Spanning 66,000 m² with 40,000 m² of workshops, it has $40M in assets and 330 employees, including 46 technical staff. Annual capacity reaches 100,000 tons

- Overview

- Recommended Products

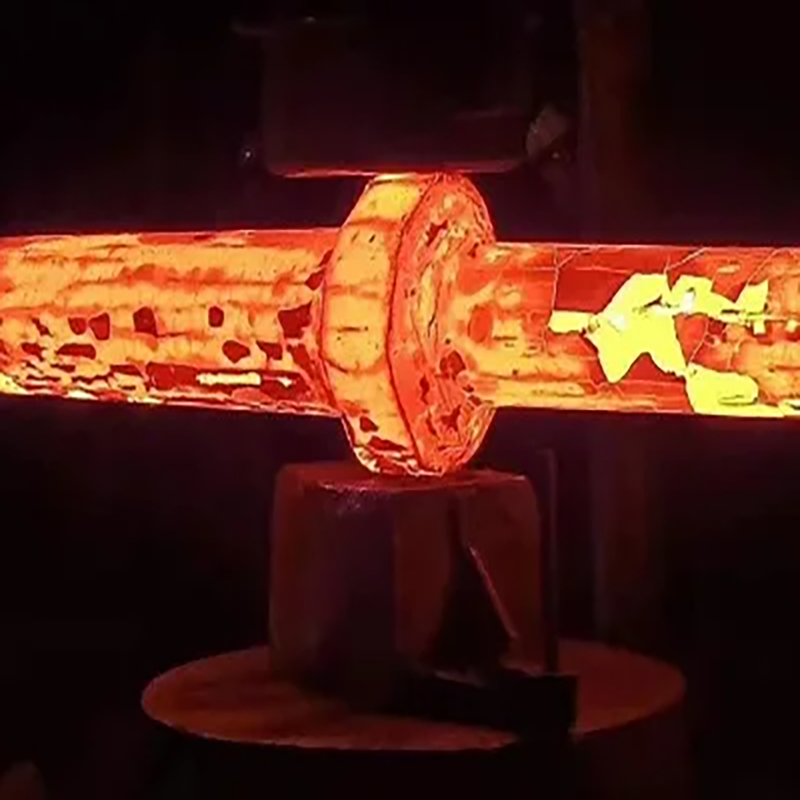

Introducing Pengxin’s Foundry Custom Services Precise Metal Aluminium Hot Forging Parts. This top-of-the-line product is a game-changer in the world of metal forging. Crafted with precision and expertise, these hot forging parts are designed to meet your specific needs and enhance the performance of your machinery

Made from high-quality aluminium, these parts are durable and long-lasting, making them the perfect choice for various industries. Whether you are in the automotive, aerospace, or manufacturing sector, Pengxin’s hot forging parts are guaranteed to deliver exceptional results

One of the key features of this product is its customize. Pengxin’s Foundry Custom Services allow you to tailor the design and specifications of the parts to suit your unique requirements. With a team of skilled engineers and technicians, Pengxin ensures that every detail is taken into consideration to create parts that are perfect for your application

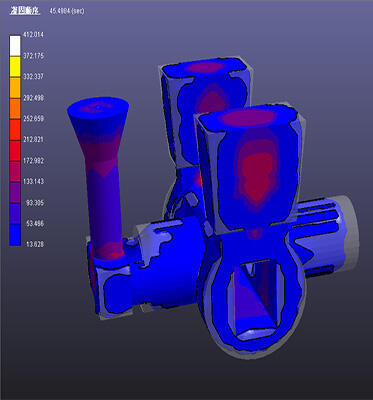

The hot forging process used in the production of these parts ensures that they are incredibly strong and can withstand high temperatures and heavy loads. This makes them ideal for use in demanding environments where reliability is crucial

In addition to their durability, Pengxin’s hot forging parts are also known for their precision. Every part is crafted with exceptional accuracy to ensure a perfect fit and seamless integration into your machinery. This results in improved performance and efficiency, ultimately leading to cost savings and increased productivity

Furthermore, Pengxin’s Foundry Custom Services offers competitive pricing and quick turnaround times, making it a cost-effective solution for businesses of all sizes. Whether you need a small batch of parts or a large order, Pengxin can accommodate your needs and deliver top-quality products in a timely manner

Pengxin’s Foundry Custom Services Precise Metal Aluminium Hot Forging Parts are the ideal choice for businesses looking for reliable, durable, and high-performance parts. With their customize, precision, and affordability, these parts are sure to exceed your expectations and help you achieve your goals. Upgrade your machinery today with Pengxin’s hot forging parts and experience the difference they can make in your operations

