- Overview

- Recommended Products

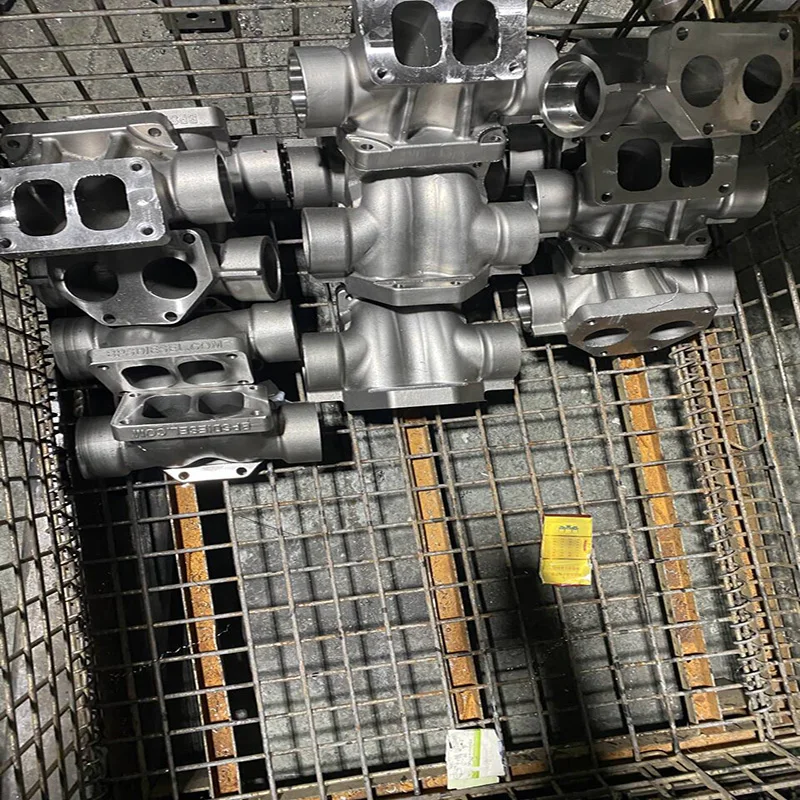

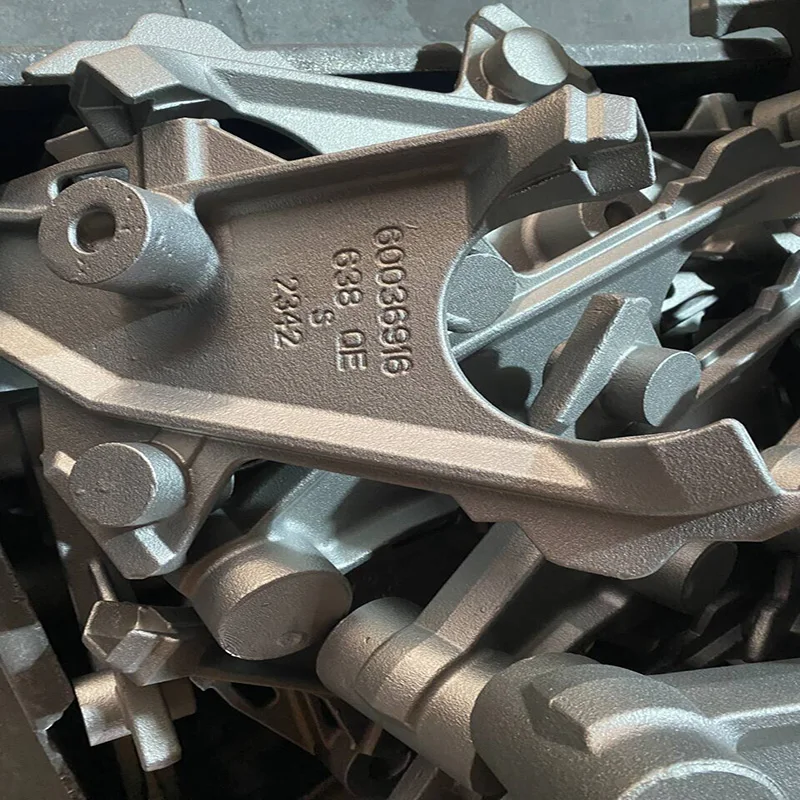

Investment casting, also known as the lost-wax process, represents one of the most precise and versatile metal forming techniques available for manufacturing complex 304 carbon steel components. This sophisticated manufacturing method enables production of near-net-shape parts with exceptional dimensional accuracy and surface finish, eliminating or significantly reducing the need for secondary machining operations while maintaining the superior mechanical properties of 304 carbon steel.

