- Översikt

- Rekommenderade Produkter

Inom det krävande området optisk mätteknik utgör precisions-CNC-fräsade spindlar kritiska komponenter där exceptionell noggrannhet möter avancerad tillverkningsteknologi. Dessa specialtillverkade spindlar, tillverkade med strama toleranser på 0,005 mm, säkerställer stabiliteten och precisionen som krävs för högpresterande optiska system inom vetenskapliga, industriella och rymdtillämpningar.

Fördjupat materialval

Tillverkningen av spindlar till optiska instrument använder specialmaterial konstruerade för exceptionell stabilitet och prestanda:

Högkvalitativa rostfria stål (304, 316, 17-4PH) som ger excellent korrosionsbeständighet och dimensionsstabilitet

Verktygsstål (D2, A2) som erbjuder överlägsen slitstyrka och hårdhetsbevarande

Titanlegeringar (Grade 5, Ti-6Al-4V) som ger högt styrka-till-vikt-förhållande för flyg- och rymdapplikationer

Speciallegeringar formulerade för minimal termisk expansion och vibrationsdämpningsegenskaper

Dessa material genomgår noggrann certifiering för att säkerställa konsekventa mekaniska egenskaper och prestandakarakteristika lämpliga för precisionsoptiska applikationer -1.

Noggrannhetsteknik och prestation

CNC-slipade spindlar för optiska instrument levererar exceptionella prestandaegenskaper:

Extrem dimensionell noggrannhet med toleranser inom 0,005 mm (5 μm) för kritiska funktioner

Utmärkta ytytor som uppnår ytjämnhet på Ra 0,2–0,8 μm genom precisionslipning

Exceptionell rotationsnoggrannhet med excentricitet vanligtvis mindre än 0,001 mm vid monteringsytan

Strikt dynamisk balansering som uppnår balansnivåer på G2,5 eller bättre vid driftshastigheter upp till 20 000 varv per minut

Förbättrad styvhet och vibrationsdämpning som säkerställer stabilitet vid precisionsoptiska mätningar -4-7

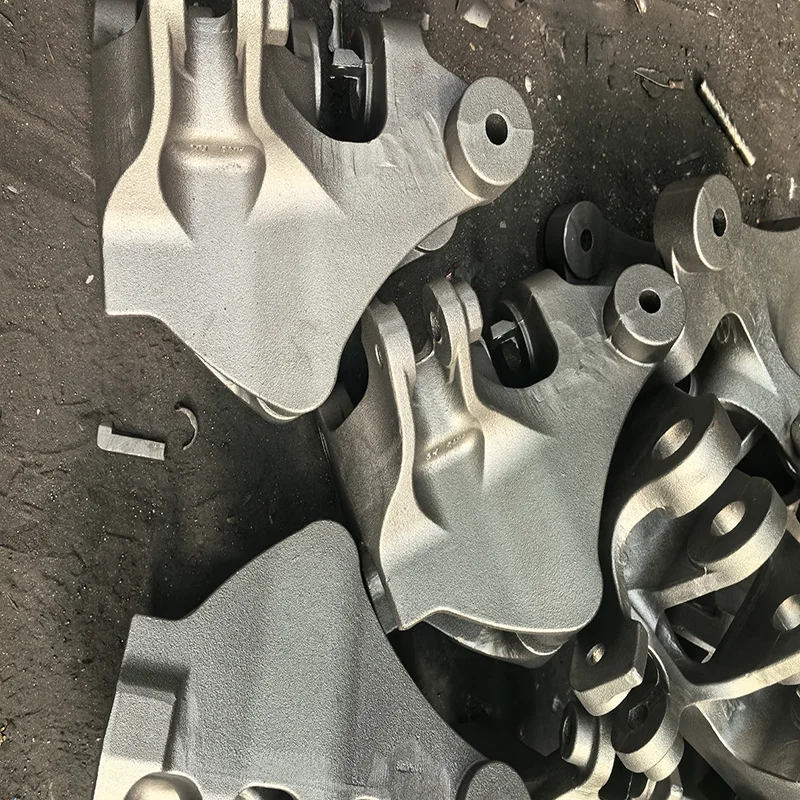

Avancerade tillverkningsprocesser

Tillverkningen av dessa högprecisionsaxlar integrerar flera avancerade tillverkningsteknologier:

Precisionssvarvning och slipning

CNC-svarv- och fräsoperationer som håller toleranser inom ±0,005 mm för kritiska dimensioner

Flervals slipningsprocesser som uppnår överlägsen ytfinish och geometrisk noggrannhet

Precisionsboring och honing av lagerytor för att säkerställa optimal passning och prestanda

Avancerade värmebehandlingsprocesser som stabiliserar komponenter och förbättrar slitstyrka

Kvalitetssäkring och metrologi

Omfattande kontroll med koordinatmätningsmaskiner (CMM) där alla kritiska dimensioner verifieras

Ytanalys med profilometrar för att säkerställa efterlevnad av krav för optiska tillämpningar

Dynamisk balansverifiering vid driftshastigheter för att minimera vibrationer

Strikt materialcertifiering som bekräftar sammansättning och mekaniska egenskaper -2-5

