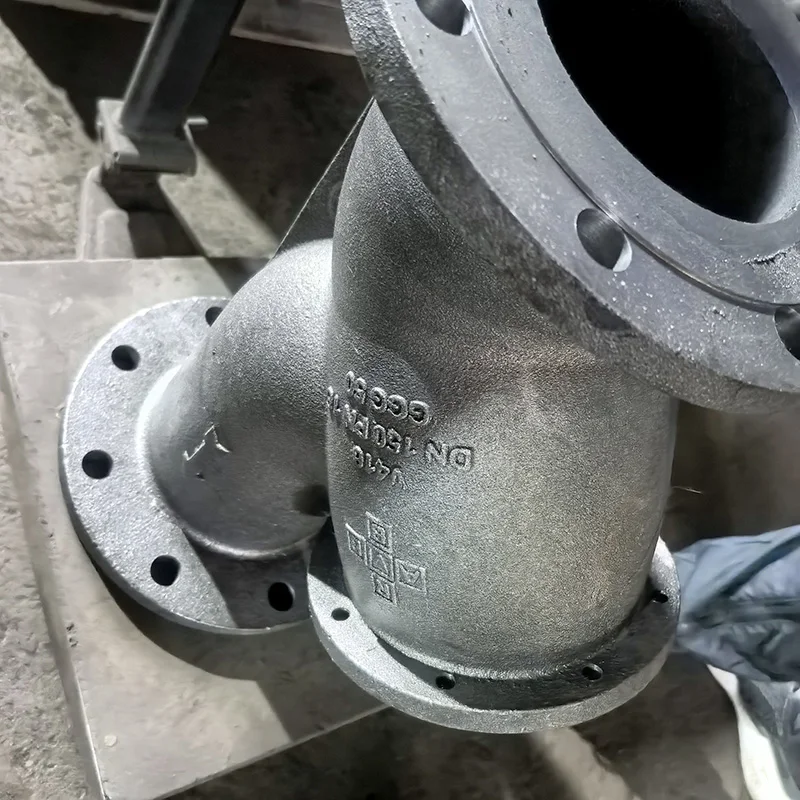

In industrial flow control systems, valve components manufactured through advanced shell mould resin sand casting represent a significant improvement in dimensional accuracy and surface quality. Our specialized foundry services focus on producing globe and gate valve parts using this sophisticated casting technology, delivering components that meet the stringent requirements of high-pressure and high-temperature applications. This manufacturing approach provides valve manufacturers with precision-cast parts that ensure reliable sealing performance and extended service life in demanding fluid handling environments.

Material Excellence and Performance Characteristics

We utilize premium carbon steel grades (WCB, WCC) and stainless steels (CF8, CF8M) specifically engineered for valve applications. Our WCB carbon steel components provide tensile strength of 485 MPa minimum with excellent pressure retention capabilities across temperature ranges from -29°C to 425°C. Stainless steel variants offer enhanced corrosion resistance with tensile strength of 515 MPa minimum, maintaining mechanical integrity in aggressive chemical environments. The shell mould resin sand casting process ensures superior surface finish (typically 3.2-6.3 μm Ra) and dimensional consistency, significantly improving sealing surface quality and reducing the need for extensive machining operations while maintaining pressure tightness up to 2500 PSI ratings.

Advanced Manufacturing Process

Our manufacturing integrates shell moulding technology with resin sand systems, creating moulds with exceptional dimensional stability (±0.0015 inches per inch) and surface definition. The process begins with metal pattern equipment heated to specific temperatures, which is then dumped with resin-coated sand to form precise mould halves. These mould halves are assembled into complete moulds capable of reproducing intricate valve geometries with minimal draft angles. Controlled pouring parameters and specialized gating systems ensure proper filling of thin sections and complex internal passages. Each valve part undergoes precision machining on CNC equipment, maintaining bore tolerances within IT8 standards and flange flatness within 0.001 inches per foot, ensuring perfect compatibility with mating components.

Comprehensive Valve Applications

Our shell mould resin sand cast valve parts serve critical functions across multiple industrial sectors including oil and gas pipelines (API 600/602 standards), power generation systems (ASTM A216 specifications), chemical processing plants, and water treatment facilities. The enhanced dimensional accuracy and surface quality make these components particularly suitable for severe service applications including steam systems, hydrocarbon processing, and corrosive media handling. Our manufacturing capabilities accommodate various pressure classes from 150 to 2500, with customized designs available for specific operational requirements including cryogenic service, elevated temperature applications, and corrosive media compatibility.

Partner with our foundry for shell mould resin sand cast globe and gate valve parts that combine manufacturing precision with application-specific engineering. Our technical expertise in both casting technology and valve component design ensures solutions that enhance valve performance, reduce manufacturing costs, and provide reliable service across diverse fluid control applications, supported by comprehensive quality certification and performance validation.