- Overview

- Recommended Products

Technical Overview

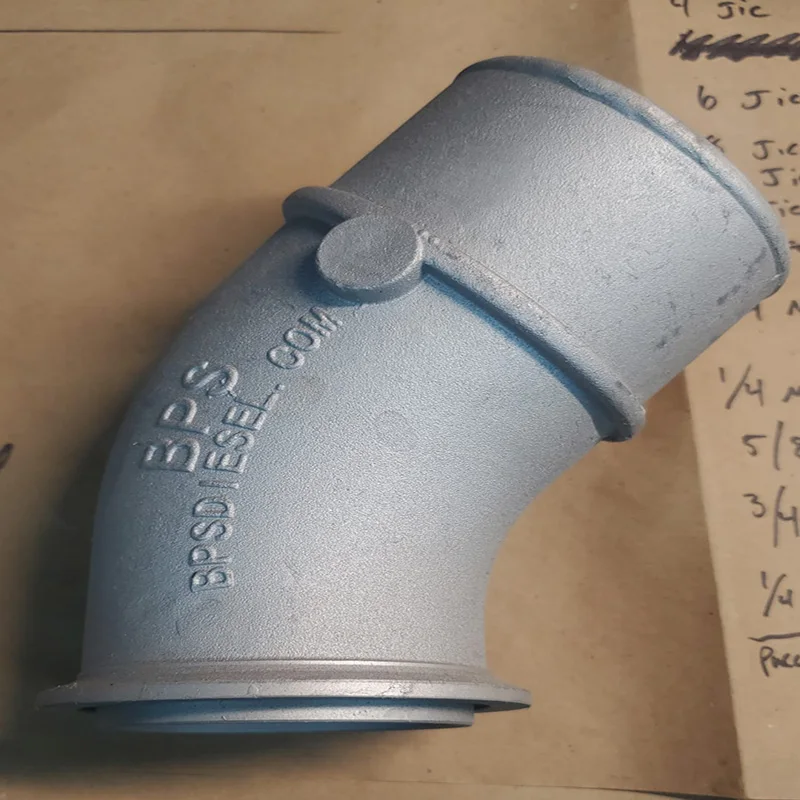

Aluminum alloy die casting and steel casting processes represent sophisticated manufacturing technologies for producing high-performance metal components. These methods enable the creation of complex geometries with excellent dimensional stability and mechanical properties, serving diverse industrial applications where reliability and precision are paramount.

Material Specifications

Aluminum Alloy Grades

A380: Excellent fluidity and mechanical properties

ADC12: Superior corrosion resistance and casting capability

A360: Outstanding pressure tightness and corrosion resistance

A413: Excellent pressure tightness and impact strength

Steel Casting Materials

Carbon steels: ASTM A216 WCB, WCC

Low-alloy steels: Enhanced mechanical properties

Stainless steels: 304, 316, CA15 for corrosion resistance

Heat-resistant steels: Suitable for high-temperature applications

Manufacturing Process Excellence

Aluminum Die Casting Process

Mold Design: Precision tooling with thermal management systems

Melting: Controlled atmosphere melting at 580-680°C

Injection: High-pressure injection (500-1500 bar)

Cooling: Optimized solidification control

Ejection: Automated part removal

Trimming: Flash removal and finishing

Steel Casting Methodology

Pattern making: Wood or metal patterns

Mold preparation: Sand molding processes

Pouring: Controlled temperature pouring

Solidification: Managed cooling cycles

Heat treatment: Normalizing, quenching, tempering

Surface treatment: Shot blasting, machining

Performance Characteristics

Aluminum Die Cast Parts

High strength-to-weight ratio

Excellent dimensional accuracy (±0.1mm)

Superior surface finish (Ra 1.6-3.2μm)

Good thermal and electrical conductivity

Thin-wall capability (0.5mm minimum)

Steel Cast Components

High mechanical strength and toughness

Excellent wear resistance

Good impact resistance

Superior high-temperature performance

Enhanced durability and lifespan

Quality Assurance Systems

Material certification and traceability

Dimensional verification with CMM

X-ray and ultrasonic testing

Mechanical property testing

Pressure testing for sealed components

Microstructure analysis

Industrial Applications

Automotive Industry

Engine blocks and transmission cases

Bracket components and housings

Structural reinforcement parts

Aerospace Sector

Aircraft structural components

Engine mounting parts

Control system elements

Industrial Machinery

Pump and valve bodies

Machinery frames and supports

Hydraulic system components

Electronics and Telecommunications

Heat sink components

Electronic enclosures

Communication device housings

Technical Advantages

High production efficiency and repeatability

Complex geometry capability

Reduced machining requirements

Cost-effective mass production

Consistent quality control

Material property optimization

These advanced casting technologies continue to evolve with integration of automation, real-time process monitoring, and quality control systems, meeting increasingly demanding requirements across global manufacturing sectors. The combination of aluminum die casting and steel casting processes provides comprehensive solutions for various industrial applications where precision, reliability, and performance are critical.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |