- Overview

- Recommended Products

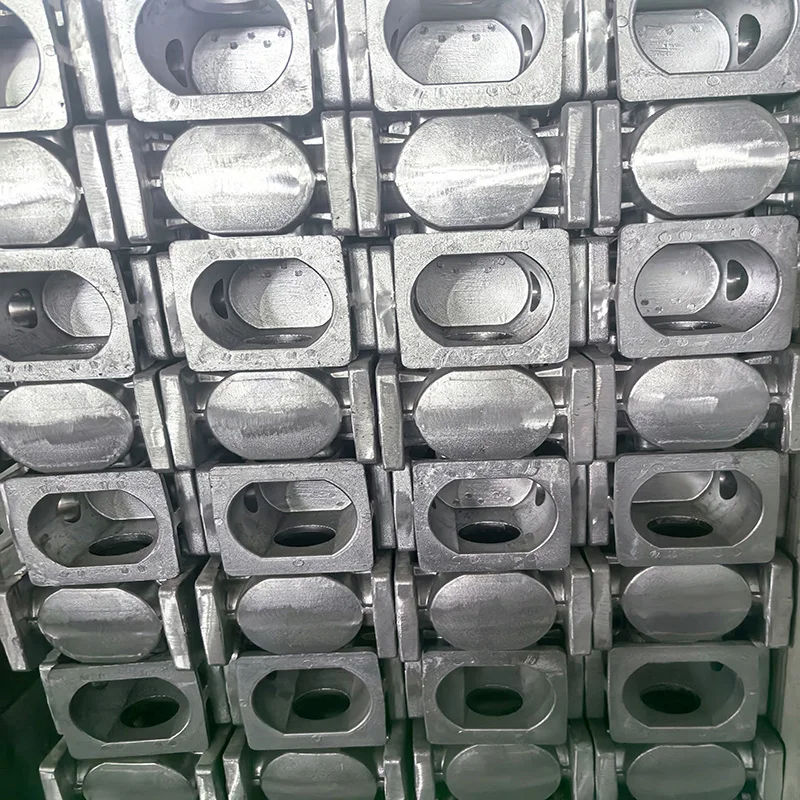

In industrial manufacturing where superior mechanical properties and exceptional dimensional consistency are paramount, High Quality Custom Gravity Die Casting Parts represent the optimal solution for high-volume production. Our specialized Metal Foundry Services leverage this advanced casting technology to deliver components with enhanced metallurgical integrity and outstanding surface quality, providing significant advantages over conventional casting methods.

Advanced Material Capabilities

Our gravity die casting services utilize premium aluminum and magnesium alloys specifically selected for their performance characteristics:

Aluminum Alloys: A356, A380, and ADC12 offering excellent strength-to-weight ratios

Magnesium Alloys: AZ91D and AM60B for ultra-lightweight applications

Specialty Alloys: Copper-based and zinc alloys for specific thermal/electrical requirements

These materials deliver superior mechanical properties including high tensile strength, excellent corrosion resistance, and good thermal conductivity.

Precision Manufacturing Process

The gravity die casting process employs reusable steel molds to create components with exceptional consistency:

-

Mold Preparation & Coating

High-grade tool steel molds manufactured to exacting specifications

Ceramic coatings applied for thermal management and release properties

Precise temperature control systems maintaining optimal mold conditions

-

Controlled Pouring & Solidification

Molten metal poured using automated ladling systems

Directional solidification techniques minimizing porosity

Optimized gating and riser systems ensuring complete filling

-

Secondary Processing

Heat treatment (T5, T6 temper) for enhanced mechanical properties

CNC machining maintaining tolerances within ±0.1mm

Surface finishing including powder coating, anodizing, and polishing

Key Technical Advantages

Dense Microstructure: Superior mechanical properties compared to sand casting

Excellent Surface Finish: Typically 3-5 μm Ra without secondary processing

High Dimensional Stability: Consistent repeatability across production runs

Thin-Wall Capability: Sections as thin as 3mm while maintaining structural integrity

Reduced Porosity: Enhanced pressure tightness for critical applications

Quality Assurance Protocol

Real-time process monitoring and data recording

Spectrochemical analysis for material verification

X-ray and ultrasonic testing for internal quality

Full dimensional inspection using CMM technology

Mechanical property testing to ASTM standards

Industry Applications

Our gravity die casting services serve demanding sectors including:

Automotive: Engine blocks, cylinder heads, transmission cases

Electrical Engineering: Motor housings, heat sinks, power distribution components

Industrial Equipment: Pump housings, hydraulic manifolds, machinery structural parts

Aerospace: Avionics enclosures, satellite components, auxiliary system parts

By integrating advanced process control with comprehensive metallurgical expertise, our Metal Foundry Services deliver gravity die cast components that meet the most demanding performance requirements while optimizing production efficiency and total cost of ownership for our clients.

Product Name |

casting parts/Die Casting Parts/sand casting part/aluminum die casting parts |

Casting Service |

Die Casting, Sand Casting, Gravity Casting, etc. |

Material |

QT200, 250,HT250, Aluminum ADC12, etc (Aupon your requirements.) |

Tooling Design |

We have own R&D team to make customized tooling, usually 7-15days can be ready. |

Standard |

China GB high precision standard. |

Surface Finish |

Mill Finishing, Anodizing, Powder coating, Wood grain, Polishing, Brushing, Electrophoresis. |

Drawing |

3D Drawing: .step / .stp, 2D Drawing: .dxf/ .dwg / .pdf |