- Overview

- Recommended Products

The exhaust manifold is a critical engine component, responsible for collecting hot exhaust gases from multiple cylinders into a single pipe. Operating in an extreme environment of intense heat and cyclic fatigue, the choice of material is paramount for performance, durability, and cost. Understanding the different materials available is key to selecting the right manifold for your application.

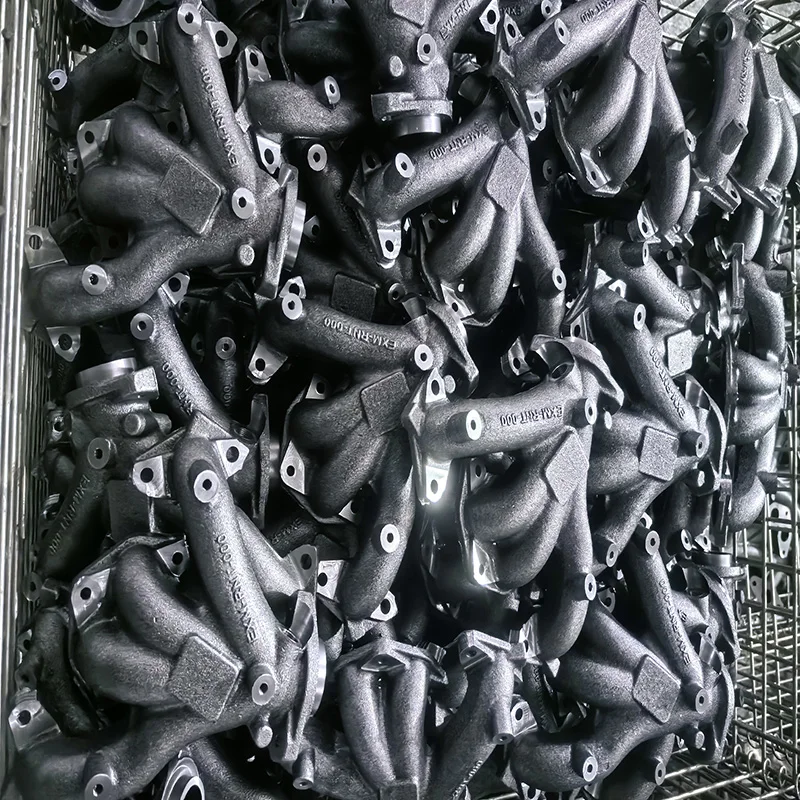

1. Cast Iron (Gray Iron and Compacted Graphite Iron)

Properties & Performance: This is the traditional and most common material for OEM manifolds, especially for standard passenger vehicles. Gray iron offers excellent castability, good heat resistance (withstanding temperatures up to ~700°C), and superior damping capacity to absorb vibration. Compacted Graphite Iron (CGI) provides a significant upgrade, offering higher tensile strength, better fatigue resistance, and improved thermal conductivity, making it suitable for more demanding applications.

Manufacturing Process: Typically produced via sand casting or shell molding, allowing for complex, integrated designs at a low cost.

Applications: Ideal for high-volume production of standard-duty manifolds for passenger cars and commercial vehicles.

2. Stainless Steel

Stainless steel is the preferred choice for high-performance and aftermarket manifolds, primarily due to its strength and thermal properties.

Properties & Performance: Grades like 304 and 321 austenitic stainless steel are popular. They offer exceptional high-temperature strength (resistant to warping and cracking up to ~900°C), superior thermal fatigue resistance, and good corrosion resistance. Their thinner walls can also improve exhaust gas flow and reduce weight.

Manufacturing Process: These manifolds are often fabricated from mandrel-bent tubing and TIG-welded, allowing for highly customized, performance-optimized designs (e.g., equal-length headers).

Applications: Widely used in racing cars, performance tuner vehicles, and heavy-duty applications.

3. Nodular Cast Iron (Ductile Iron)

Properties & Performance: Nodular iron offers a balance between the castability of gray iron and the strength of steel. Its spherical graphite nodules provide good ductility, high strength, and better impact and thermal shock resistance than standard gray iron.

Manufacturing Process: Like gray iron, it is primarily cast, making it suitable for complex geometries.

Applications: A cost-effective upgrade from gray iron for turbocharged engines or applications requiring a more robust solution without the cost of stainless steel.

