Prelucrare prin frezare CNC personalizată din aluminiu și oțel inoxidabil, servicii precise de strunjire și frezare, producție de serie

- Prezentare generală

- Produse recomandate

Producția modernă se bazează din ce în ce mai mult pe servicii precise de frezare și strunjire CNC pentru a produce componente în volume mari cu o acuratețe și repetabilitate excepțională. Capacitățile noastre specializate de producție în masă pentru piese din aluminiu și oțel inoxidabil oferă soluții rentabile industriei care necesită o calitate constantă pe întregul lot de producție.

Selecţia avansată a materialelor

Aliajele de aluminiu (6061, 7075, 5052) oferă un raport remarcabil între rezistență și greutate, conductivitate termică și electrică excelentă, precum și o rezistență naturală la coroziune. Aceste proprietăți fac din aluminiu un material ideal pentru aplicații în care reducerea greutății este esențială fără a compromite integritatea structurală. Prelucrabilitatea excelentă a materialului permite rate mai mari de producție și finisaje superficiale superioare.

Oțelurile inoxidabile (calitățile 304, 316, 416) oferă o rezistență mecanică superioară, o rezistență excepțională la coroziune și o stabilitate excelentă la temperatură. Oțelul inoxidabil își păstrează proprietățile în condiții dificile, fiind potrivit pentru aplicații medicale, marine și în procesarea chimică. Durabilitatea materialului asigură o performanță pe termen lung în condiții solicitante.

Capacități de Fabricație cu Precizie

Serviciile noastre de frezare CNC utilizează centre de prelucrare avansate cu 3, 4 și 5 axe, capabile să producă geometrii complexe cu toleranțe strânse. Prelucrarea pe mai multe axe permite procesarea completă a pieselor într-un singur montaj, reducând timpul de producție și minimizând erorile cumulative.

Operațiunile de strunjire CNC folosesc strunguri sofisticate cu scule active, permițând prelucrarea completă a pieselor de rotație într-o singură operație. Echipamentele noastre pot prelucra bare până la 65 mm diametru și piese până la 500 mm lungime, susținând atât cerințele de producție mică, cât și cele de mare scală.

Integrarea sistemelor automate de încărcare și a schimbătoarelor de palete asigură funcționarea continuă, maximizând eficiența producției pentru fabricarea în masă. Sistemele avansate de management al sculelor mențin o calitate constantă pe durata ciclurilor de producție prin monitorizarea uzurii sculelor și compensarea automată a abaterilor.

Avantaje ale producției în masă

Capacitate mare de volum cu calitate constantă pe toate loturile de producție

Costuri reduse pe piesă prin fluxuri de producție optimizate

Capacitatea de schimbare rapidă, minimizând timpul de staționare între rulările de producție

Control integrat al calității asigurând precizia dimensională în limitele ±0,005 inch

