- Overview

- Recommended Products

In sectors where failure is not an option, the integrity of every component is paramount. As an experienced OEM manufacturer, we specialize in producing custom large closed die steel forgings that set the benchmark for strength, reliability, and performance in the most demanding applications. Our expertise transforms raw steel into critical parts with superior metallurgical properties, unmatched by casting or fabrication.

Advanced Materials and Unmatched Performance

We work with a comprehensive range of alloy steels, carbon steels, and stainless steels, meticulously selected to meet specific operational demands. The closed die forging process fundamentally refines the metal's grain structure, flowing it to follow the part's contours. This results in:

Superior Structural Integrity: A continuous grain flow eliminates porosity and voids, creating parts with exceptional structural consistency.

Enhanced Mechanical Properties: Forged components exhibit higher tensile strength, better impact toughness, and improved fatigue resistance compared to other manufacturing methods.

Greater Reliability: The homogenous microstructure ensures consistent performance and predictable longevity under dynamic and high-stress conditions.

Precision Forging Process and Technical Expertise

Our capability in producing large closed die forgings relies on a controlled, high-pressure process and decades of engineering know-how.

Die Design and Manufacturing: Our engineers design and craft precision-matched die sets from high-grade tool steel to shape the metal under extreme pressure.

Heating and Forging: Steel billets are heated to a precise forging temperature and then shaped using powerful presses or hammers. This multi-step process ensures complete die fill and optimal grain formation.

Heat Treatment: Forgings undergo tailored heat treatment (normalizing, quenching, and tempering) to achieve the required hardness, strength, and microstructural properties.

Machining and Inspection: We offer comprehensive secondary machining on critical surfaces and employ rigorous non-destructive testing (NDT) to guarantee every forging meets stringent quality standards.

Critical Applications Across Heavy Industries

Our custom large steel forgings are engineered for mission-critical roles, including:

Aerospace: Landing gear components, engine mounts, and structural airframe parts.

Oil & Gas: Wellhead equipment, valve bodies, drill string tools, and flange unions.

Power Generation: Turbine shafts, generator rotor hubs, and high-pressure valve bodies.

Heavy Vehicle & Defense: Suspension components, axle beams, and armored vehicle parts.

Leverage our OEM manufacturing expertise for your most challenging component requirements. We deliver forged solutions that provide the foundational strength and reliability your systems depend on.

