Spanning 66, 000 m² with 40, 000 m² of workshops, it has $40M in assets and 330 employees, including 46 technical staff. Annual capacity reaches 100, 000 tons.

- Overview

- Recommended Products

Pengxin

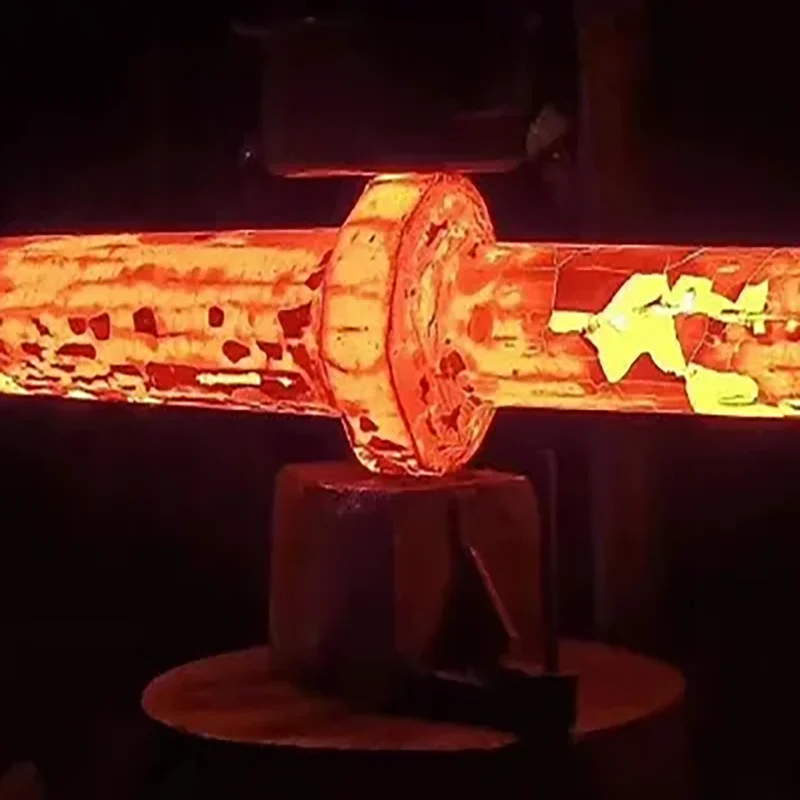

Introducing Pengxin's Customized OEM Precision Cold Forged Brass Parts Cold Forging Machining Service. This top-of-the-line product is designed to meet all of your machining needs with precision and efficiency.

At Pengxin, we understand the importance of high-quality Pengxin parts for your projects. That's why we offer customized OEM precision cold forged brass parts that are made to withstand even the toughest conditions. Our cold forging process ensures that each part is crafted with the utmost accuracy and care, resulting in a superior final product.

Our machining service is second to none, with a team of experts dedicated to providing you with the best possible outcome. Whether you need a single custom part or a large quantity of pieces, Pengxin has you covered. We pride ourselves on our ability to deliver top-notch products that exceed expectations.

The benefits of choosing Pengxin's cold forging machining service are endless. Not only do we offer high precision parts, but we also provide quick and reliable service that you can count on. Our team is committed to ensuring that each part meets your exact specifications, so you can rest assured knowing that you are getting the best possible product.