Material |

Aluminum, gray cast iron, ductile iron, stainless steel, copper, brass, galvanized etc |

||||||

Size |

Customized |

||||||

Surface treatment |

Powder coating, electroplating, oxide, anodization |

||||||

Technics |

Laser cut, bend, weld, stamp, casting, forging |

||||||

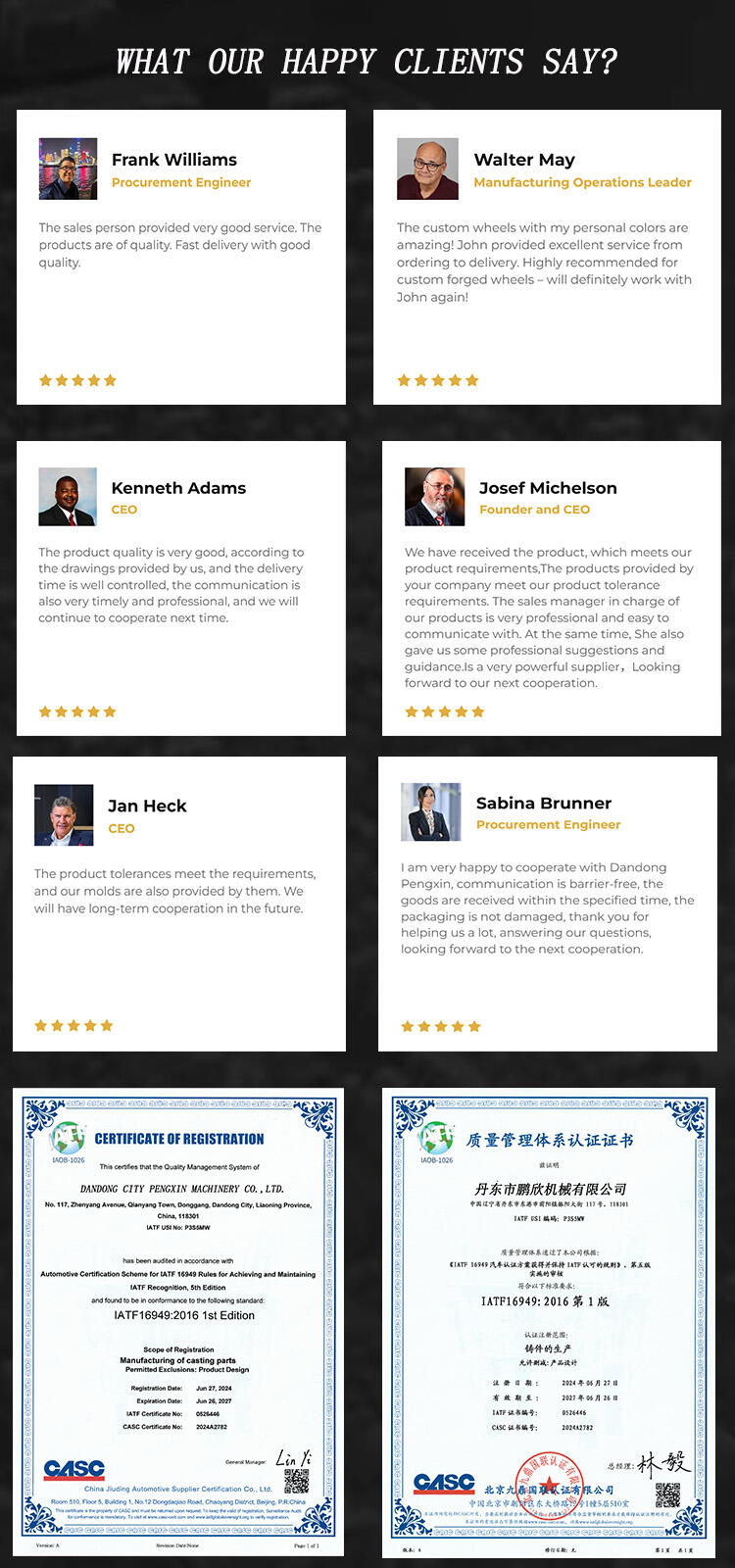

Certification |

ISO9001:2015 |

||||||

OEM |

Accept |

||||||

Drawing Format |

3D/CAD/Dwg/IGS/STEP |

||||||

Color |

Customized |

||||||

Application |

Appliance, Auto, Building, Capital equipment, Energy, Instrumentation, Medical device, Telecommunications |

||||||

Spanning 66,000 m² with 40,000 m² of workshops, it has $40M in assets and 330 employees, including 46 technical staff. Annual capacity reaches 100,000 tons

