- Overview

- Recommended Products

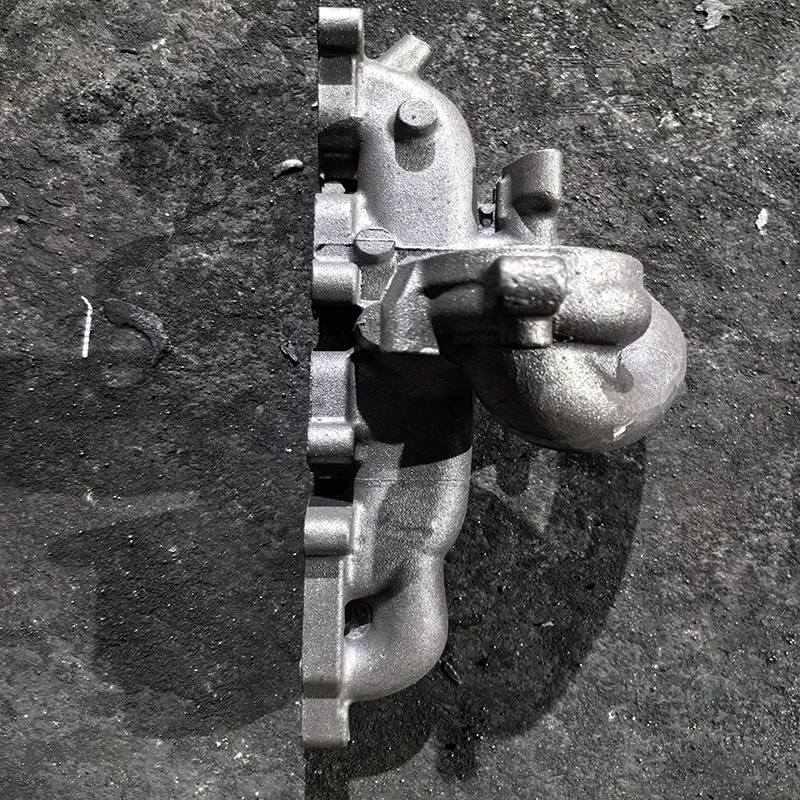

In the high-performance automotive sector, the exhaust manifold serves as the critical junction between engine and turbocharger, directly influencing power output and thermal efficiency. Our Custom New Stainless Steel Iron Investment Casting Parts for Car Turbo Exhaust Manifolds combine advanced metallurgy with precision manufacturing to deliver components that withstand extreme temperatures while optimizing exhaust flow. These custom manifolds provide the perfect solution for performance enthusiasts seeking reliability and power gains in turbocharged applications.

Premium Material Selection

We utilize specialized heat-resistant alloys specifically engineered for exhaust applications:

Austenitic Stainless Steel (304/321/316): Excellent oxidation resistance up to 870°C with good formability

High-Silicon Nodular Iron (SiMo 5.1): Superior thermal fatigue resistance with operating temperatures to 800°C

Heat-Resistant Cast Steel (HK30): Optimal creep resistance under sustained high-temperature operation

Special Alloy Blends: Chromium-nickel-molybdenum combinations for enhanced thermal cycling performance

All materials undergo rigorous validation including:

Spectrochemical analysis ensuring precise alloy composition

High-temperature tensile testing (400-800°C range)

Thermal cycling resistance evaluation (1,000+ cycles)

Microstructure examination for carbide stability and grain structure

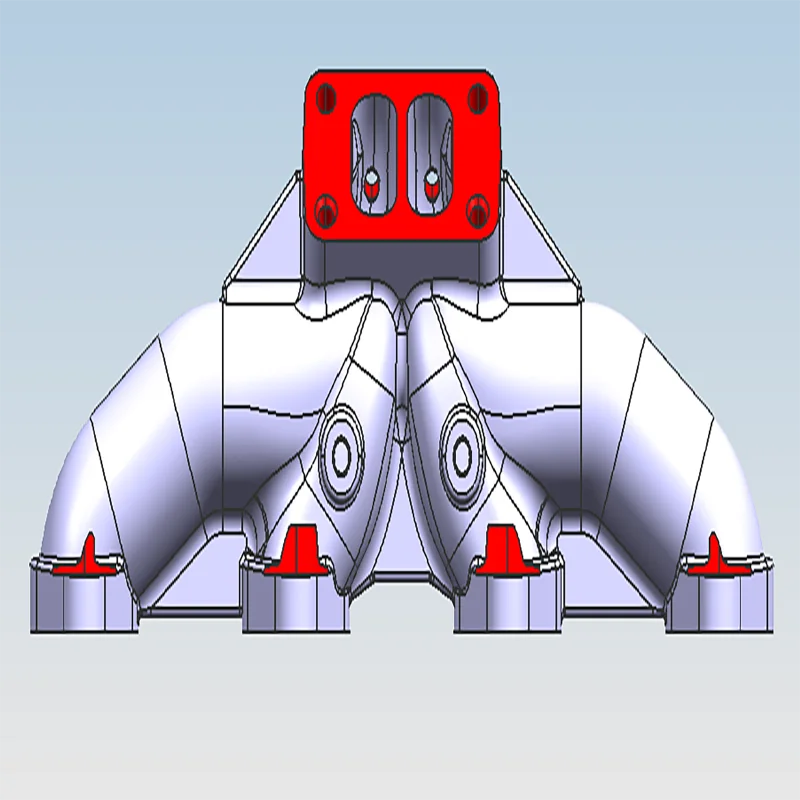

Advanced Investment Casting Process

Our manufacturing employs sophisticated lost-wax investment casting technology:

Pattern and Mold Engineering

3D printed wax patterns for complex runner geometries

Multi-layer ceramic shell building with zircon-based primary coats

Controlled drying environment maintaining 40-60% relative humidity

High-temperature mold firing (1000-1100°C) ensuring shell integrity

Precision Casting Operations

Controlled atmosphere melting preventing surface contamination

Precision pouring temperature control (±15°C)

Computerized solidification simulation for optimal feeding

Automated shell removal and cutting processes

Performance Characteristics

Our turbo exhaust manifolds deliver:

Equal-length runner designs minimizing exhaust interference

Wall thickness optimization (4-6mm) for thermal management

Surface temperatures maintained below 900°C under continuous operation

Thermal expansion compatibility with cylinder head materials

Pressure capability exceeding 3 bar boost pressure

Precision Machining Integration

Critical machining operations include:

