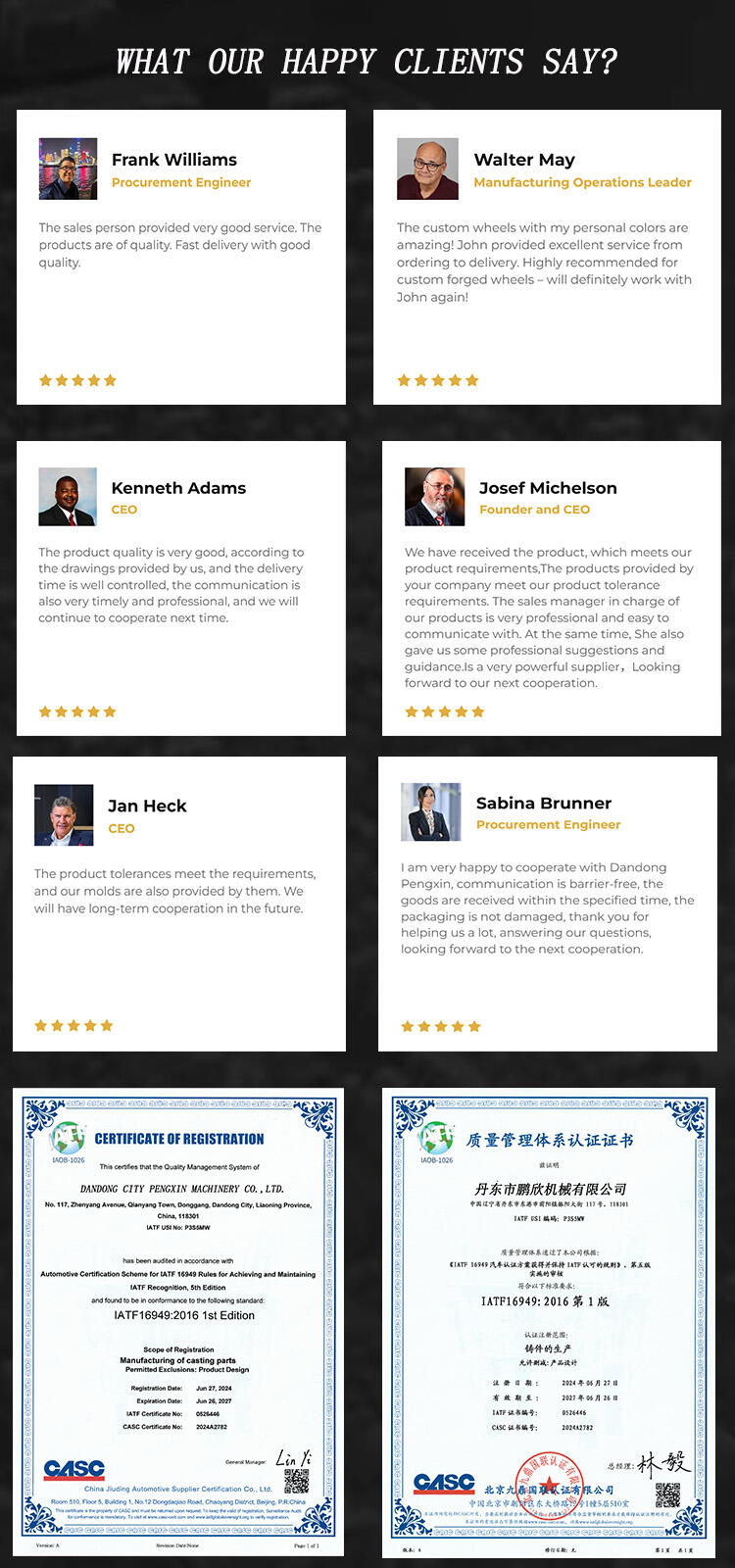

Certification |

ISO9001:2015 |

||||||

OEM |

Accept |

||||||

Drawing Format |

3D/CAD/Dwg/IGS/STEP |

||||||

Color |

Customized |

||||||

Application |

Appliance, Auto, Building, Capital equipment, Energy, Instrumentation, Medical device, Telecommunications |

