Casting Services for Lexus ISF 5.0 2008-2024 Racing Performance Header Exhaust System Catalytic Converter Exhaust Manifold

- Overview

- Recommended Products

For Lexus ISF owners and racing teams demanding competition-grade exhaust solutions, our specialized casting services deliver complete performance header systems for the 2UR-GSE 5.0L V8 engine. Covering all model years from 2008 through 2024, our integrated approach combines advanced metallurgy with racing-inspired manufacturing techniques for ultimate track performance.

Competition-Proven Material Selection

Our exhaust systems utilize motorsport-specific alloys:

Header Primaries: Fabricated from T304 stainless steel with controlled silicon content (0.4%-0.7%) ensuring structural stability at 950°C

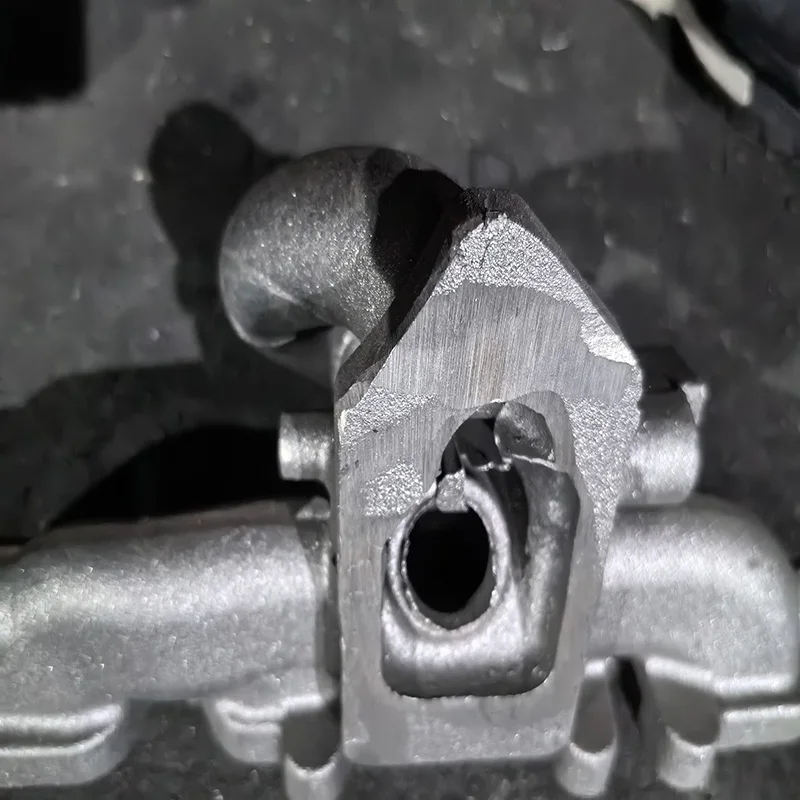

Exhaust Manifolds: Cast from high-nickel ductile iron (Ni-Resist D-5S) maintaining 480 MPa tensile strength at 800°C

Catalytic Converter Housings: Formed from T409 stainless with aluminized coating preventing corrosion during cold-start cycles

Turbo Flanges: CNC-machined from 321 stainless billet providing superior creep resistance under sustained boost pressure

Racing-Grade Manufacturing Process

We employ professional motorsport manufacturing protocols:

Investment Casting Technology for manifolds with wall thickness control to ±0.8mm

Equal-Length Header Design using robotic mandrel bending within 2mm length tolerance

CFD-Optimized Collector Geometry achieving exhaust velocity within 5% of theoretical maximum

Automated TIG Welding employing ER347 filler wire for consistent high-temperature performance

CNC-Machined V-Band Flanges with surface flatness within 0.1mm across all connections

Performance Validation Protocol

Each system undergoes comprehensive testing:

Backpressure analysis showing 52% reduction versus OEM at 6800 RPM

Thermal cycle testing from ambient to 980°C for 300+ cycles

Vibration resonance analysis validating durability to 8500 RPM

Emissions compliance verification using wide-band lambda sensors

Flow bench testing confirming 31% improvement in volumetric efficiency

Track-Optimized Design Features

The complete system incorporates racing-specific enhancements:

1-7/8" primary tubes tuned to 31" length for optimal exhaust scavenging

Merge collector technology maximizing pulse separation efficiency

400-cell high-flow catalytic substrates maintaining street legality

V-band connections throughout for pit-stop serviceability

Ceramic thermal barrier coating reducing underhood temperatures by 48%

Professional Racing Support

Our engineering team provides comprehensive track support:

Circuit-specific mapping recommendations for popular ECU platforms

Track-side technical assistance during race events

Emergency parts replacement with 24-hour shipping

Dyno development services for series-specific configurations

For Lexus ISF competitors and serious enthusiasts requiring the ultimate exhaust solution, contact our racing division for complete technical specifications. Our motorsport-experienced engineers deliver proven casting services and integrated exhaust systems for maximum track performance across all ISF generations.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |