- Overview

- Recommended Products

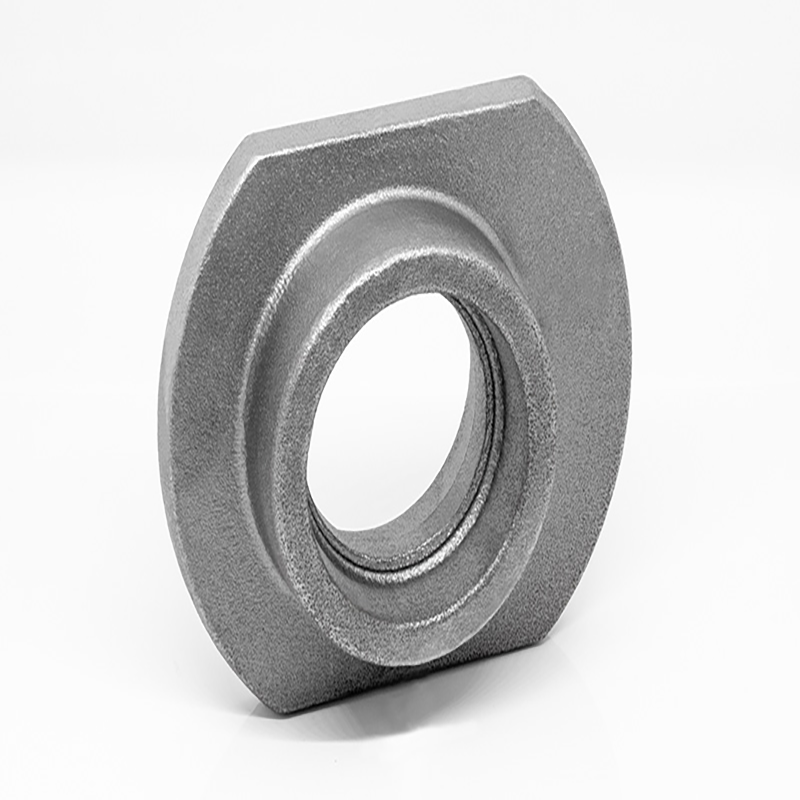

Introducing, the Pengxin OEM Steel Forge Services Cold Forging Press - the ultimate solution for efficient metal materials processing. This high-quality product is designed to meet the needs of manufacturers and industries looking for precision and reliability in their forging operations.

Constructed with the latest technology and durable materials, the Pengxin Cold Forging Press is built to last. Its sturdy steel frame ensures stability and durability, even when working with the toughest metal materials. This press is perfect for a wide range of applications, from automotive parts to industrial components.

One of the key advantages of this cold forging press is its ability to work with a variety of metal materials. Whether you need to forge steel, aluminum, brass, or other metals, the Pengxin press can handle it with ease. Its versatility makes it an essential tool for any manufacturer looking to streamline their metal processing operations.

In addition to its versatility, the Pengxin Cold Forging Press is also incredibly efficient. Thanks to its innovative design and advanced technology, this press can produce high-quality forged parts quickly and accurately. Its precision engineering ensures that every piece meets the exact specifications required by the customer.

Furthermore, the Pengxin Cold Forging Press is designed to be easy to use and maintain. Its user-friendly interface allows operators to control the machine with ease, while its low-maintenance design ensures that downtime is kept to a minimum. This means that manufacturers can rely on this press to keep their production lines running smoothly without any interruptions.

The Pengxin OEM Steel Forge Services Cold Forging Press is a top-of-the-line product that delivers exceptional performance and reliability. Its high-quality construction, versatility, efficiency, and user-friendly design make it an essential tool for any manufacturer looking to improve their metal materials processing operations. Invest in the Pengxin Cold Forging Press today and take your manufacturing process to the next level

Material |

Aluminum, gray cast iron, ductile iron, stainless steel, copper, brass, galvanized etc |

||||||

Size |

Customized |

||||||

Surface treatment |

Powder coating, electroplating, oxide, anodization |

||||||

Technics |

laser cut, bend, weld, stamp, casting, forging |

||||||

Certification |

ISO9001:2015 |

||||||

OEM |

Accept |

||||||

Drawing Format |

3D/CAD/Dwg/IGS/STEP |

||||||

Color |

Customized |

||||||

Application |

Appliance, Auto, Building, Capital equipment, Energy, Instrumentation, Medical device, Telecommunications |

