- סקירה

- מוצרים מומלצים

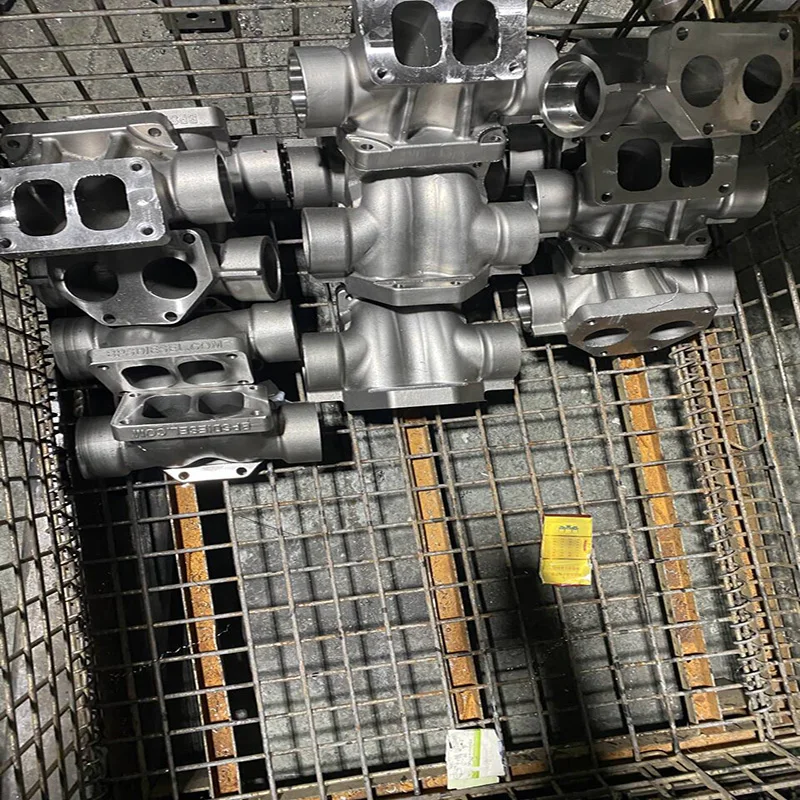

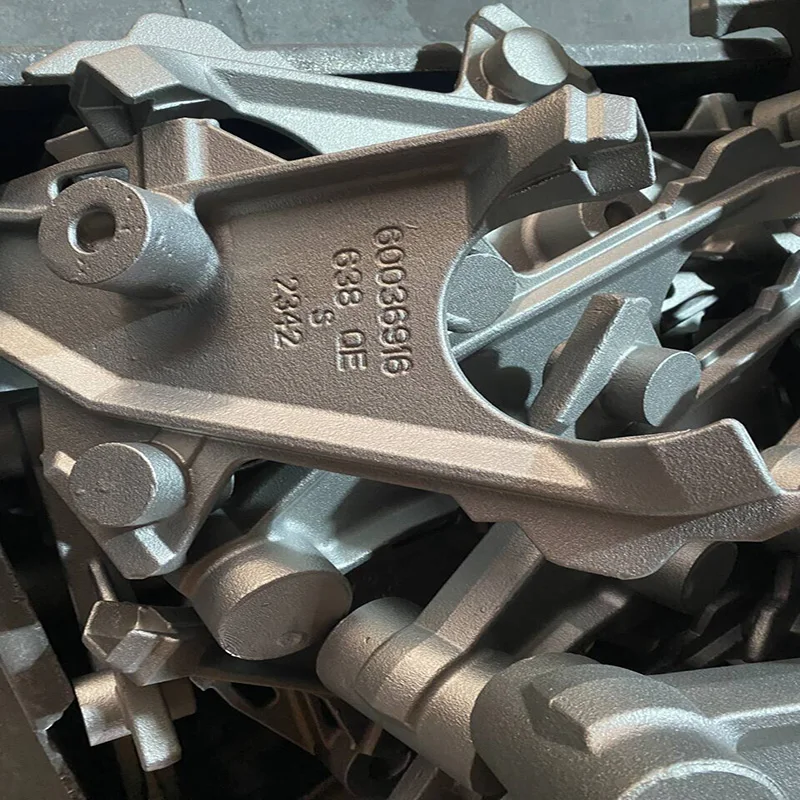

יציקת השקעה, הידועה גם כתהליך שעווה אבודה, מייצגת אחת מטכניקות עיצוב המתכת המדויקות והרב-תכליתיות ביותר הקיימות לייצור רכיבים מורכבים מפלדת פחמן 304. שיטת ייצור מתוחכמת זו מאפשרת ייצור של חלקים בעלי צורה כמעט סופית בדיוק מימדי וגימור פני שטח יוצאי דופן, תוך ביטול או הפחתה משמעותית של הצורך בפעולות עיבוד שבבי משניות תוך שמירה על התכונות המכניות המעולות של פלדת פחמן 304.

תכונות החומר והמאפיינים הביצועיים

פלדת פחמן 304 (הידועה גם כפלדת אל-חלד AISI 304) מציעה שילוב אופטימלי של חוזק מכני ועמידות בפני שחיקה, מה שהופך אותה למתאימה לשימושים דרמטיים בתחומים רבים. החומר מפגין:

חוזק מתיחה: 505–860 MPa (תלוי בתנאי עיבוד חום)

חוזק תסיסה: 215–310 MPa ב-0.2% היסט

הארכה: 40–60% בשני אינץ'

קשיות: 70–90 HRB (סולם רוקוול B)

עמידות מעולה בפני שחיקה בסביבות שונות, כולל אטמוספרה עדינה, מים מתוקים ותנאי עיבוד מזון

הרכב הכרום-ניקל (18–20% Cr, 8–10.5% Ni) מספק עמידות בפני שחיקה על ידי יצירת שכבת חומצת כרום פסיבית, בעוד המיקרו-מבנה האוסטניטי מבטיח עמידות וצמיגות טובה.

