In fluid control systems across industrial sectors, valve components manufactured through resin sand casting represent the optimal balance of performance, durability, and cost-effectiveness. Our specialized foundry services focus on producing ductile cast iron valve parts using advanced resin sand casting technology, delivering components that meet stringent pressure integrity and service life requirements. This manufacturing approach provides valve manufacturers with precision-cast parts capable of withstanding demanding operational conditions while maintaining consistent quality across production volumes.

Material Excellence and Performance Characteristics

We utilize high-grade ductile iron (Grades 40018, 50007, 60003) specifically engineered for valve applications, providing tensile strength of 400-600 MPa, yield strength of 250-350 MPa, and elongation of 10-18% depending on grade requirements. The spherical graphite microstructure delivers exceptional impact resistance (Charpy V-notch values of 12-20 J at 20°C) and superior fatigue strength, with pressure cycling endurance exceeding 10^7 cycles at rated working pressure. The material's combination of mechanical properties ensures reliable performance across temperature ranges from -20°C to 350°C, with excellent resistance to water hammer effects and thermal cycling that commonly challenge valve components in service.

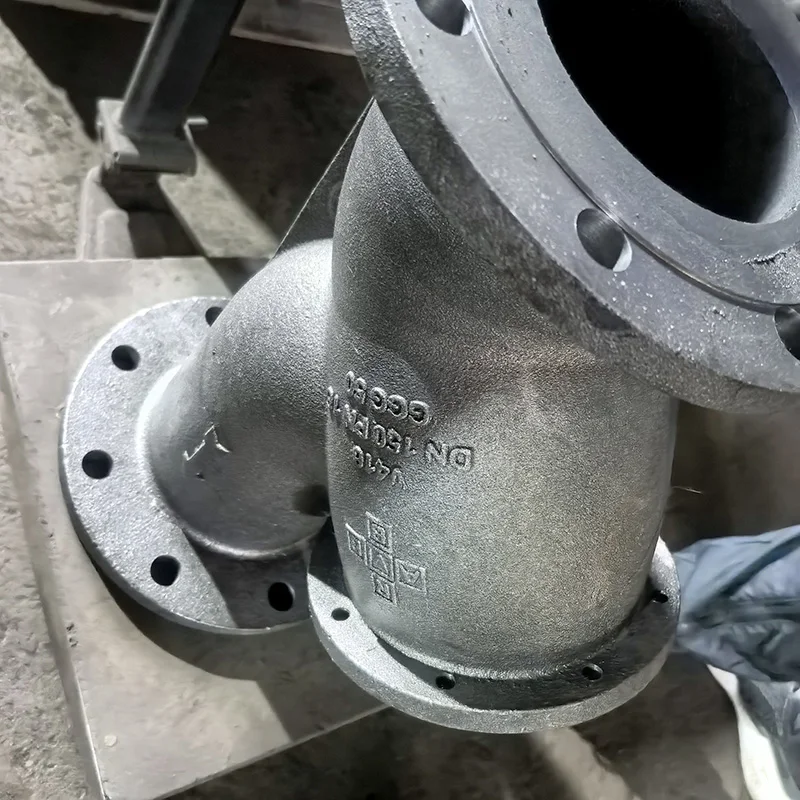

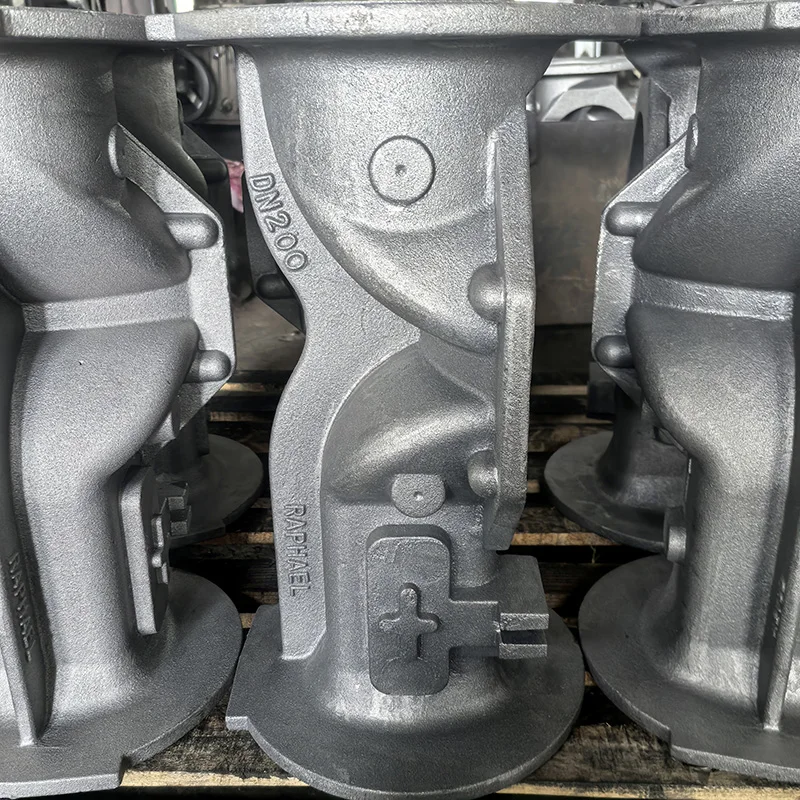

Precision Resin Sand Casting Process

Our manufacturing employs phenolic urethane-bonded sand systems that maintain dimensional stability within ±0.002 inches per inch for complex valve geometries. The process begins with precision pattern equipment designed with optimized gating and feeding systems to ensure sound castings in critical sealing areas. Controlled pouring in climate-regulated environments prevents gas entrapment and shrinkage defects, while real-time thermal monitoring guarantees proper solidification patterns. Each valve part undergoes precision machining on CNC boring mills and lathes, maintaining bore tolerances within IT8 standards and surface finishes of 3.2 μm Ra for sealing surfaces. The process includes comprehensive quality verification through pressure testing, dimensional inspection, and material certification.

Comprehensive Valve Applications

Our resin sand cast ductile iron valve parts serve essential functions across multiple fluid handling sectors including water distribution systems (gate valves, butterfly valves), industrial processing (ball valves, globe valves), and energy generation (control valves, isolation valves). The chemical processing industry utilizes our components for valves handling corrosive media, while the oil and gas sector specifies our parts for pipeline valves requiring API standards compliance. Additional applications include marine valve systems, irrigation control valves, and fire protection valves where reliability and pressure integrity are critical safety considerations.

Partner with our foundry for resin sand cast ductile iron valve parts that combine metallurgical excellence with manufacturing precision. Our technical expertise in both ductile iron metallurgy and valve component engineering ensures solutions that enhance valve performance, reduce lifecycle costs, and provide reliable service across diverse fluid handling applications, supported by comprehensive quality documentation and performance validation.

About Us