Conclusion

The material selection for an exhaust manifold is a direct trade-off between performance, durability, and cost. While cast iron remains the economical choice for mass production, stainless steel is unmatched for high-performance and custom applications. Nodular iron serves as a robust middle ground. Partnering with an experienced manufacturer ensures the correct material is selected and precision-manufactured for your specific needs.

Why are we called OEM experts in Exhaust Manifolds |

We develop over 100 different types of exhaust manifolds every year |

||||||

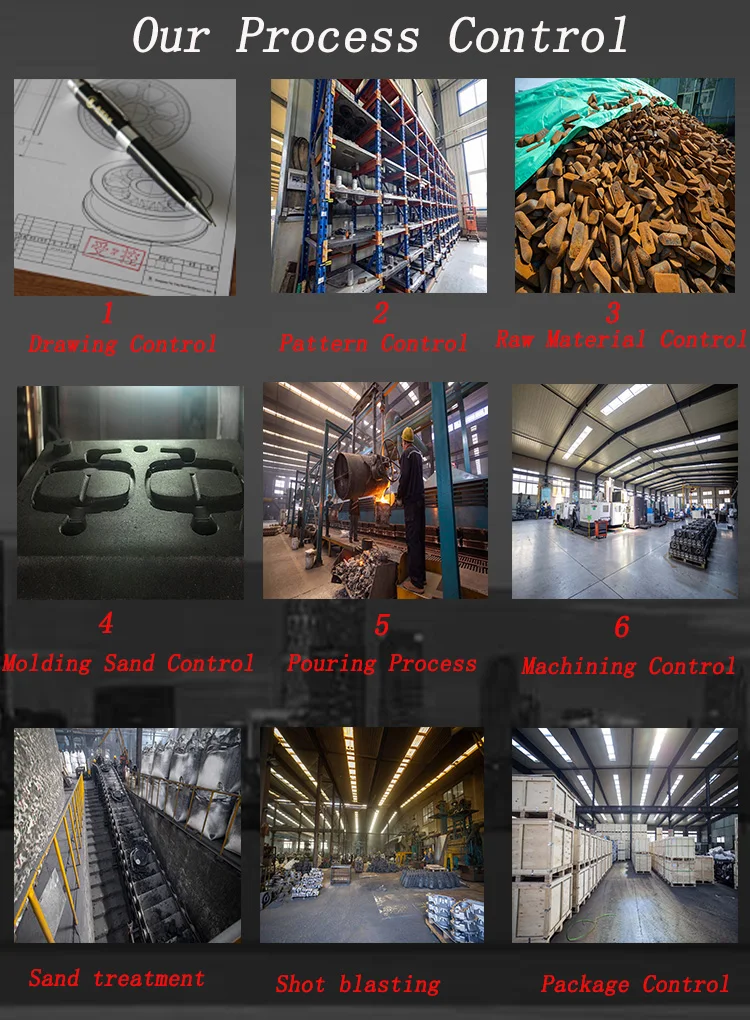

Dandong Pengxin Production Process for Exhaust Manifold |

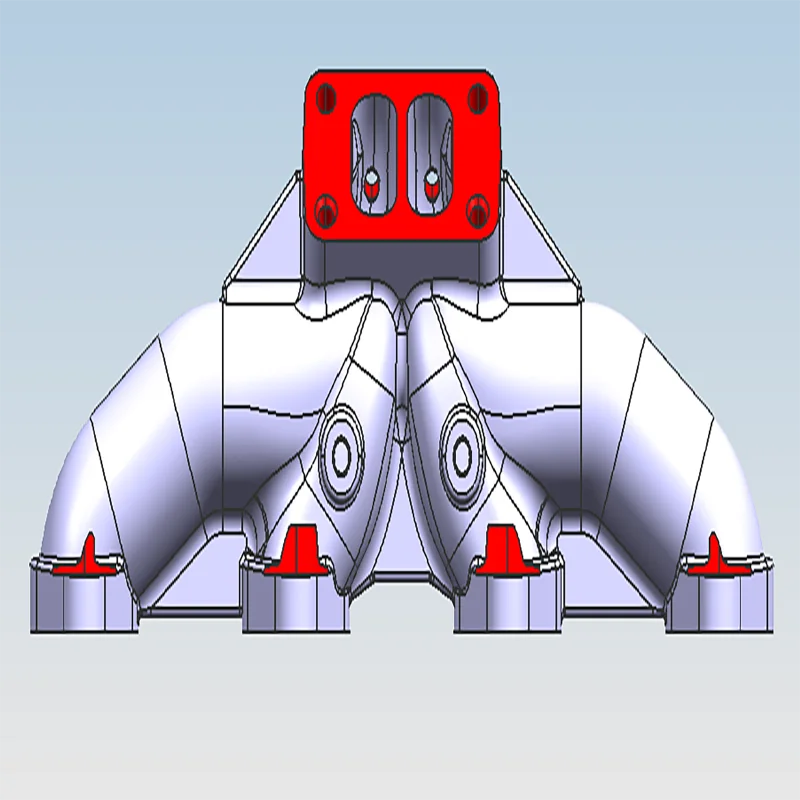

Drawing Preparation: The Foundation of Precision,3D Scanning & Drafting: Our professional engineers use advanced scanners to convert samples into 2D/3D drawings (7–10 days). |

||||||

Pattern & Sample Development: Where Time Invested Pays Off |

Complexity: Exhaust manifolds often require 3–5 sets of metal patterns (vs. 1 set for simpler castings).Lead Time: 35–40 days for multi-cavity patterns; 25–30 days for simpler designs. |