תהליך יציקת הון מתקדם

תהליך הזרקה מדויק שלנו כולל מספר שלבים מתקדמים:

יצירת תבנית:

הזרקת תבניות שעווה באמצעות תבניות אלומיניום

הרכבת דגמי שעווה לקבוצות לייצור יעיל

בדיקת איכות של תבניות שמן מבחינת דיוק ממדי

בניית קליפה:

החלה מרובה שכבות של ציפוי קרמיקה באמצעות שכבות ראשוניות מבוססות זירקון

טבילה עוקבת בתערובות אבקה משופכות עם סטוקו של חול סיליקה

יבוש מבוקר בין כל החלה של שכבת קרמיקה

אפייה בטמפרטורה גבוהה (1000-1100°C) להשגת חוזק תבנית סופי

ריסוס מתכת וסיום:

התכה מדויקת של פלדת כربון 304 בתוך תנורי השראה

שליטה בטמפרטורת ריסוס בין 1500-1550°C

הסרת התבנית, חיתוך ופעולות סיום

טיפול حراري לפי דרישה לשם קבלת תכונות מכניות מסוימות

מפרט טכני וסטנדרטים לאיכות

שירותי הזרקת ההשקעה שלנו שומרים על פרמטרי איכות קפדניים:

סובלנות ממדית: ±0.005 מ"מ/מ"מ לממדים ליניאריים

גימור משטח: Ra 1.6-3.2 מיקרון ניתן להשגה במצב יצוק

עובי דופן מינימלי: 1.5 מ"מ לרכיבים קטנים ובינוניים

טווח משקל יציקה: 0.1 ק"ג עד 50 ק"ג לכל חלק

תאמה לתקנים בינלאומיים כולל ASTM A743 ו-ISO 4990

פרוטוקולים לאבטחת איכות ולבדיקות

כל רכיב עובר אימות איכות מקיף:

