Spanning 66,000 m² with 40,000 m² of workshops, it has $40M in assets and 330 employees, including 46 technical staff. Annual capacity reaches 100,000 tons

- Overview

- Recommended Products

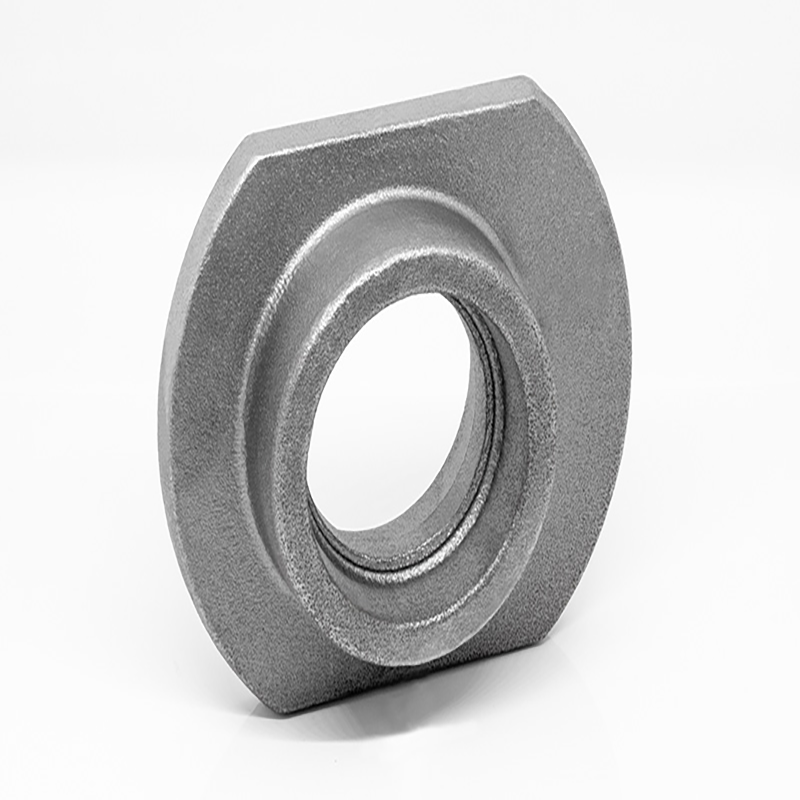

Introducing the Pengxin OEM Steel Forge Services Cold Forging Press, the ultimate solution for efficient metal materials processing. This innovative product is designed to meet the demands of industrial manufacturing, providing reliable and precise forging capabilities to streamline production processes

With a focus on quality and efficiency, the Pengxin Steel Forge Services Cold Forging Press is the ideal choice for businesses looking to enhance their metalworking operations. This state-of-the-art machine utilizes cold forging technology to shape and mold metal materials with precision and consistency. By utilizing cold forging techniques, this press is able to produce high-quality parts and components without the need for excessive heat or energy consumption

The Pengxin Cold Forging Press is built to last, with a durable steel construction that ensures long-lasting performance and reliability. The machine is designed to withstand the rigors of heavy-duty industrial use, making it a valuable investment for any manufacturing operation. Additionally, the press is equipped with advanced features and controls that allow for easy operation and adjustment, ensuring optimal results with every use

One of the key advantages of the Pengxin Cold Forging Press is its ability to increase productivity and efficiency in metal materials processing. By utilizing cold forging technology, this machine is able to achieve high levels of precision and accuracy in shaping metal materials, resulting in minimal waste and improved product quality. This translates to increased production rates and reduced lead times, helping businesses meet their production goals with ease

In addition to its superior performance capabilities, the Pengxin Cold Forging Press also offers a cost-effective solution for metalworking operations. By minimizing the need for excessive heat and energy consumption, this machine helps businesses reduce their operating costs and improve their bottom line. With its efficient design and reliable operation, the Pengxin Cold Forging Press is a smart investment for any business looking to optimize their metal materials processing capabilities

The Pengxin OEM Steel Forge Services Cold Forging Press is a top-of-the-line solution for efficient and reliable metalworking. With its advanced features, durable construction, and cost-effective operation, this machine is an essential tool for businesses looking to enhance their manufacturing processes. Invest in the Pengxin Cold Forging Press today and experience the benefits of efficient metal materials processing

Material |

Aluminum, gray cast iron, ductile iron, stainless steel, copper, brass, galvanized etc |

||||||

Size |

Customized |

||||||

Surface treatment |

Powder coating, electroplating, oxide, anodization |

||||||

Technics |

Laser cut, bend, weld, stamp, casting, forging |

||||||

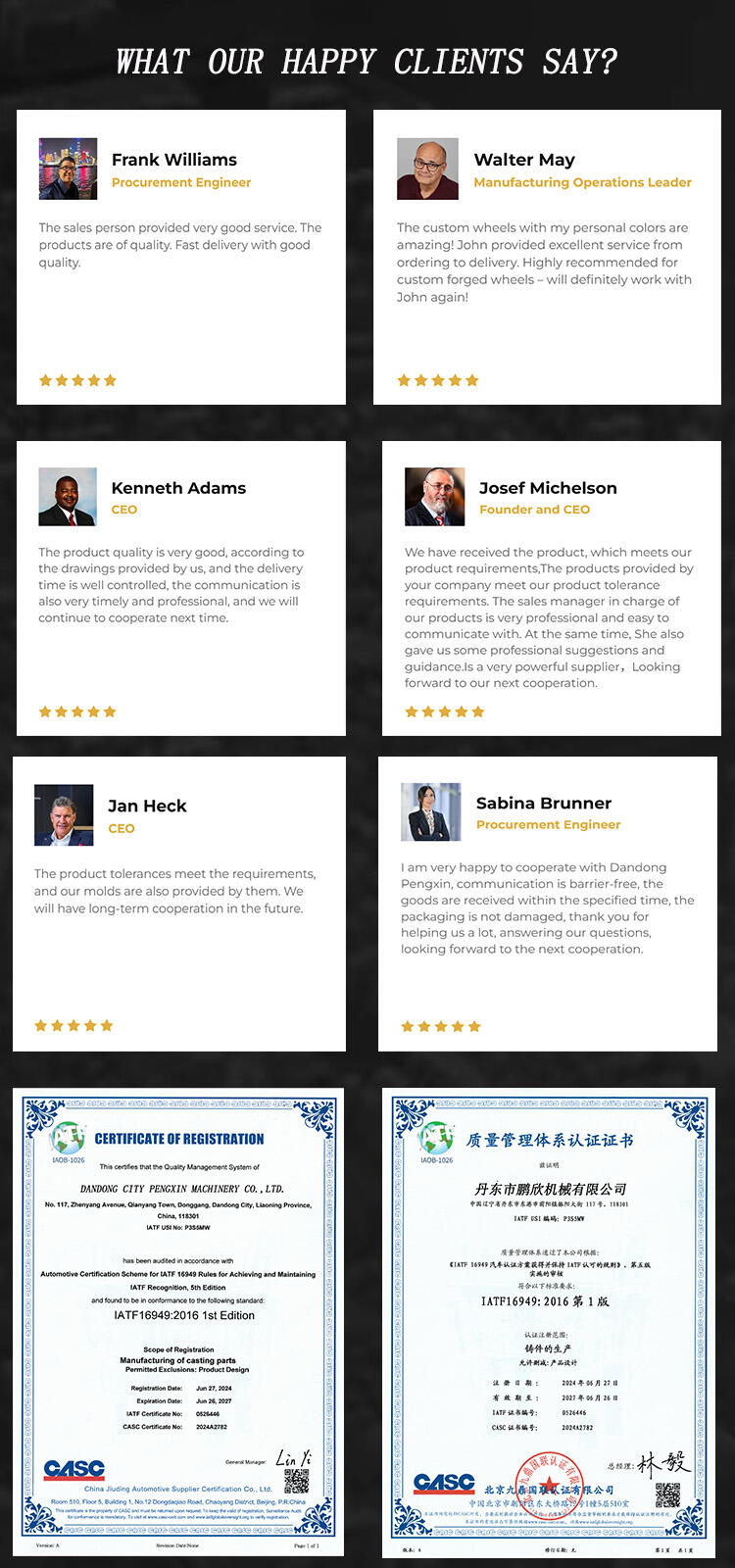

Certification |

ISO9001:2015 |

||||||

OEM |

Accept |

||||||

Drawing Format |

3D/CAD/Dwg/IGS/STEP |

||||||

Color |

Customized |

||||||

Application |

Appliance, Auto, Building, Capital equipment, Energy, Instrumentation, Medical device, Telecommunications |

||||||

Spanning 66,000 m² with 40,000 m² of workshops, it has $40M in assets and 330 employees, including 46 technical staff. Annual capacity reaches 100,000 tons