Material Properties and Performance Characteristics

304 carbon steel (also recognized as AISI 304 stainless steel) offers an optimal balance of mechanical strength and corrosion resistance, making it suitable for demanding applications across multiple industries. The material demonstrates:

Tensile strength: 505-860 MPa (depending on heat treatment condition)

Yield strength: 215-310 MPa at 0.2% offset

Elongation: 40-60% in 2 inches

Hardness: 70-90 HRB (Rockwell B scale)

Excellent corrosion resistance in various environments including mild atmospheric, freshwater, and food processing conditions

The chromium-nickel composition (18-20% Cr, 8-10.5% Ni) provides inherent corrosion resistance through the formation of a passive chromium oxide layer, while the austenitic microstructure ensures good toughness and formability.

Advanced Investment Casting Process

Our precision investment casting process involves multiple sophisticated stages:

Pattern Creation:

Injection molding of wax patterns using aluminum molds

Assembly of wax patterns into clusters for efficient production

Quality inspection of wax patterns for dimensional accuracy

Shell Building:

Multi-layer ceramic coating application using zircon-based primary coats

Successive dipping in refractory slurries with silica sand stuccoing

Controlled drying between each coating application

High-temperature firing (1000-1100°C) to achieve final mold strength

Metal Pouring and Finishing:

Precision melting of 304 carbon steel in induction furnaces

Controlled pouring temperature between 1500-1550°C

Knock-out, cut-off, and finishing operations

Heat treatment as required for specific mechanical properties

Technical Specifications and Quality Standards

Our investment casting services maintain rigorous quality parameters:

Dimensional tolerance: ±0.005 mm/mm for linear dimensions

Surface finish: Ra 1.6-3.2 μm achievable in as-cast condition

Minimum wall thickness: 1.5 mm for small to medium components

Casting weight range: 0.1 kg to 50 kg per piece

Compliance with international standards including ASTM A743 and ISO 4990

Quality Assurance and Testing Protocols

Every component undergoes comprehensive quality verification:

Chemical composition analysis using optical emission spectroscopy

Mechanical property testing including tensile and impact tests

Dimensional inspection using CMM and optical comparators

Surface and subsurface defect detection through liquid penetrant testing

Pressure testing for components requiring fluid containment

Industry Applications and Technical Advantages

304 carbon steel investment castings serve critical functions across multiple sectors:

Industrial Applications:

Valve bodies and pump components for fluid handling systems

Food processing equipment requiring corrosion resistance and cleanability

Architectural and construction hardware with aesthetic requirements

Medical and pharmaceutical equipment components

Marine and offshore hardware

Technical Advantages:

Complex geometry capability without additional assembly

Excellent surface finish reducing post-casting processing

Material consistency and metallurgical integrity

Design flexibility for optimized component performance

Cost-effectiveness for medium to high volume production

Our precision investment casting services for 304 carbon steel combine advanced manufacturing technology with rigorous quality control, delivering components that meet the most demanding application requirements while providing reliable long-term performance. The integration of modern foundry practices with comprehensive testing ensures consistent quality across production batches, making investment casting the preferred manufacturing method for complex 304 carbon steel components where precision, reliability, and performance are paramount.

Our Services |

CNC Precision Milling Machining,CNC Precision Turning Machining, Rapid Prototyping Plastic Injection Mould Metal Stamping, Die Casting, Silicone And Rubber Mould, Aluminum Extrusion, Mould Fabrication,etc |

Material |

Aluminum Alloy:5052/6061/6063/7075 etc Brass Alloy: 3602/2604/h59/h62/etc Stainless Steel Alloy: 303/304/316/412/etc Steel Alloy: Carbon/Die Steel/etc Other Special Materials: Lucite/Nylon/Bakelite/etc Plastic, Wood, Silicone, Rubber,Or as per the customers’ requirements |

Surface Treatment |

Anodizing, Sandblasting, Painting, Powder coating, Electroplating, Silk Printing, Brushing, Polishing, Laser Engraving... |

Drawing Format |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl,etc |

Service Project |

To provide project design, production and technical service, mould development and fabrication, etc |

Testing Machine |

Digital Height Gauge, caliper, Three Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

Quality Assurance |

ISO9001:2015 Certified TUV |

Packing |

Foam, Carton, Wooden boxes, or as per the customer’s requirements |

Deliver |

DHL, FEDEX, UPS, TNT, EMS, SF Or according to customers′ requirement |