- Overview

- Recommended Products

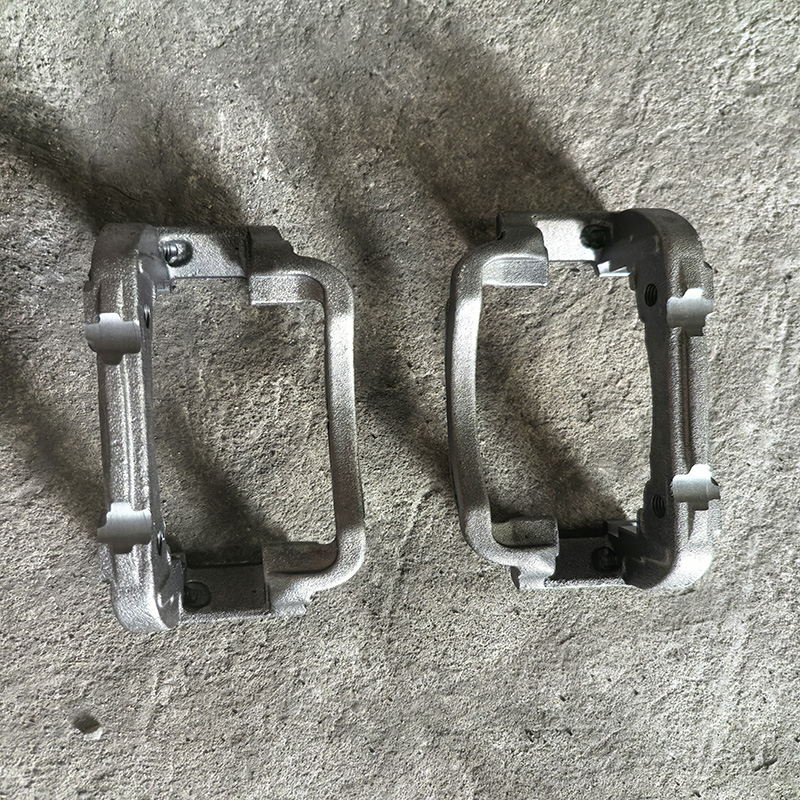

Universal brake calipers represent critical safety components in automotive braking systems, requiring exceptional structural integrity and thermal management capabilities. Our high-quality casting services specialize in producing reliable brake calipers that meet stringent automotive standards while delivering consistent performance under demanding operating conditions.

Material Selection and Performance Characteristics

We utilize premium aluminum-silicon alloys, primarily A356-T6 and A357-T6, specifically engineered for brake caliper applications. These materials provide an optimal balance of lightweight properties and mechanical strength, with documented performance characteristics including:

Tensile strength: 234-262 MPa (A356-T6)

Yield strength: 164-193 MPa

Elongation: 3-5%

Low thermal expansion coefficient: 21.5 μm/m°C

High thermal conductivity: 120-150 W/mK

The aluminum-silicon composition (7% Si, 0.3% Mg) ensures excellent corrosion resistance while maintaining dimensional stability across temperature variations from -40°C to 250°C.

Advanced Manufacturing Process

Our integrated production methodology combines sophisticated casting techniques with precision machining:

Low-Pressure Die Casting: Utilizes controlled metal filling at 0.5-1.0 bar pressure, ensuring dense microstructure with porosity below 1%

Heat Treatment: T6 tempering process involving solution treatment at 540°C for 8 hours, quenching, and artificial aging at 160°C for 4-6 hours

-

CNC Machining: 5-axis machining centers maintain critical tolerances:

Mounting surface flatness: ≤0.05mm

Piston bore diameter: H7 tolerance

Surface finish: Ra ≤ 1.6μm on sliding surfaces

Quality Assurance and Testing

Each brake caliper undergoes comprehensive validation:

100% pressure testing at 200 bar for 30 seconds

X-ray inspection for internal defect detection

Dimensional verification using CMM with ±0.01mm accuracy

Metallurgical analysis ensuring proper grain structure (ASTM E112)

Corrosion resistance testing per SAE J2334

Performance Advantages

Our casting technology delivers significant benefits:

Weight reduction up to 40% compared to iron counterparts

Improved heat dissipation reducing brake fade

Enhanced stiffness-to-weight ratio

Consistent wall thickness (3-8mm) throughout complex geometries

Superior fatigue resistance exceeding 1 million cycles at 70 MPa stress

Application Versatility

Our universal brake calipers accommodate diverse vehicle platforms:

Passenger cars and light commercial vehicles

Performance and sports vehicles

Electric and hybrid vehicles

Aftermarket and replacement applications

The integration of advanced low-pressure die casting with precision machining ensures reliable brake calipers that meet OEM specifications while providing optimal braking performance and extended service life. Our commitment to quality management systems, including IATF 16949 certification, guarantees consistent component performance and customer satisfaction across all automotive applications.

Our Services |

CNC Precision Milling Machining,CNC Precision Turning Machining, Rapid Prototyping Plastic Injection Mould Metal Stamping, Die Casting, Silicone And Rubber Mould, Aluminum Extrusion, Mould Fabrication,etc |

Material |

Aluminum Alloy:5052/6061/6063/7075 etc Brass Alloy: 3602/2604/h59/h62/etc Stainless Steel Alloy: 303/304/316/412/etc Steel Alloy: Carbon/Die Steel/etc Other Special Materials: Lucite/Nylon/Bakelite/etc Plastic, Wood, Silicone, Rubber,Or as per the customers’ requirements |

Surface Treatment |

Anodizing, Sandblasting, Painting, Powder coating, Electroplating, Silk Printing, Brushing, Polishing, Laser Engraving... |

Drawing Format |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl,etc |

Service Project |

To provide project design, production and technical service, mould development and fabrication, etc |

Testing Machine |

Digital Height Gauge, caliper, Three Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

Quality Assurance |

ISO9001:2015 Certified TUV |

Packing |

Foam, Carton, Wooden boxes, or as per the customer’s requirements |

Deliver |

DHL, FEDEX, UPS, TNT, EMS, SF Or according to customers′ requirement |