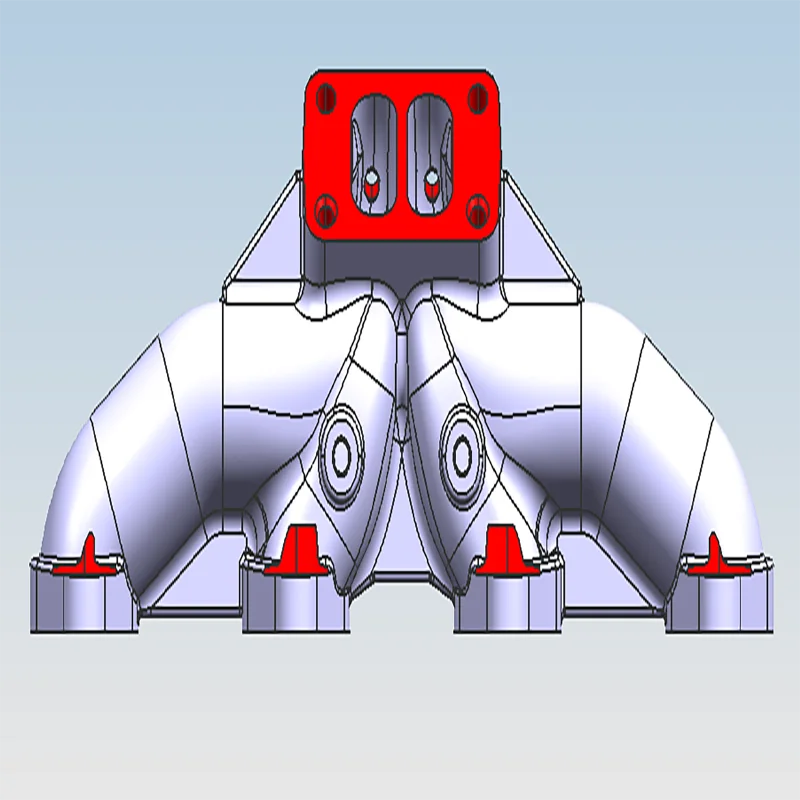

Why are we called OEM experts in Exhaust Manifolds |

We develop over 100 different types of exhaust manifolds every year |

||||||

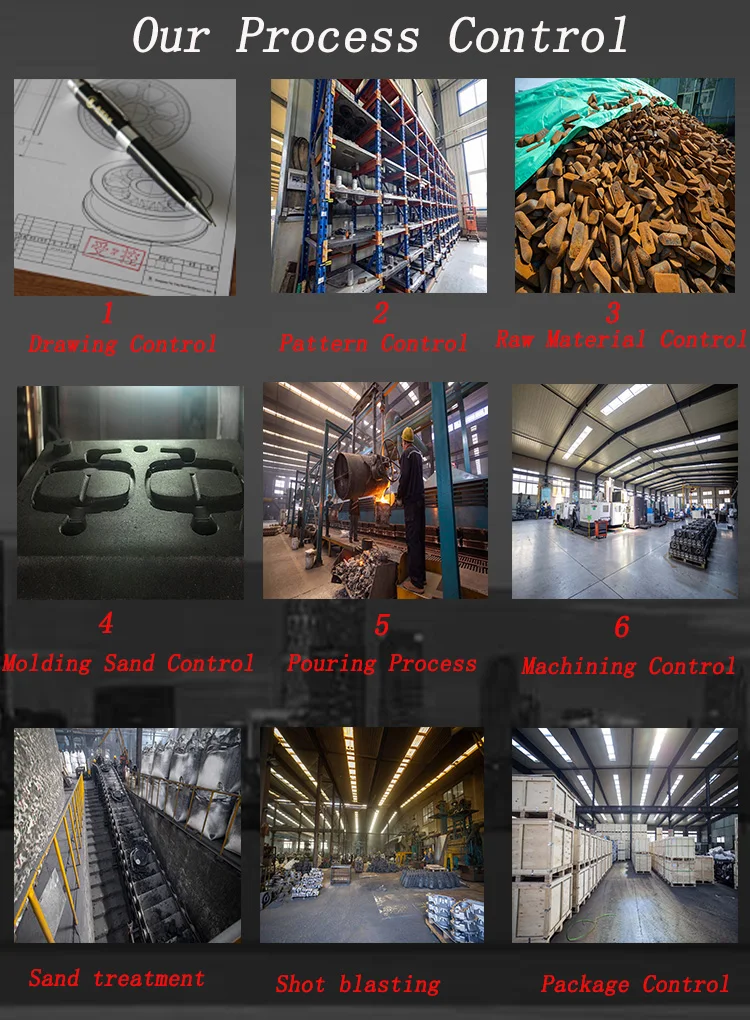

Dandong Pengxin Production Process for Exhaust Manifold |

Drawing Preparation: The Foundation of Precision,3D Scanning & Drafting: Our professional engineers use advanced scanners to convert samples into 2D/3D drawings (7–10 days). |

||||||

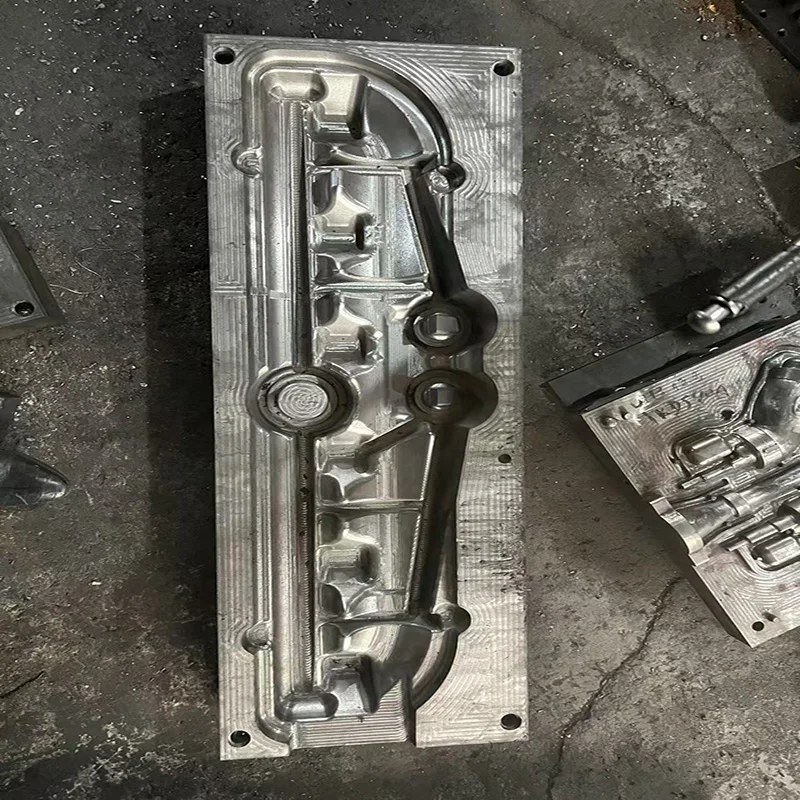

Pattern & Sample Development: Where Time Invested Pays Off |

Complexity: Exhaust manifolds often require 3–5 sets of metal patterns (vs. 1 set for simpler castings).Lead Time: 35–40 days for multi-cavity patterns; 25–30 days for simpler designs. |

||||||

Initial Orders & Batch Production: Scaling Responsibly |

Machine Allocation: One manifold order may occupy 2–3 molding machines. Our 16-machine facility prioritizes urgent orders and collaborates with partner foundries for auxiliary cores. |

||||||

How Investors Can Mitigate Delays |

Allocate 8–12 weeks for pattern/sample development. Compressing this risks quality failures. First batches take 20–30% longer due to process fine-tuning. Post-approval, lead times stabilize. |

||||||

Pre-sales

On Sale

After-Sales

results→Welcome to contact us for your customized solution.

How did Dandong Pengxin Become a Top Manufacturer of Exhaust Manifold

Process designs derive from engineering drawings

3D scanners

Metal Mold for Exhuast Manifold,Coated sand casting

Metal Mold for Exhaust Manifold,Sand Casting

Exhaust Manifold Core Box

Shell Molding Machine

Coated sand casting

Molding Machines

R&D

Production Capacity

Pattern Control

Abaqus,Moldflow and Moldex 3D, simulate feeding system, reduce casting defects and improve efficiency.

Raw Material Control

Machining Control