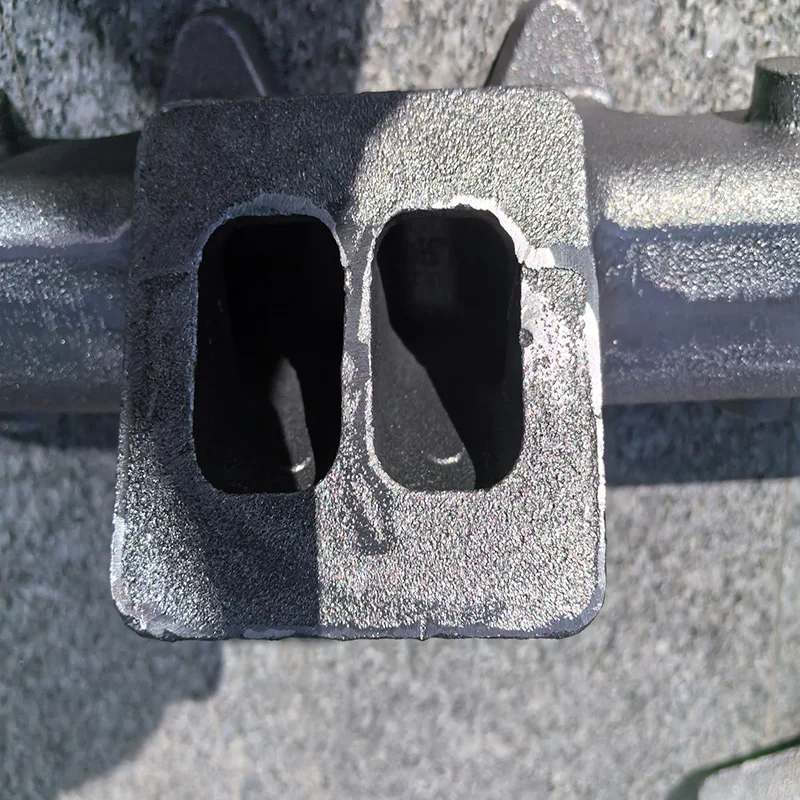

CNC milling of mounting flanges (flatness within 0.1mm)

Precision boring of turbocharger mounting interface

Surface grinding for optimal gasket sealing

Coordinate measuring machine verification

Quality Assurance Protocol

Each manifold undergoes comprehensive validation:

Dimensional inspection using optical scanning technology

Pressure testing to 5 bar for leak prevention

Magnetic particle inspection for surface defects

High-temperature thermal cycling testing

Material certification with full traceability

Technical Applications

Our custom manifolds serve:

Performance automotive turbo applications

Motorsports and racing vehicles

Diesel performance upgrades

Marine turbocharged engines

Industrial turbo machinery

Our engineering team provides complete technical support including:

Computational fluid dynamics analysis for flow optimization

Thermal stress analysis using FEA technology

Custom design for specific turbocharger configurations

Integrated wastegate and external gate options

By combining advanced investment casting with premium heat-resistant materials, we deliver turbo exhaust manifolds that ensure reliable high-performance operation, extended service life, and optimal power delivery. Our custom manufacturing approach guarantees perfect fitment and performance for both professional racing applications and street performance upgrades.

Why are we called OEM experts in Exhaust Manifolds |

We develop over 100 different types of exhaust manifolds every year |

||||||

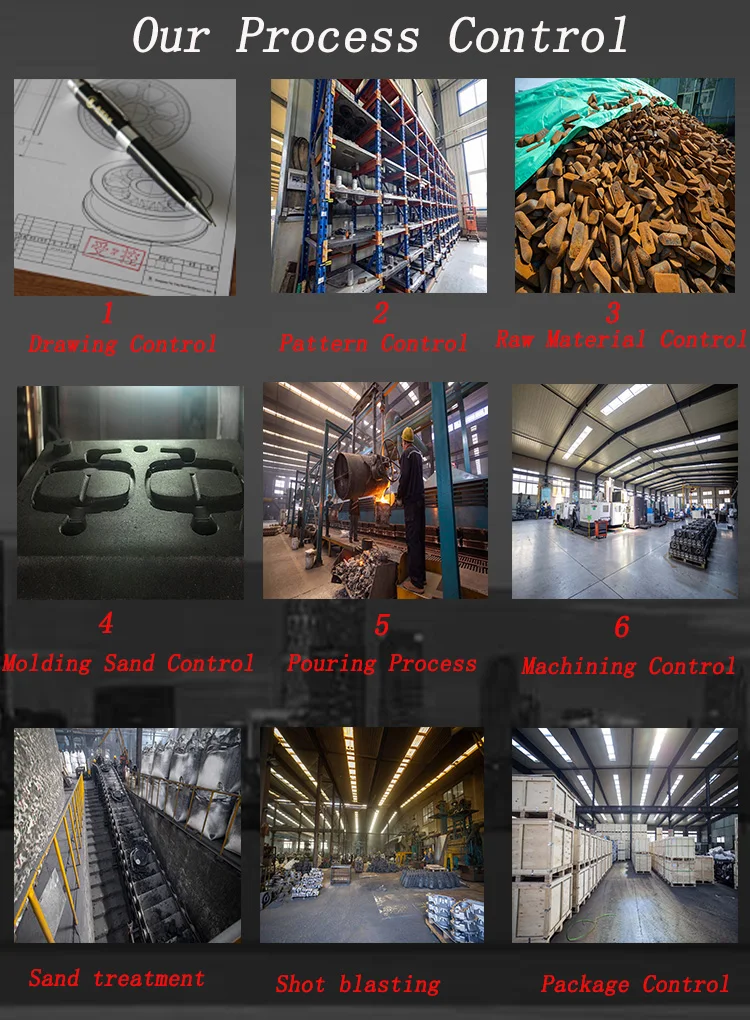

Dandong Pengxin Production Process for Exhaust Manifold |

Drawing Preparation: The Foundation of Precision,3D Scanning & Drafting: Our professional engineers use advanced scanners to convert samples into 2D/3D drawings (7–10 days). |

||||||

Pattern & Sample Development: Where Time Invested Pays Off |

Complexity: Exhaust manifolds often require 3–5 sets of metal patterns (vs. 1 set for simpler castings).Lead Time: 35–40 days for multi-cavity patterns; 25–30 days for simpler designs. |

||||||

Initial Orders & Batch Production: Scaling Responsibly |

Machine Allocation: One manifold order may occupy 2–3 molding machines. Our 16-machine facility prioritizes urgent orders and collaborates with partner foundries for auxiliary cores. |

||||||

How Investors Can Mitigate Delays |

Allocate 8–12 weeks for pattern/sample development. Compressing this risks quality failures. First batches take 20–30% longer due to process fine-tuning. Post-approval, lead times stabilize. |

||||||

Pre-sales

On Sale

After-Sales

results→Welcome to contact us for your customized solution.

How did Dandong Pengxin Become a Top Manufacturer of Exhaust Manifold

Process designs derive from engineering drawings

3D scanners

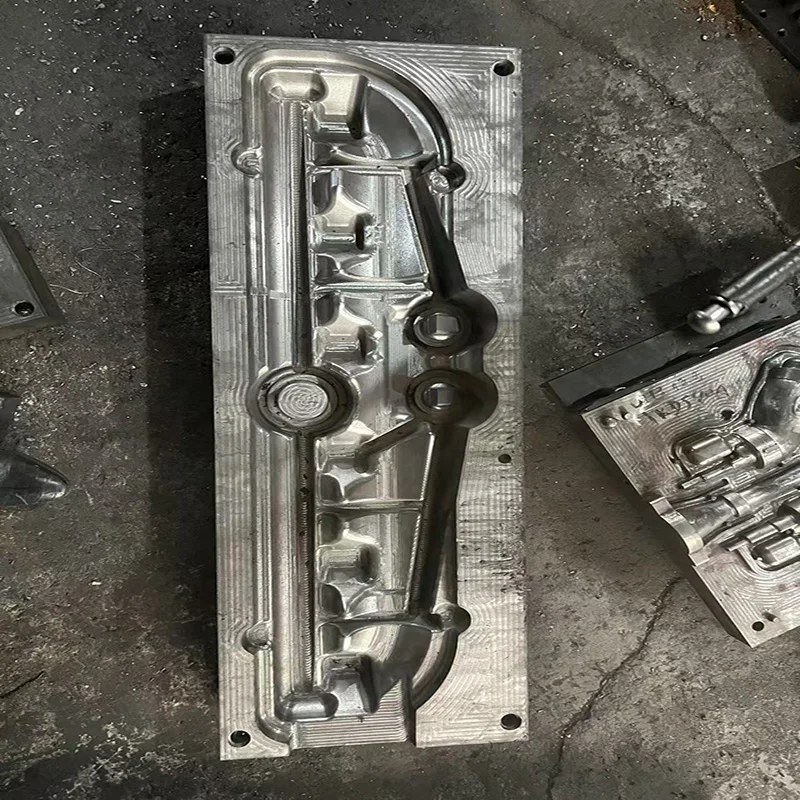

Metal Mold for Exhuast Manifold,Coated sand casting

Metal Mold for Exhaust Manifold,Sand Casting

Exhaust Manifold Core Box

Shell Molding Machine

Coated sand casting

Molding Machines

R&D

Production Capacity

Pattern Control

Abaqus,Moldflow and Moldex 3D, simulate feeding system, reduce casting defects and improve efficiency.

Raw Material Control

Machining Control