Volume de producție scalabile, de la sute la sute de mii de componente

Gama de Aplicabilitate Extinsă

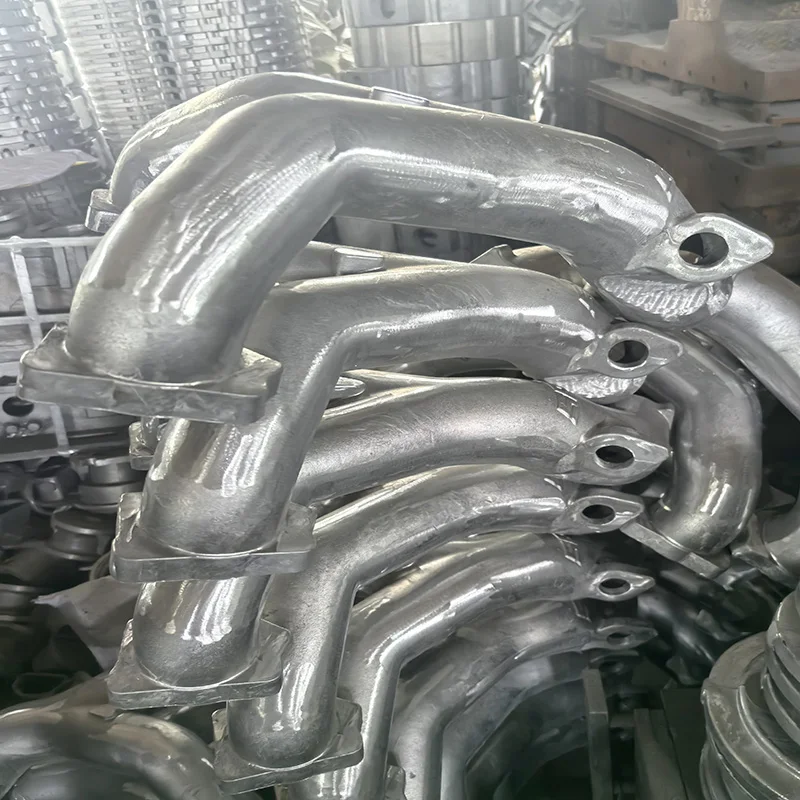

Automotive & Transport

Componente pentru motor și piese de transmisie

Elemente ale sistemului de alimentare și carcase pentru senzori

Suporturi structurale și componente de fixare

Aeronautică și Apărare

Elemente structurale pentru aeronave

Carcase pentru echipamente avionice și componente de montaj

Componente pentru sisteme de apărare și piese mecanice

Medical și asistență medicală

Componente ale instrumentelor chirurgicale

Carcase pentru dispozitive medicale și mecanisme interne

Piese pentru echipamente de diagnostic și componente ale sistemelor de imagistică

Industrial și consumer

Părți ale sistemelor de robotică și automatizare

Componente pentru manipularea fluidelor și corpuri de supapă

Carcasă pentru echipamente electronice de consum și ansambluri mecanice

Sistemele de asigurare a calității

Procesele noastre de producție în masă includ un management al calității cuprinzător:

Supravegherea proceselor statistice prin controlul parametrilor cheie de-a lungul producției

Inspecția primului articol și verificarea în cursul procesului utilizând tehnologia CMM

Certificarea materialelor și urmărirea acestora pe întreg lanțul de aprovizionare

Analiza finisajului superficial și testarea funcțională a caracteristicilor critice

Înregistrări de calitate documentate pentru fiecare lot de producție

Caracteristici de Eficiență a Producției

Linii de producție dedicate pentru fabricarea componentelor în volum mare

Principii de producție lean care minimizează risipa și optimizează fluxul de lucru

Sisteme avansate de planificare care asigură livrarea la timp pentru comenzile mari

Gestionarea stocurilor care susține cerințele de livrare just-in-time

Management de proiect dedicat care coordonează toate aspectele producției de masă

Material |

oțel, oțel inoxidabil, aluminiu, fier, oțel carbon, cupru, bronz, aliaj, etc. |

Grosime |

0.1mm la 12mm, după cererea dvs. |

Dimensiuni |

1) Conform desenelor clienților 2) Conform exemplarilor clienților |

Tratament de suprafață |

Anodizare, galvanizare, zinc, nicleu, cromare, îmbrăcăminte în pudră, vopseau, etc. |

Format desen |

DWG, DXF, STEP, STP, STL, AI, PDF, JPG, Schiță. |

Ambalare |

Punga de polietchilen + cutie de carton + cază de lemn/Paleta, conform cererii clientului |

Expediere |

1) Cu curier, cum ar fi DHL, TNT, Fedex, etc., de obicei 5-7 zile pentru a ajunge |

2) Cu avionul la aeroport, de obicei 3-4 zile pentru a ajunge |

|

3) Cu portul maritim, de obicei 15-30 de zile pentru a ajunge |

|

Termen de livrare |

depinde de cantități, de obicei aproximativ 20 de zile. |

Termen de plată |

T/T, Paypal, Trade Assurance |

Certificare |

Iso |

Serviciu de logo |

furnizate |

Aplicație |

utilizat în mod frecvent în construcții, industrie, industria automotive. |