||||||

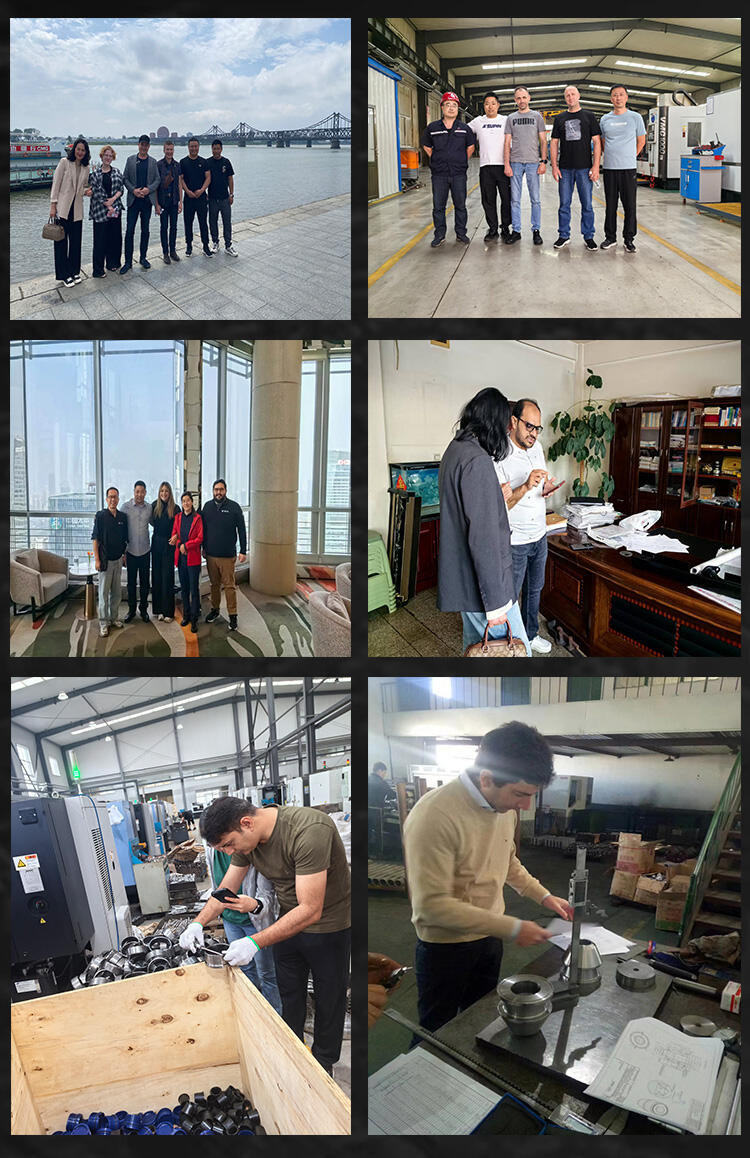

Who We Are

Pre-sales

On Sale

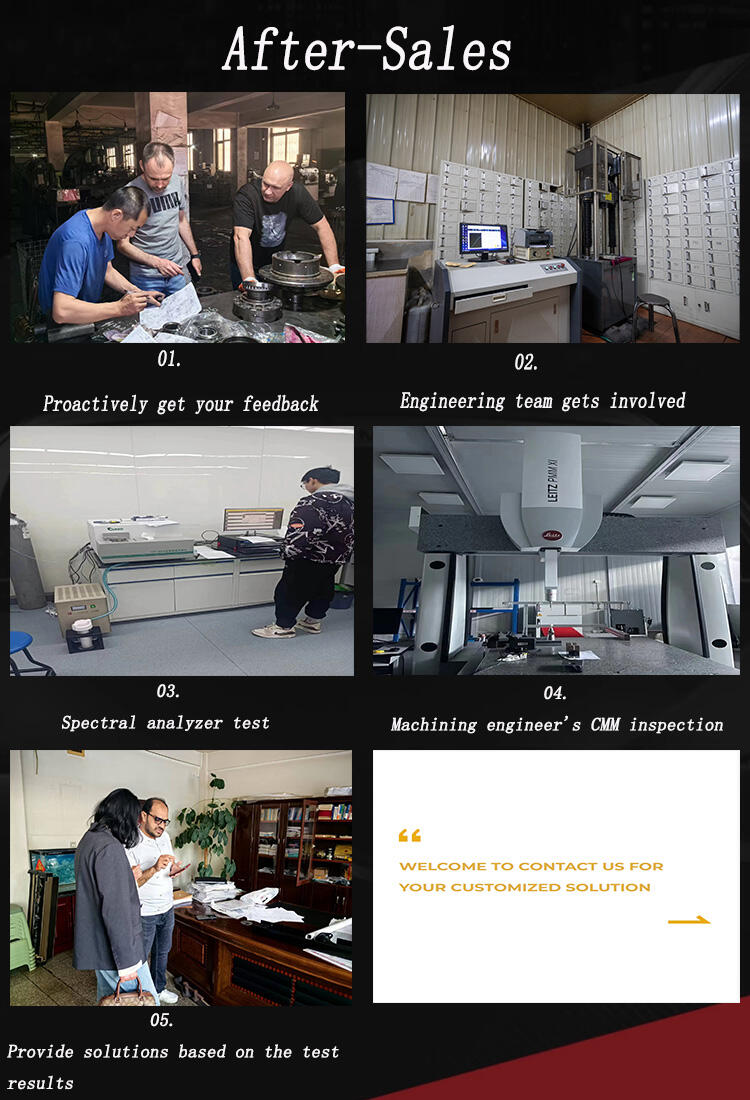

After-Sales

30,000 tons+Annual production capacity for Aluminum

80,000 tons+Annual production capacity for Steel

