- Overview

- Recommended Products

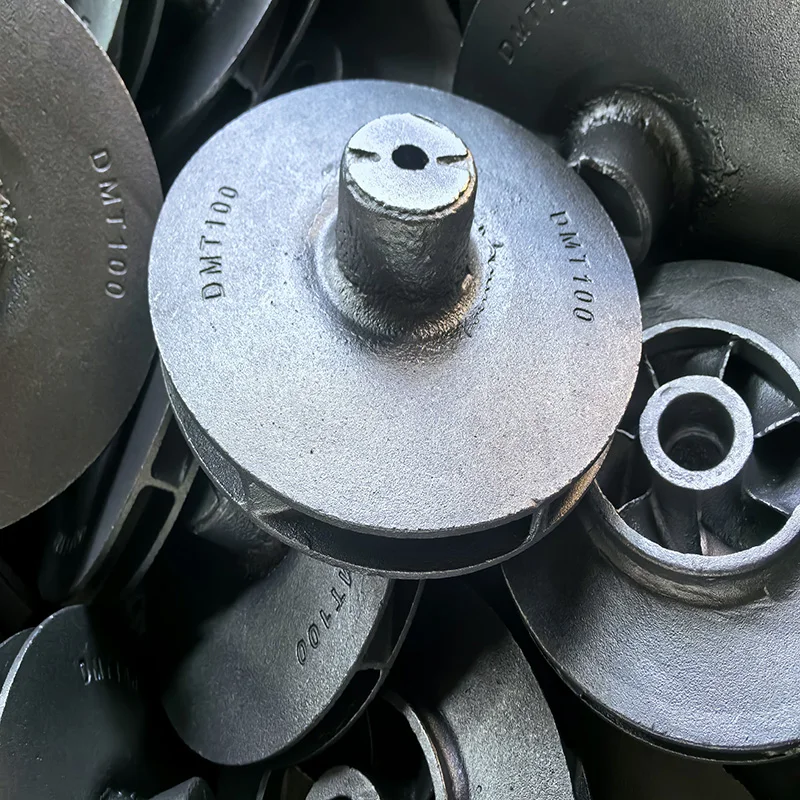

Stainless steel investment casting, also known as the lost-wax process, represents one of the most versatile and precise manufacturing methods for producing complex, high-quality custom parts and components. This advanced casting technology enables the creation of intricate geometries with exceptional dimensional accuracy and superior surface finishes, making it ideal for applications across aerospace, medical, automotive, and industrial sectors where precision and reliability are paramount.

Material Selection and Performance Characteristics

Our investment casting services utilize a comprehensive range of stainless steel alloys, each selected for specific performance requirements:

304/L Stainless Steel: Excellent corrosion resistance, tensile strength 515-620 MPa, yield strength 205-310 MPa

316/L Stainless Steel: Superior chloride resistance, PREN >25, tensile strength 485-515 MPa

17-4PH Stainless Steel: Precipitation hardening capability, tensile strength 795-1000 MPa, yield strength 690-860 MPa

410 Stainless Steel: Martensitic structure, tensile strength 485-795 MPa, hardness 35-40 HRC

These materials demonstrate outstanding mechanical properties including excellent corrosion resistance, high temperature performance (up to 815°C for some grades), good impact toughness, and maintained strength across various operating conditions.

Advanced Investment Casting Manufacturing Process

Our precision manufacturing process integrates multiple sophisticated stages:

Pattern Creation:

Rapid prototyping and CNC-machined wax pattern production

Advanced 3D printing technology for complex geometries

Multi-cavity mold designs for production efficiency

Quality verification of wax patterns before shell building

Shell Building Process:

Multi-layer ceramic shell application using zircon-based primary coats

Successive dipping in refractory slurries with silica sand stuccoing

Controlled drying between each coating application

High-temperature autoclave dewaxing and firing (1000-1100°C)

Metal Processing:

Vacuum melting and precision pouring under controlled atmosphere

Advanced gating system design for optimal metal flow

Controlled solidification technology

Heat treatment per specific material requirements

Quality Assurance and Technical Specifications

Each component undergoes comprehensive validation:

Chemical composition analysis using optical emission spectroscopy

Mechanical property testing per ASTM/ISO standards

Dimensional inspection using CMM technology (±0.02 mm accuracy)

X-ray and liquid penetrant testing for defect detection

Surface finish measurement: Ra 1.6-3.2 μm achievable

Our investment casting services maintain rigorous quality parameters:

Dimensional tolerance: ±0.005 mm/mm for linear dimensions

Minimum wall thickness: 1.0 mm for small to medium components

Casting weight range: 0.01 kg to 50 kg per piece

Position tolerance: ±0.13 mm for critical features

Industry Applications and Customization Capabilities

Our custom stainless steel components serve critical functions across multiple sectors:

Aerospace and Defense:

Turbine blades and engine components

Structural brackets and fittings

Defense system components

Medical and Dental:

Surgical instruments and implants

Medical device components

Dental and orthopedic devices

Automotive and Transportation:

Engine and transmission components

Fuel system parts

Performance racing components

Industrial Applications:

Valve bodies and pump components

Food processing equipment

Marine and offshore hardware

Technical Advantages and Performance Benefits

The investment casting process provides significant advantages:

Complex geometry capability without additional assembly

Excellent surface finish reducing secondary operations

Material consistency and metallurgical integrity

Design flexibility for optimized component performance

Cost-effectiveness for medium to high volume production

Superior mechanical properties through controlled processing

Our stainless steel investment casting services combine advanced manufacturing technology with comprehensive quality control, delivering custom components that meet the most demanding application requirements. The integration of modern foundry practices with rigorous testing ensures consistent quality across production batches, making investment casting the preferred manufacturing method for complex stainless steel components where precision, reliability, and performance are critical to success.

Our Services |

CNC Precision Milling Machining,CNC Precision Turning Machining, Rapid Prototyping Plastic Injection Mould Metal Stamping, Die Casting, Silicone And Rubber Mould, Aluminum Extrusion, Mould Fabrication,etc |

Material |

Aluminum Alloy:5052/6061/6063/7075 etc Brass Alloy: 3602/2604/h59/h62/etc Stainless Steel Alloy: 303/304/316/412/etc Steel Alloy: Carbon/Die Steel/etc Other Special Materials: Lucite/Nylon/Bakelite/etc Plastic, Wood, Silicone, Rubber,Or as per the customers’ requirements |

Surface Treatment |

Anodizing, Sandblasting, Painting, Powder coating, Electroplating, Silk Printing, Brushing, Polishing, Laser Engraving... |

Drawing Format |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl,etc |

Service Project |

To provide project design, production and technical service, mould development and fabrication, etc |

Testing Machine |

Digital Height Gauge, caliper, Three Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

Quality Assurance |

ISO9001:2015 Certified TUV |

Packing |

Foam, Carton, Wooden boxes, or as per the customer’s requirements |

Deliver |

DHL, FEDEX, UPS, TNT, EMS, SF Or according to customers′ requirement |