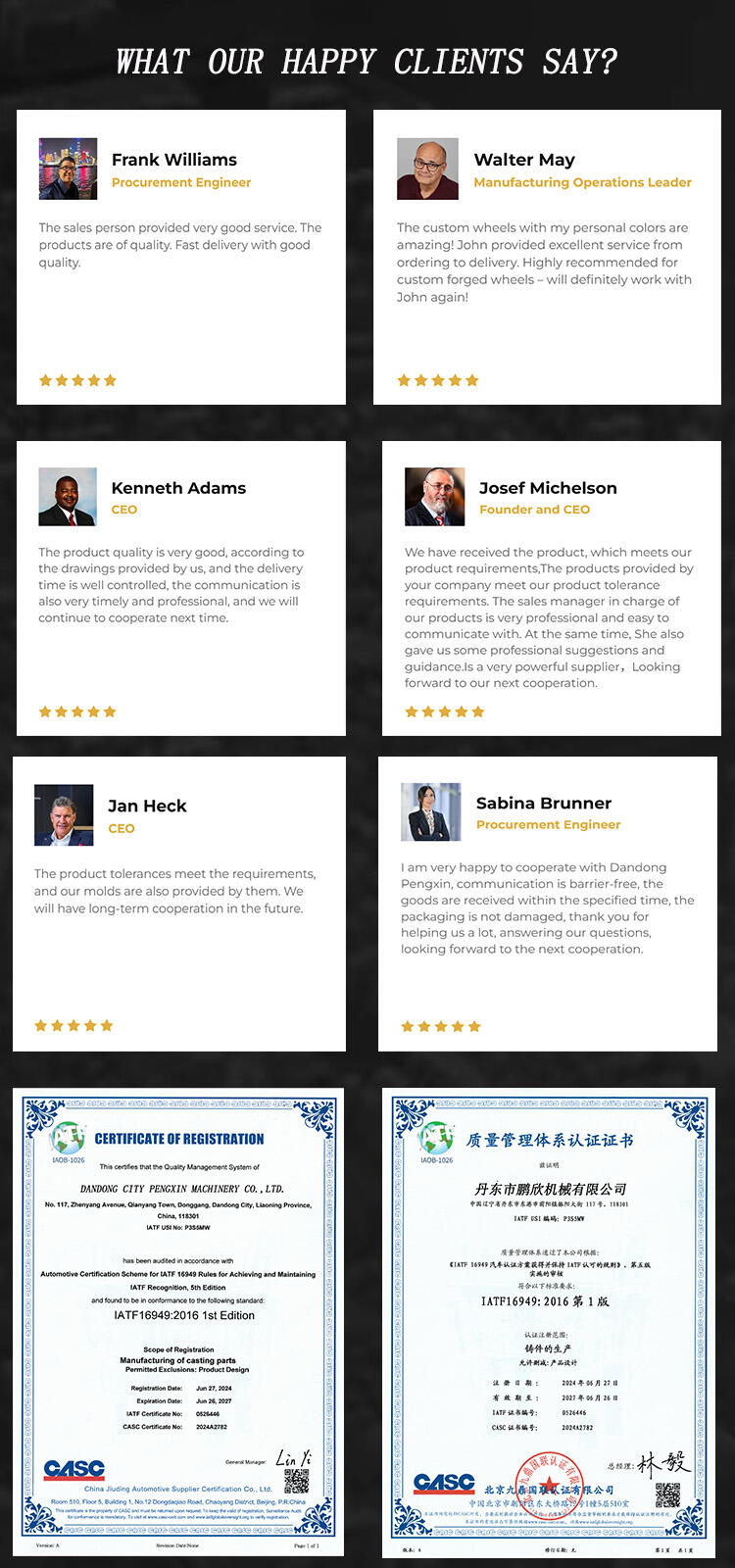

When you choose Pengxin, you are choosing a brand that is synonymous with quality and excellence. Our reputation in the industry speaks for itself, as we have been trusted by countless customers to deliver top-of-the-line products time and time again. With Pengxin, you can trust that you are getting the best of the best.

If you are in need of customized OEM precision cold forged brass parts, look no further than Pengxin's cold forging machining service. With our commitment to excellence and top-notch products, you can trust that you are getting the best possible outcome for your machining needs. Choose Pengxin for all of your cold forging needs, and experience the difference that quality and expertise can make.

Material |

Aluminum, gray cast iron, ductile iron, stainless steel, copper, brass, galvinized etc. |

||||||

Size |

Customized |

||||||

Surface treatment |

Powder coating, electroplating, oxide, anodization |

||||||

Technics |

laser cut, bend, weld, stamp, casting, forging |

||||||

Certification |

ISO9001: 2015 |

||||||

OEM |

Accept |

||||||

Drawing Format |

3D/CAD/Dwg/IGS/STEP |

||||||

Color |

Customized |

||||||

Application |

Appliance, Auto, Building, Capital equipment, Energy, Instrumentation, Medical device, Telecommunications |

||||||

Spanning 66, 000 m² with 40, 000 m² of workshops, it has $40M in assets and 330 employees, including 46 technical staff. Annual capacity reaches 100, 000 tons.