Pre-sales

On Sale

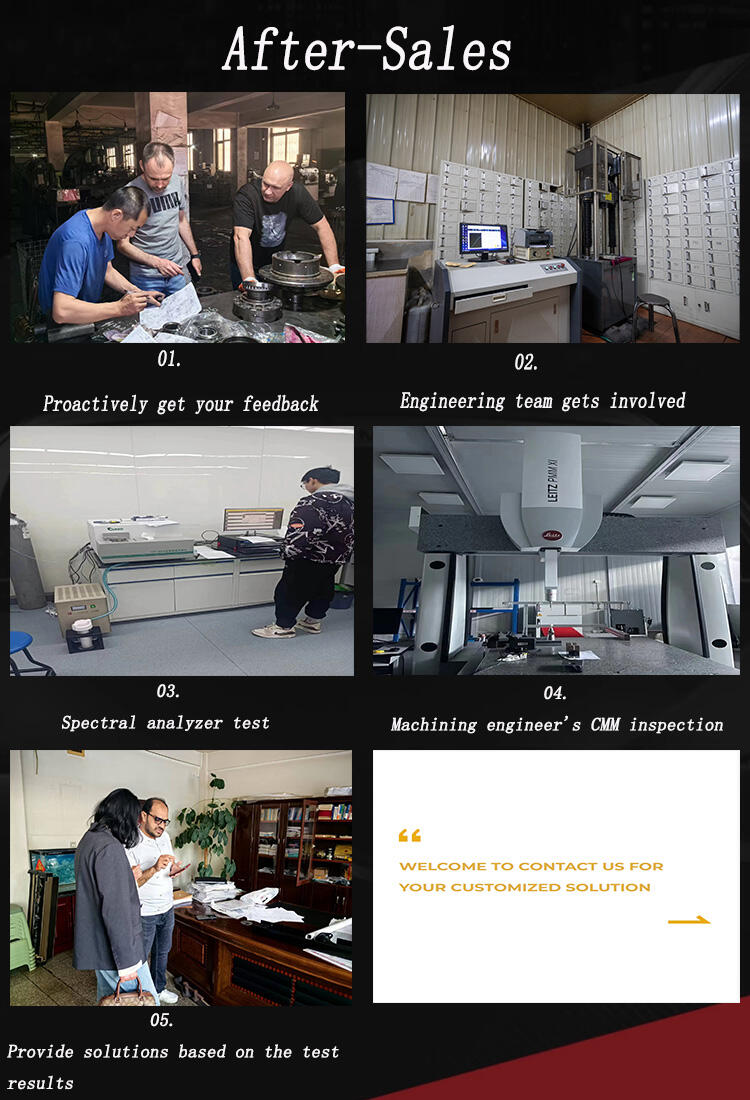

After-Sales

30,000 tons+Annual production capacity for Aluminum

80,000 tons+Annual production capacity for Steel

4000+Mold develop production

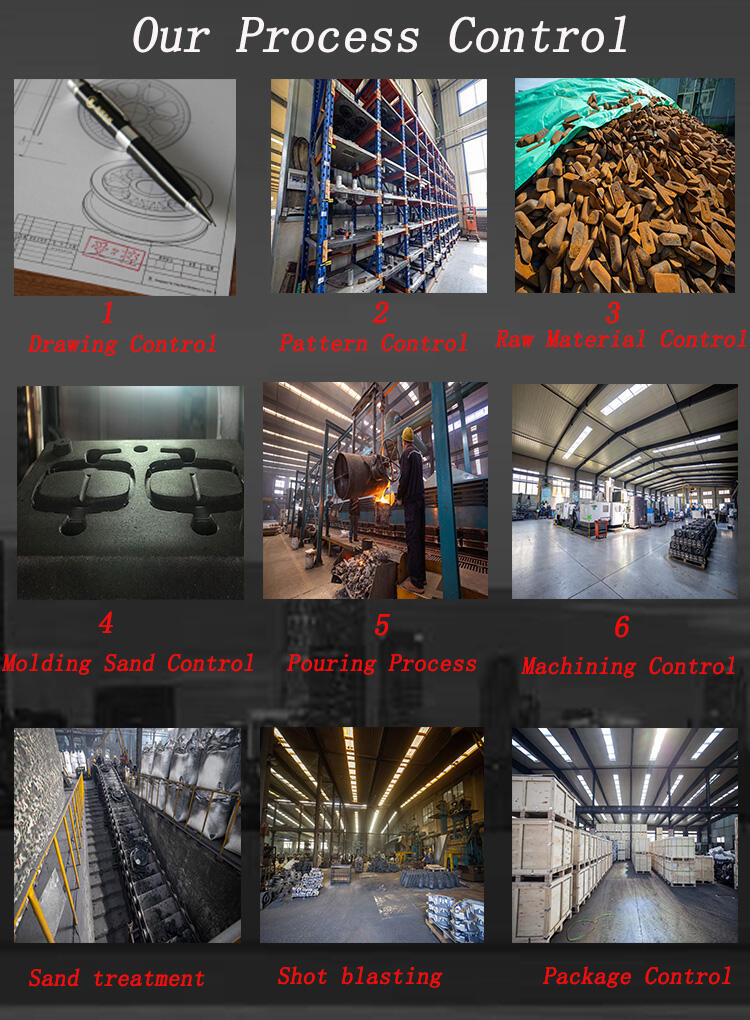

Quality Control

Pattern Control

Raw Material Control

Raw Casting & Machining Control