||||||

Initial Orders & Batch Production: Scaling Responsibly |

Machine Allocation: One manifold order may occupy 2–3 molding machines. Our 16-machine facility prioritizes urgent orders and collaborates with partner foundries for auxiliary cores. |

||||||

How Investors Can Mitigate Delays |

Allocate 8–12 weeks for pattern/sample development. Compressing this risks quality failures. First batches take 20–30% longer due to process fine-tuning. Post-approval, lead times stabilize. |

||||||

Pre-sales

On Sale

After-Sales

results→Welcome to contact us for your customized solution.

How did Dandong Pengxin Become a Top Manufacturer of Exhaust Manifold

Process designs derive from engineering drawings

3D scanners

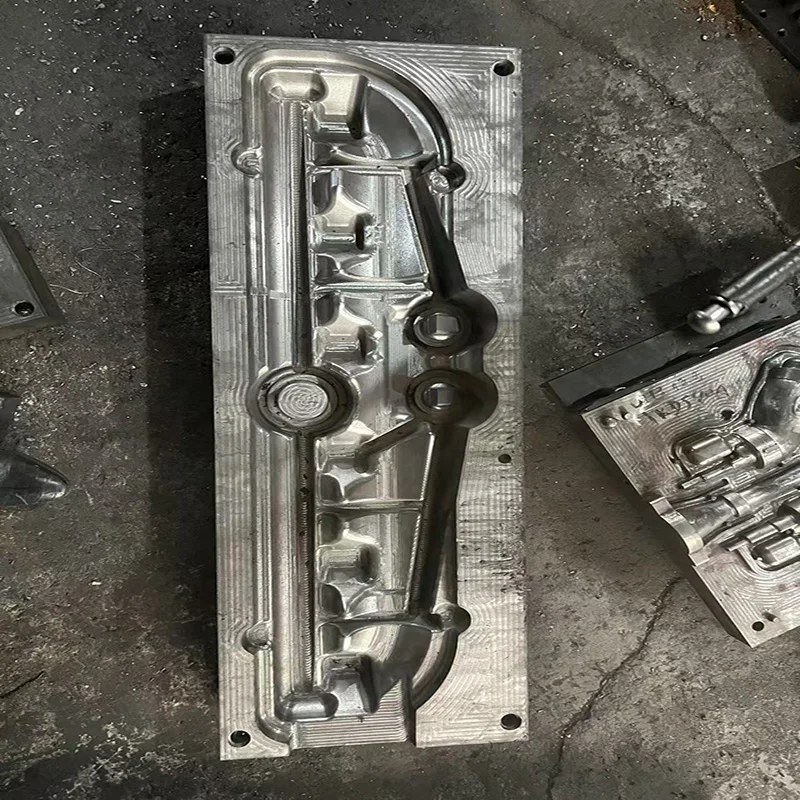

Metal Mold for Exhuast Manifold,Coated sand casting

Metal Mold for Exhaust Manifold,Sand Casting

Exhaust Manifold Core Box

Shell Molding Machine

Coated sand casting

Molding Machines

R&D

Production Capacity

Pattern Control

Abaqus,Moldflow and Moldex 3D, simulate feeding system, reduce casting defects and improve efficiency.

Raw Material Control

Machining Control