Pre-sales

On Sale

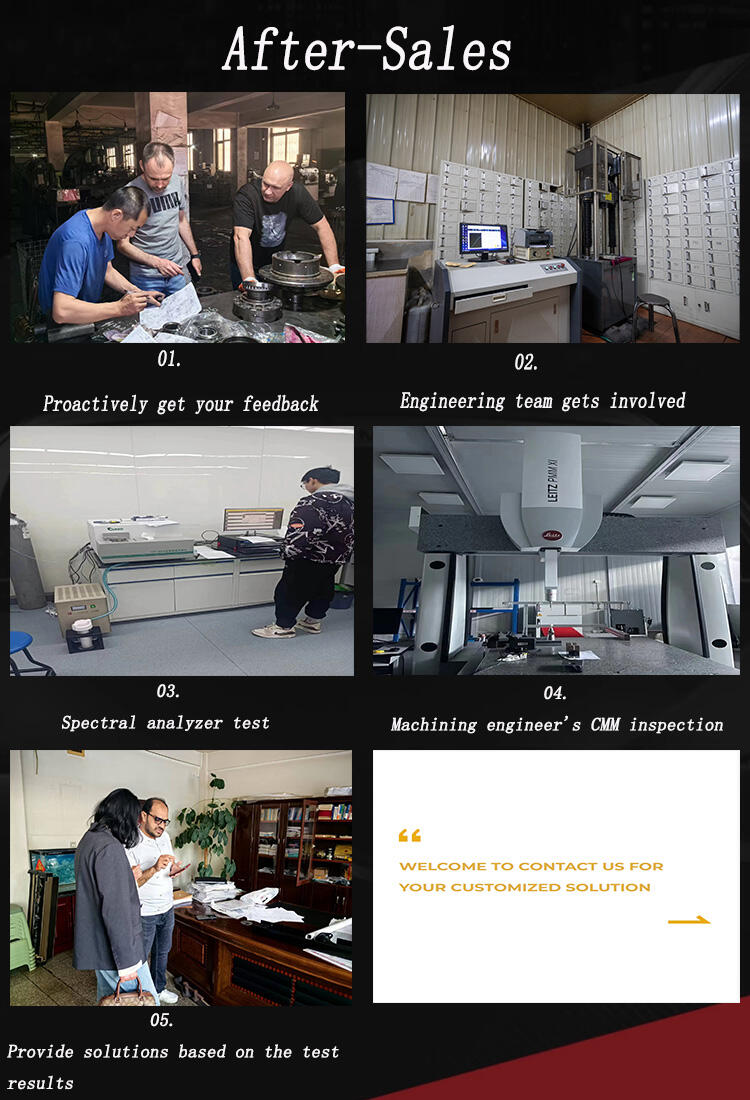

After-Sales

30, 000 tons+Annual production capacity for Aluminum.

80, 000 tons+Annual production capacity for Steel.

4000+Mold develop production.

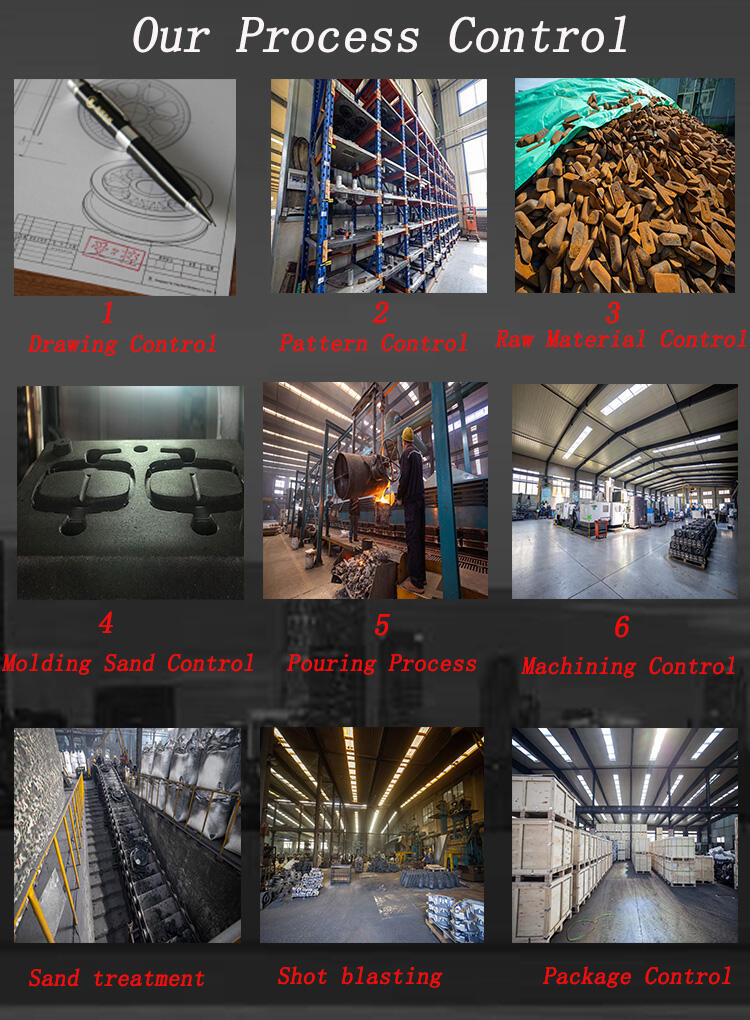

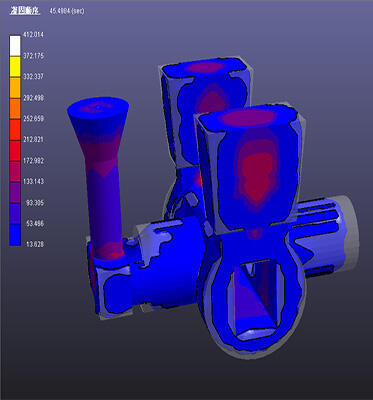

Quality Control

Pattern Control

Raw Material Control

Raw Casting & Machining Control