ניתוח הרכב הכימי באמצעות ספקטרוסקופיה אופטית של פליטה

בדיקת תכונות מכניות כולל מבחני משיכה ומבחני תקלה

בדיקת ממדים באמצעות מכונת מדידה קואורדינטיבית (CMM) ושוווני אור

זיהוי פגמים במשטח ובשכבות תחתונות באמצעות בדיקת חדירת נוזל

בדיקת לחץ לרכיבים הדורשים אטימה של נוזלים

יישומי התעשייה והיתרונות הטכניים

יציקות סטאל 304 משמשות תפקידי מפתח במספר תחומים:

יישומים תעשייתיים:

גופי שסתומים ורכיבי משאבה למערכות טיפול בנוזלים

ציוד לעיבוד מזון הדורש עמידות בתהום ויכולת ניקוי

ハードוור אדריכלי ובנאי עם דרישות אסתטיות

רכיבים לציוד רפואי ופ harmaceuti

ハードוור ימי וחצי ימי

יתרונות טכנולוגיים:

יכולת ייצור של גאומטריה מורכבת ללא הרכבה נוספת

גימור משטח מעולה שמפחית עיבוד לאחר הזרקה

עקביות של החומר ושלמות מתלורגית

גמישות בעיצוב לצורך ביצועים מיטמיים של הרכיב

יעילות עלות להפקה בינונית עד גבוהה

שירותי הזרקת השקעה המדויקת שלנו לפלדת פחמן 304 משלבים טכנולוגיית ייצור מתקדמת עם בקרת איכות מחמירה, ומייצרים רכיבים העונים על דרישות היישום הקשות ביותר תוך כדי שנותנים ביצועים אמינים לאורך זמן. שילוב של פרקטיקות מודרניות של מסגר עם בדיקות מקיפות מבטיח איכות עקיבה בין סדרות ייצור, מה שהופך את ייצור הזרקת השקעה לשיטת הייצור המועדפת לרכיבי פלדת פחמן 304 מורכבים בהם דיוק, אמינות וביצועים הם בעלי חשיבות עליונה.

השירותים שלנו |

חיתוך מדויק CNC, מסתובב מדויק CNC פרוטוטיפינג מהיר תבנית הזרקת פלסטיק דכיסת מתכת, יציקת מolds מold סיליקון וgom, הרכבה של אלומיניום, ייצור מolds, וכו' |

חומר |

אלומיניום סגסוגת: 5052/6061/6063/7075 וכו' סיג סגסוגת: 3602/2604/h59/h62/וכו' פלדה נקיה סגסוגת: 303/304/316/412/וכו' סגסוגת פלדה: פחמן/פלדת מודעות/וכו' חומרים חומרים מיוחדים: לוקסיט/נילון/בקליט/וכו' פלסטלסטיק, עץ, סיליקון, גומי, או לפי דרישות הלקוח |

טיפול שטח |

אנודה, שפיכת חול, ציור, כיסוי אבקה, חשמל-גלאי,蠶ילק דפוס, תספורת, מברשת, פולישינג, חיתוך לייזר... |

פורמט ציור |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl, וכו' |

פרויקט שירות |

להספק שירות של תכנון פרויקט, ייצור וטכנולוגי, פיתוח ומניית מolds, וכו' |

מבחן מכונה |

מד גובה דיגיטלי, קליפר, מכונת מדידה של שלושת הקואורדינטות, מכונת הקרנה, מדד חריפות, מדד קשיחות וכן הלאה |

הבטחת איכות |

ISO9001: 2015 TUV מוסמך |

אריזה |

קופסאות קופסת עץ, או לפי דרישות הלקוח |

להעביר |

DHL, FEDEX, UPS, TNT, EMS, SF או לפי דרישות הלקוחות |