Specialanpassat användningsområde

Precisionsspindlar tillverkade enligt dessa stränga standarder används inom många optiska tillämpningar:

Vetenskapliga och forskningsinstrument

Mikroskopsystem som kräver ultrastabil positionering och hantering av prov

Spektroskopiutrustning som kräver exakt optisk justering och repeterbarhet

Interferometriska system där minimal vibration och maximal stabilitet är avgörande

Industriella optiska system

Linstillverknings- och testutrustning som kräver exakt positionering och rörelsestyrning

Automatiserade optiska inspektionssystem (AOI) för tillverkning av halvledare och elektronik

Laserbearbetningsutrustning där precision i strålstyrning och fokusering är avgörande

Luft- och rymdfarts-optik

Satellitbildsystem som kräver pålitlighet i extrema miljöer

Målsättnings- och övervakningssystem som kräver hög noggrannhet under driftsförhållanden

Navigationsinstrument för luft- och rymdfart där precision och pålitlighet är av yttersta vikt -9

Teknisk excellens och anpassning

Vårt ingenjörsangreppssätt ger omfattande lösningar skräddarsydda för specifika optiska tillämpningar:

Utformning för tillverkningsanalys som optimerar spindelkonstruktioner för både prestanda och produktionseffektivitet

Materialvalsguidning baserad på specifika applikationskrav och miljöförhållanden

Prototyputveckling som påskyndar validerings- och testcykler

Produktionsskalning från enskilda prototyper till mellanvolymtillverkningsomgångar

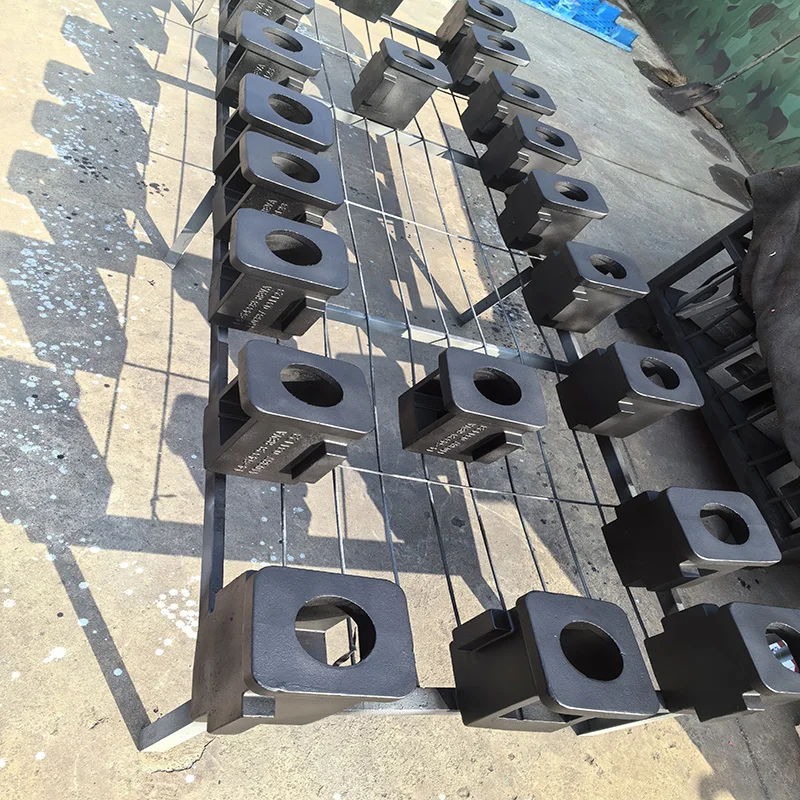

Kvalitetssäkringsdokumentation

Varje spindel inkluderar fullständig dokumentation:

Materialintyg som verifierar sammansättning och mekaniska egenskaper

Dimensionella inspectionsrapporter som bekräftar överensstämmelse med angivna toleranser

Prestandatestdata inklusive balansrapporter och excentricitetsmätningar

Spårbarhetsregister som säkerställer en fullständig produktionshistorik för kritiska applikationer

Material |

stål, rostfritt stål, aluminium, järn, kolstål, koppar, mässing, legering, etc. |

Tjocklek |

0,1mm till 12mm, enligt din begäran |

Storlekar |

1) Enligt kundritningar 2) Enligt kundprov |

Ytbehandling |

Anodering, galvanisering, zink, nikel, kromplåt, pulvermålning, måleri, etc. |

Ritningsformat |

DWG, DXF, STEP, STP, STL, AI, PDF, JPG, Draft. |

Förpackning |

Polyväska+Kartonspackning+Träkasse/Pall, enligt kundens önskemål |

Frakt |

1) Genom kurir, som DHL, TNT, Fedex, etc, vanligtvis 5-7 dagar att anlända |

2) Genom luft till flygplats, vanligtvis 3-4 dagar att anlända |

|

3) Genom hamn, vanligtvis 15-30 dagar att anlända |

|

Leveranstid |

beroende på mängderna, vanligtvis runt 20 dagar. |

Betalningsvillkor |

T/T, Paypal, Handelsgaranti |

Certifiering |

ISO |

Logotjänst |

tillhandahållen |

Ansökan |

används bredvid på byggnad, industri, bilindustri. |