- 개요

- 추천 제품

정밀 제조 분야에서 CNC 텅스텐 카바이드 밀링 인서트는 첨단 절삭 기술의 정점으로, 가장 까다로운 가공 작업에서도 뛰어난 성능을 제공합니다. 이러한 고도화된 절삭 공구는 첨단 소재 과학과 정밀 엔지니어링을 결합하여 산업용 제조 공정에서 우수한 금속 제거 능력, 연장된 공구 수명 및 향상된 가공 효율성을 제공합니다.

고급 재료 구성

텅스텐 카바이드 인서트는 텅스텐과 탄소로 구성된 화합물인 WC 분말(텅스텐 카바이드 분말)로 제조되며, 이는 극도의 경도와 기능적 강도를 동시에 갖춘 독특한 특성을 지닙니다. 이 기본 재료는 일반적으로 코발트 결합제와 함께 특수 제조 공정을 통해 복합 구조를 형성하며, 고온 및 고응력 가공 조건에서도 절삭 성능을 유지할 수 있습니다. 이렇게 만들어진 재료 구조는 다양한 산업 분야에서 CNC 밀링 작업에 텅스텐 카바이드를 선호하는 주요 재료로 만드는 뛰어난 특성을 제공합니다.

입자 크기, 코발트 함량 및 기타 카바이드 첨가를 조절함으로써 특정 용도에 맞게 재료 조성을 맞춤화할 수 있으며, 특정 피가공재 및 가공 공정에 최적화된 전용 등급을 생성할 수 있습니다.

향상된 성능 특성

CNC 텅스텐 카바이드 밀링 인서트는 기계 가공 효율성 향상과 비용 절감으로 직접 이어지는 뛰어난 성능 특성을 제공합니다.

뛰어난 경도: 경도 값이 Hv 1100-2200(약 HRC 40-65)에 달하는 텅스텐 카바이드는 기존의 공구 재료보다 훨씬 오랫동안 절삭 날을 유지합니다. 이러한 극한의 경도는 마모에 대한 저항력을 뛰어나 도구 수명 동안 일관된 성능을 보장합니다.

우수한 내열성: 이러한 인서트는 고속 가공 작업 중 발생하는 고온에서도 구조적 완전성과 절삭 능력을 유지합니다. 이 소재는 열 변형에 강해 절삭 속도와 이송 속도를 증가시킬 수 있으며, 사이클 타임을 크게 단축시킵니다.

탁월한 내마모성: 높은 경도와 최적화된 금속조직 구조의 조합은 마모, 부착, 확산 마모 등 다양한 마모 메커니즘에 대해 뛰어난 저항성을 제공합니다. 이는 공구 수명을 연장시키고 부품당 가공 비용을 절감하는 효과로 이어집니다.

정밀 제조 공정

고급 텅스텐 카바이드 인서트의 생산에는 일관된 품질과 성능을 보장하는 정교한 제조 기술이 필요합니다.

분말 금속학

제조 공정은 텅스텐 카바이드 분말 생산으로 시작되며, 여기서 텅스텐 산화물을 수소로 환원하여 미세한 텅스텐 분말을 만들고, 이후 1400~1700°C의 온도에서 탄화 처리하여 텅스텐 카바이드 분말을 형성합니다. 이 분말은 특정 성능 특성을 달성하기 위해 입자 크기와 분포가 정밀하게 제어됩니다.

성형 및 소결

분말 압출 성형(PIM)과 같은 첨단 성형 기술을 통해 높은 치수 정확도를 갖는 복잡한 인서트 형상을 생산할 수 있습니다. 성형된 인서트는 진공 로에서 1300~1500°C의 온도 범위에서 정밀하게 제어된 소결 공정을 거치며, 고성능 탄화물 공구의 특징인 조밀하고 경화된 구조를 형성합니다.

코팅 기술

최신 탄화물 인서트는 화학 기상 증착(CVD) 또는 물리 기상 증착(PVD) 공정을 통해 적용되는 특수 표면 코팅을 자주 포함합니다. MT-TiCN+Al2O3+TiN 및 실리콘+TiAlN과 같은 다층 코팅은 마모 저항성을 더욱 향상시키고, 마찰을 줄이며 열 보호 성능을 개선합니다.

범용적 용도

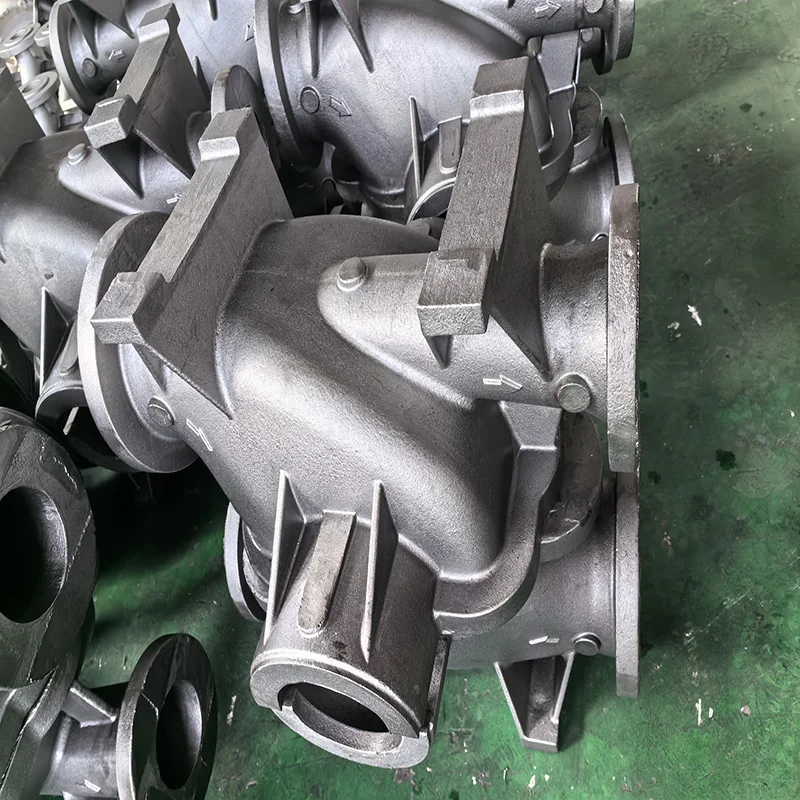

CNC 텅스텐 탄화물 밀링 인서트는 다양한 산업용 가공 응용 분야에 사용됩니다:

재료별 가공

강 및 합금강 가공: 저탄소강부터 고합금 공구강까지 다양한 강재 가공에 최적화된 성능을 제공하는 특수 등급의 CVD 코팅 제품

스테인리스강 가공: 엣지 인성 향상된 PVD 코팅 등급이 까다로운 스테인리스강 소재 가공 시 안정적인 성능을 제공합니다

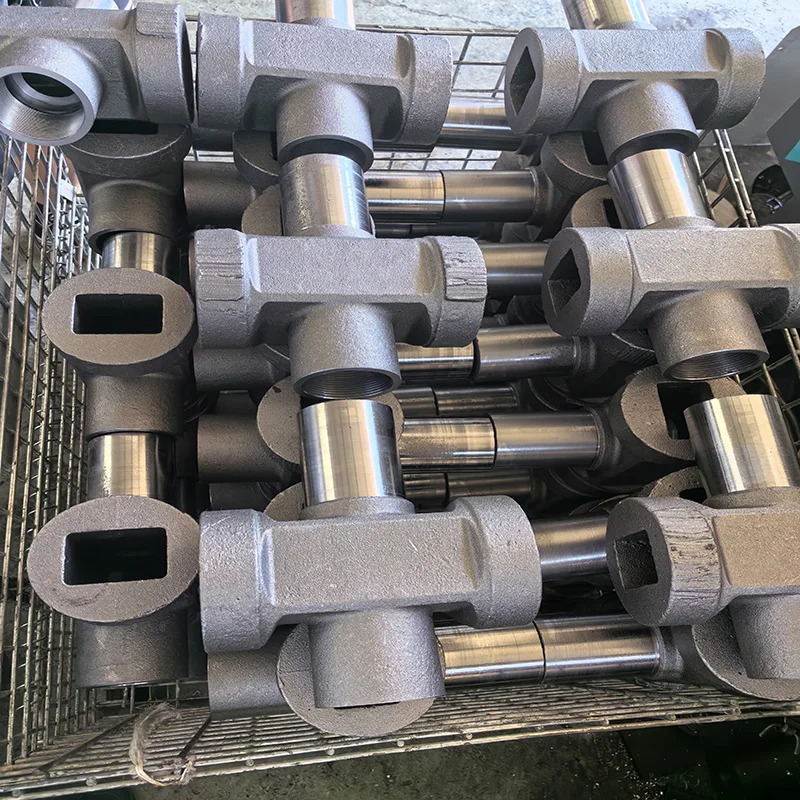

주철 응용 분야: 회백주철 및 연성주철 가공 작업을 위해 특별히 설계된 전용 형상 및 등급

공정별 맞춤 솔루션

조업 가공: 다량의 재료 제거를 위해 설계된 강한 절삭 날과 칩브레이커를 갖춘 견고한 인서트 형상

정밀가공: 예리한 절삭 날을 가진 정밀 그라인딩 인서트로 우수한 표면 마감과 높은 치수 정밀도를 구현

단속 절삭: 충격에 저항하는 기질을 가진 고인성 등급 인서트가 어려운 가공 조건에서도 성능을 유지

기술 혁신 및 맞춤화

주요 제조업체들은 비표준 탄화물 제품에 대해 OEM 및 ODM 서비스를 포함한 포괄적인 맞춤 제작 기능을 제공합니다

재질 |

강철, 스테인레스 강, 알루미늄, 철, 탄소 강, 구리, 브라스, 합금 등 |

두께 |

0.1mm에서 12mm까지, 요청에 따라 |

사이즈 |

1) 고객 사양서에 따라 2) 고객 샘플에 따라 |

표면 처리 |

아노다이징, 갈바니화, 아연 도금, 니켈 도금, 크롬 도금, 분말 도료, 도장 등 |

도면 형식 |

DWG, DXF, STEP, STP, STL, AI, PDF, JPG, 초안. |

포장 |

폴리백+카톤 상자+나무 상자/팔레트, 고객 요청에 따라 |

배송 |

1) DHL, TNT, Fedex 등 택배로 보낼 경우 일반적으로 5-7일 소요 |

2) 공항으로 항공 운송 시 일반적으로 3-4일 소요 |

|

3) 선적 항구로 해상 운송 시 일반적으로 15-30일 소요 |

|

배송 시간 |

수량에 따라 다릅니다. 일반적으로 20일 정도입니다. |

지급 조건 |

T/T, Paypal, 트레이드 어시ュ어런스 |

인증 |

Iso |

로고 서비스 |

제공된 |

응용 |

건설, 산업, 자동차 산업에서 널리 사용됩니다. |