- Overview

- Recommended Products

Investment Casting Excellence

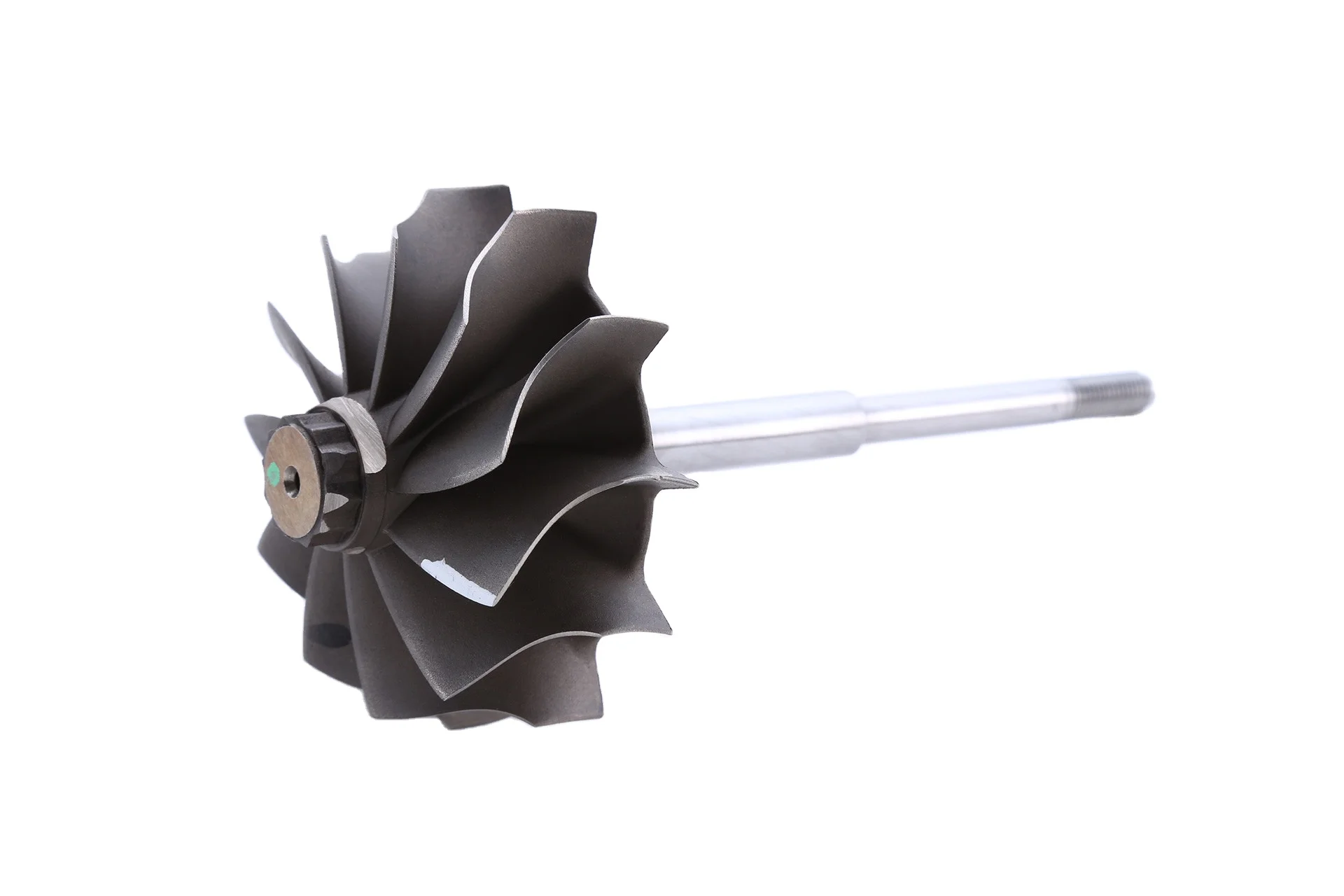

Our ceramic shell investment casting process produces turbine wheels with exceptional dimensional accuracy and surface integrity:

Directional solidification techniques creating controlled grain structures for enhanced high-temperature performance

Vacuum melting and pouring ensuring minimal gas porosity and superior metallurgical quality

Precise dimensional control maintaining blade profiles and critical tolerances within ±0.13 mm

Complex geometry capability producing intricate blade designs with aerodynamic efficiency

Machining and Finishing

Post-casting operations ensure components meet precise specifications:

CNC turning and milling of shaft journals and bearing surfaces to tolerances within ±0.005 mm

Precision grinding of critical diameters and sealing surfaces

Dynamic balancing achieving balance levels better than G2.5 at operating speeds

Surface enhancement including shot peening for improved fatigue resistance

Enhanced Performance Characteristics

Components manufactured through our specialized processes deliver:

Exceptional high-temperature strength maintaining structural integrity at continuous operating temperatures exceeding 850°C

Superior creep resistance minimizing deformation under sustained high-temperature loading

Excellent thermal fatigue properties withstanding repeated thermal cycling without crack initiation

Optimal oxidation resistance maintaining surface stability in high-velocity exhaust environments

Enhanced durability providing extended service life under severe operating conditions

Comprehensive Quality Assurance

Our manufacturing processes incorporate rigorous quality protocols:

Radiographic inspection detecting internal defects and verifying structural integrity

Fluorescent penetrant testing identifying surface discontinuities and potential crack initiation sites

Material certification verifying chemical composition and mechanical properties

Dimensional validation using coordinate measuring machines for critical features

Performance testing including overspeed validation and burst testing

Technical Application Expertise

Our turbocharger components serve demanding applications across multiple sectors:

Automotive Performance

High-performance passenger vehicles requiring rapid spool response and durability

Racing applications demanding maximum reliability under extreme conditions

Commercial vehicle systems providing enhanced efficiency and power density

Aerospace and Marine

Aircraft auxiliary power units requiring certified reliability and performance

Marine propulsion systems operating in corrosive saltwater environments

Industrial power generation supporting continuous operation in demanding conditions

Engineering Partnership Approach

We provide comprehensive technical support services:

Design for manufacturability analysis optimizing component geometry for casting and machining

Material selection guidance based on specific operating conditions and performance requirements

Prototype development accelerating product validation and testing cycles

Production scaling from low-volume specialty applications to high-volume manufacturing

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |