- Overview

- Recommended Products

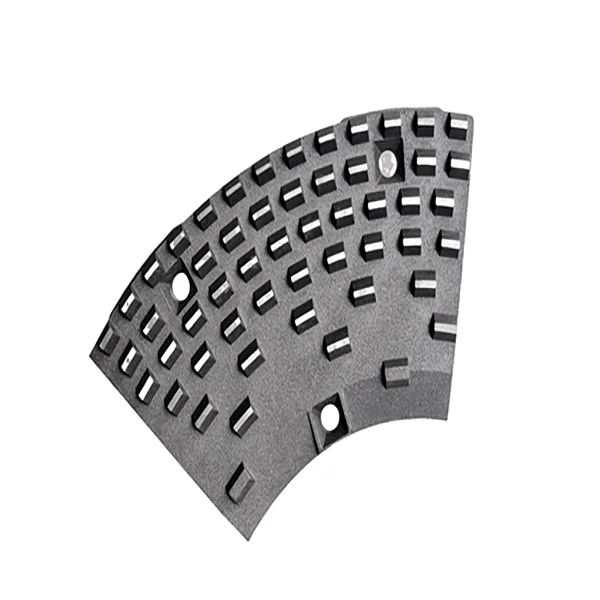

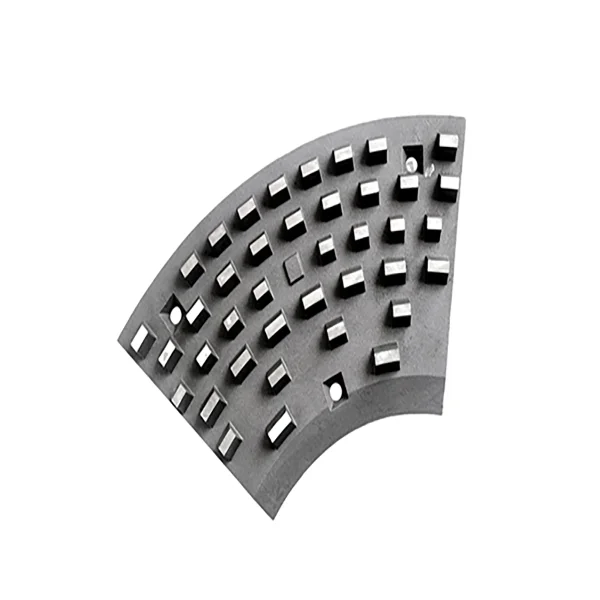

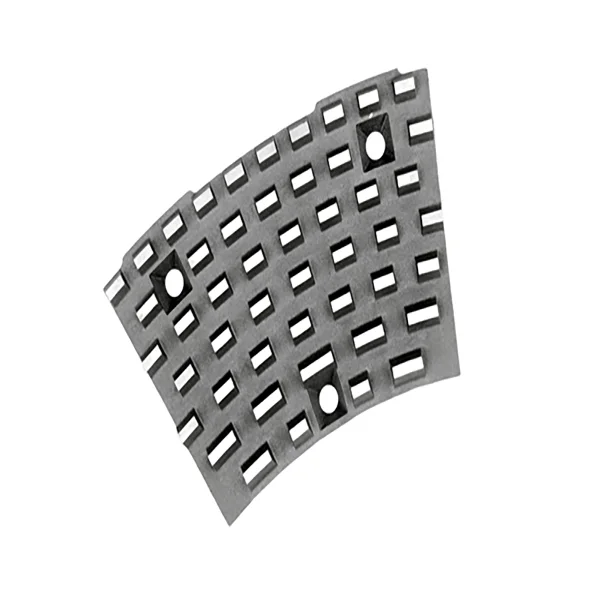

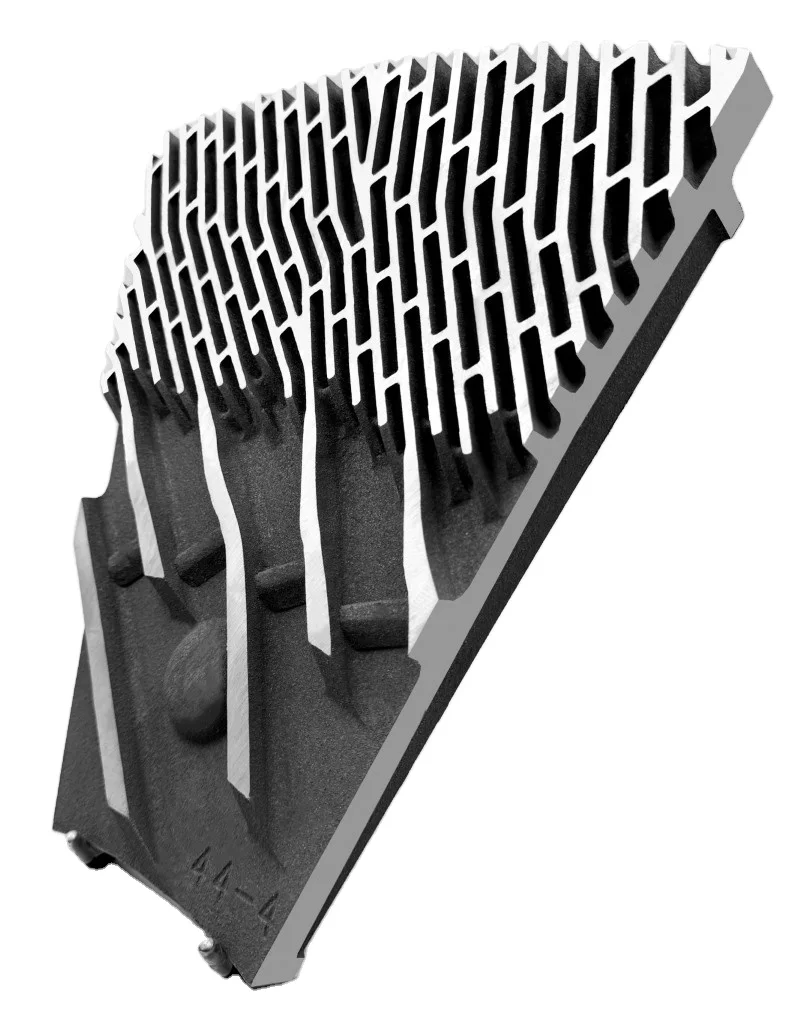

In high-capacity Medium-Density Fiberboard (MDF) production, the refiner mill stands as the core of fiber preparation, where grinding disc performance directly determines fiber quality and production efficiency. Our 54-Inch Segment Refiner Grinding Disc Plate represents the pinnacle of wear-resistant casting technology, engineered to deliver extended service life, consistent refining action, and optimal energy utilization in continuous MDF manufacturing operations.

Advanced Material Technology for Extreme Abrasion Resistance

We manufacture refiner segments using specialized high-chromium white iron alloys (ASTM A532 Class III Type A) with chromium content ranging 18-28%. These materials develop hypereutectic microstructures containing 30-45% hard chromium carbides (HV 1400-1800) within a tough metallic matrix. This composition delivers exceptional resistance to the severe three-body abrasion from wood lignins and mineral contaminants. The optimized carbide morphology and distribution ensure maintained hardness (58-65 HRC) at sustained operating temperatures up to 200°C, while providing sufficient fracture toughness to withstand mechanical impacts during start-up and foreign object events.

Precision Manufacturing Process with Controlled Metallurgy

Our production begins with CAD-optimized pattern equipment replicating exact bar and groove configurations. We employ high-density resin sand molding systems capable of maintaining dimensional stability for these large-scale components (Φ54-inch). The casting process utilizes controlled pouring temperatures and cooling rates to achieve directional solidification, preventing shrinkage defects in critical wear zones. Post-casting heat treatment follows a precisely documented protocol: destabilization at 950-1050°C, forced air quenching, and double tempering at 450-550°C to transform retained austenite while maintaining optimal hardness-toughness balance. Final CNC machining on large-diameter vertical lathes ensures mounting surface flatness within 0.1mm/m and precise bar height tolerances of ±0.15mm.

Performance-Optimized Application in MDF Refining

Our 54-inch segments deliver measurable operational benefits:

Service life extension of 40-60% compared to standard segments

Consistent fiber quality with stable freeness development (±15ml CSF)

Specific energy reduction of 8-12% through maintained plate geometry

Reduced maintenance downtime with predictable wear patterns

These segments are engineered for primary and secondary refiners in modern MDF lines, processing both virgin softwood/hardwood and recycled fiber sources. The precision-cast bar patterns maintain optimal fiber cutting and fibrillation actions throughout the wear cycle, directly influencing final board properties including internal bond strength (≥0.75MPa), thickness swelling (≤15%), and surface quality. Our technical team provides pattern selection guidance based on specific raw material characteristics and production targets, ensuring optimal refining intensity and fiber morphology development.

Each segment undergoes rigorous quality verification including:

Hardness mapping across multiple surface points

Dimensional inspection using laser scanning technology

Non-destructive testing (magnetic particle inspection)

Sample microstructure analysis

By combining advanced metallurgy with precision manufacturing, our 54-inch grinding disc plates help MDF producers achieve higher productivity, improved product quality, and reduced operating costs through extended service intervals and stable refining performance.

Product name: |

Grind segment |

Specification: |

14-16",17-18",20-24",26-30",42-48",52-58",CC450 |

Material: |

Nickel hard alloy Steel |

Usage: |

Inox Stainless Steel Metal |

Color: |

Natural |

Shape: |

Customized Shape |

Feature: |

Durable |

MOQ: |

1 Piece |

Warranty |

3 years |

ANDRITZ, a key player in the MDF and pulp and paper industry, manufacture it’s famous pressurized refining systems. The ANDRITZ single-disc refiners, equipped with the signature swing door design, enhance efficiency for plate changing process. Their comprehensive solution covers everything from debarking and chipping to screening, washing, and refining.

Q1. What is the advantage about your company? |

||||||||

A1. Our company has professional team and professional production line. |

||||||||

Q2. Why should I choose your products? |

||||||||

A2. Our products are high quality and low price. |

||||||||

Q3. The logo and the color can be customized? |

||||||||

A3. Yes, we welcome you to sample custom. |

||||||||

Q4. Any other good service your company can provide? |

||||||||

A4. Yes,we can provide good after-sale and fast delivery. |

||||||||