||||||

Who We Are

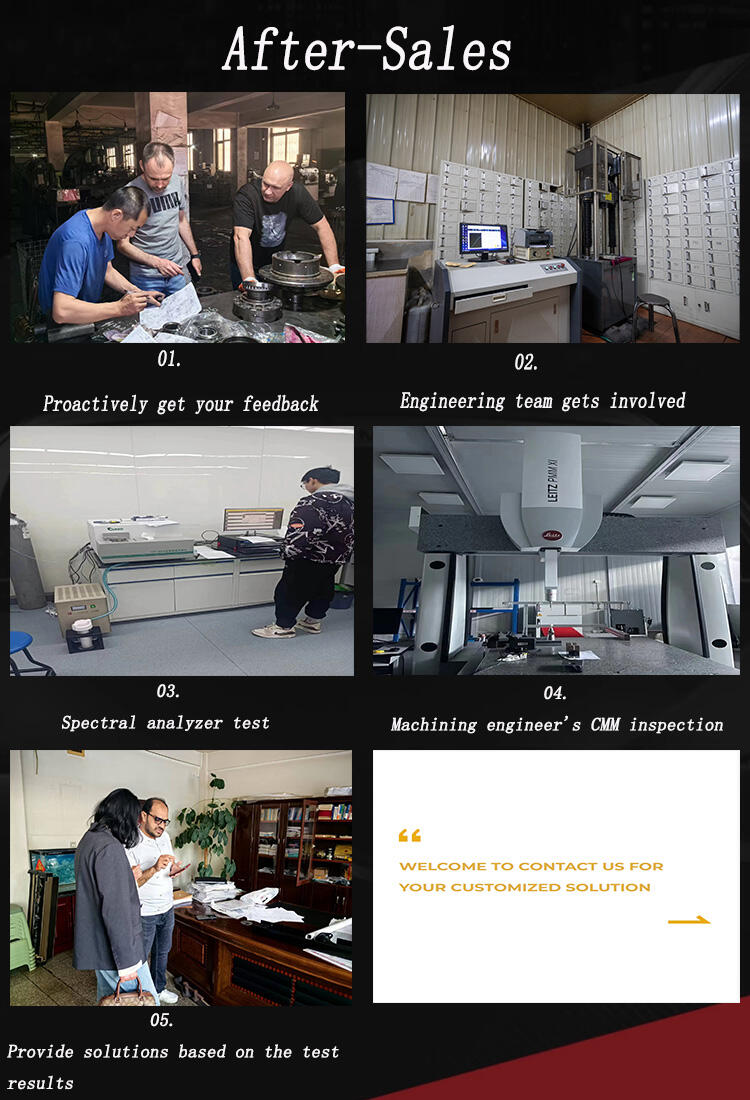

Pre-sales

On Sale

After-Sales

30,000 tons+Annual production capacity for Aluminum

80,000 tons+Annual production capacity for Steel

4000+Mold develop production

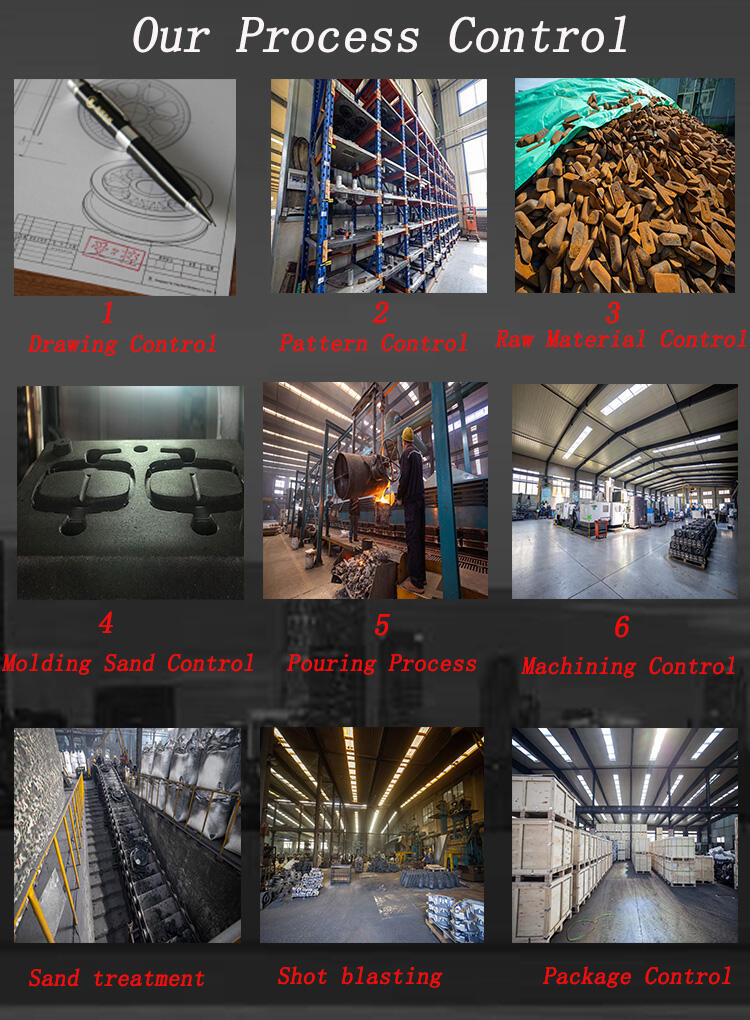

Quality Control

Pattern Control

Raw Material Control

Raw Casting & Machining Control