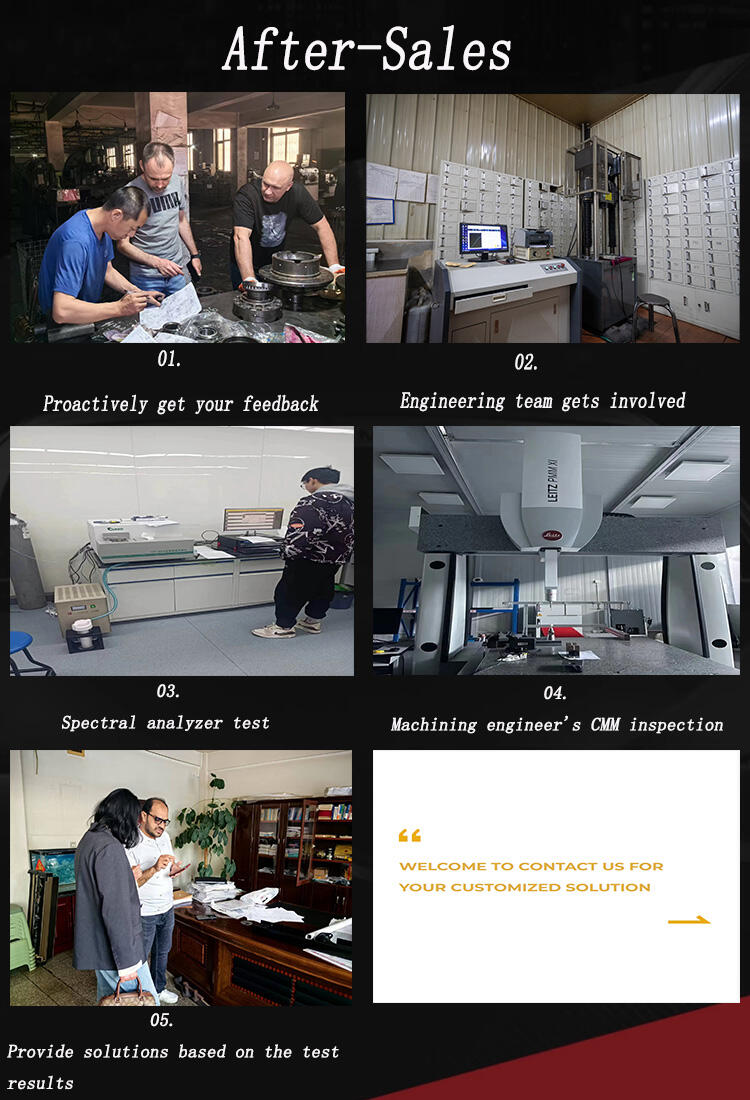

Pre-sales

On Sale

After-Sales

30,000 tons+Annual production capacity for Aluminum

80,000 tons+Annual production capacity for Steel

4000+Mold develop production

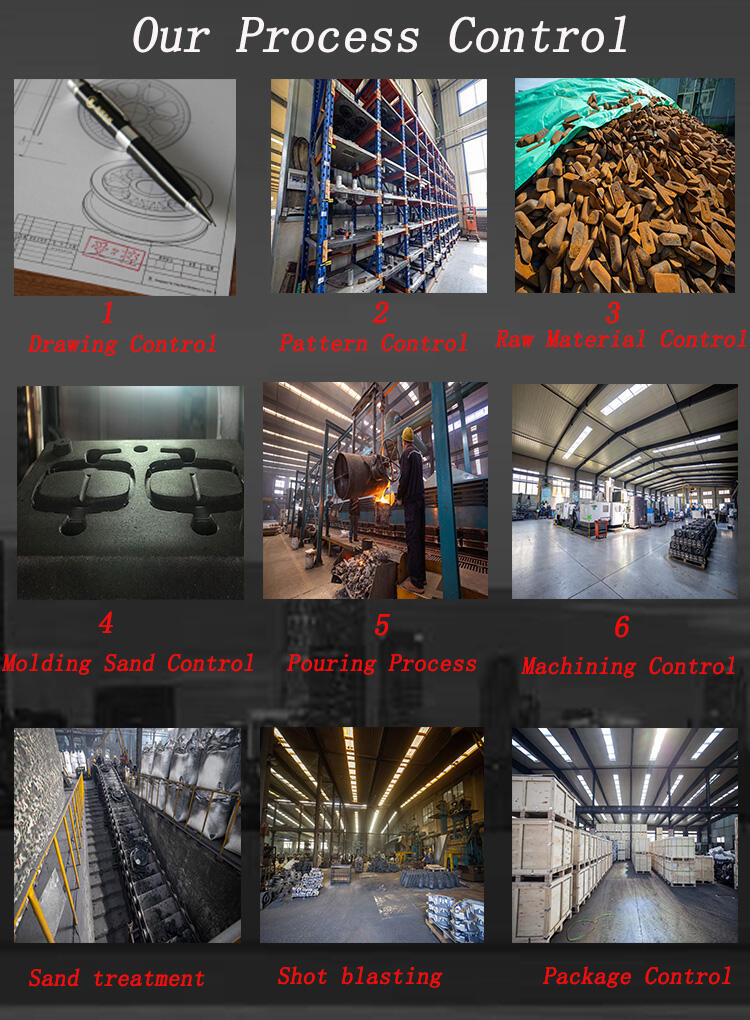

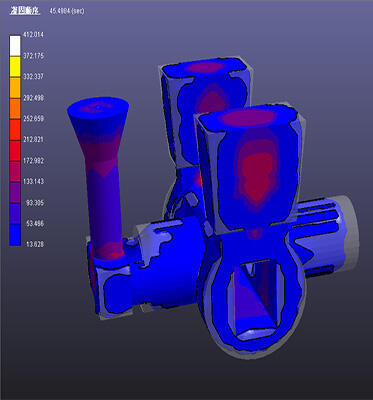

Quality Control

Pattern Control

Raw Material Control

Raw Casting & Machining Control