4000+Mold develop production

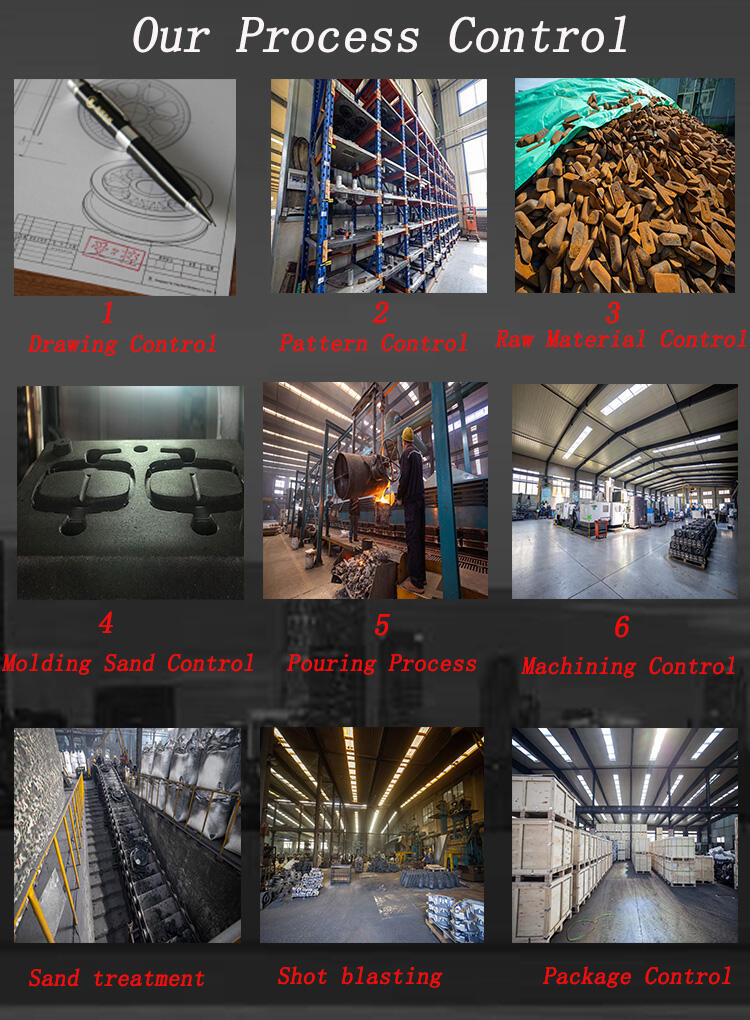

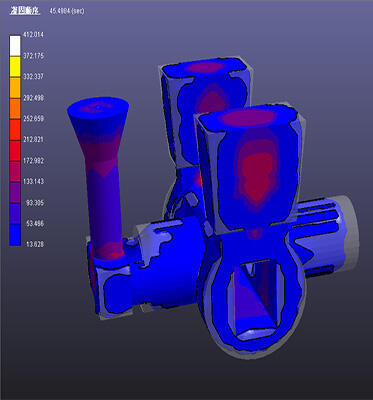

Quality Control

Pattern Control

Raw Material Control

Raw Casting & Machining Control