- বিবরণ

- প্রস্তাবিত পণ্য

অপটিক্যাল যন্ত্রপাতির কঠোর ক্ষেত্রে, প্রিসিশন সিএনসি গ্রাউন্ড স্পিন্ডলগুলি এমন গুরুত্বপূর্ণ উপাদান যেখানে অসাধারণ নির্ভুলতা উন্নত উৎপাদন প্রযুক্তির সাথে মিলিত হয়। এই বিশেষ স্পিন্ডলগুলি 0.005 মিমি কঠোর সহনশীলতার সাথে তৈরি করা হয়, যা বিজ্ঞান, শিল্প এবং মহাকাশ প্রযুক্তির মতো ক্ষেত্রে উচ্চ কার্যকারিতা সম্পন্ন অপটিক্যাল সিস্টেমগুলির জন্য প্রয়োজনীয় স্থিতিশীলতা এবং নির্ভুলতা নিশ্চিত করে।

উন্নত উপকরণ নির্বাচন

অপটিক্যাল যন্ত্রের স্পিন্ডল উৎপাদনে ব্যবহৃত বিশেষ উপকরণগুলি অসাধারণ স্থিতিশীলতা এবং কার্যকারিতার জন্য প্রকৌশলী করা হয়:

উচ্চমানের স্টেইনলেস ইস্পাত (304, 316, 17-4PH) যা দুর্দান্ত ক্ষয় প্রতিরোধ এবং মাত্রার স্থিতিশীলতা প্রদান করে

টুল স্টিল (D2, A2) যা চরম ক্ষয় প্রতিরোধ এবং কঠোরতা ধরে রাখার বৈশিষ্ট্য প্রদান করে

টাইটানিয়াম খাদ (গ্রেড 5, Ti-6Al-4V) যা এয়ারোস্পেস অ্যাপ্লিকেশনের জন্য ওজনের তুলনায় উচ্চ শক্তি প্রদান করে

ন্যূনতম তাপীয় প্রসারণ এবং কম্পন হ্রাসের বৈশিষ্ট্যের জন্য বিশেষভাবে তৈরি খাদ

এই উপকরণগুলি নির্ভুল আলোকীয় অ্যাপ্লিকেশনের জন্য উপযুক্ত মাত্রাত্মক বৈশিষ্ট্য এবং কর্মদক্ষতা নিশ্চিত করতে কঠোর শংসাপত্র প্রক্রিয়ার মধ্য দিয়ে যায় -1.

যথার্থ প্রকৌশল ও পারফরম্যান্স

আলোকীয় যন্ত্রের জন্য CNC গ্রাউন্ড স্পিন্ডেলগুলি অসাধারণ কর্মদক্ষতা বৈশিষ্ট্য প্রদান করে:

গুরুত্বপূর্ণ বৈশিষ্ট্যগুলির জন্য 0.005 মিমি (5μm) এর মধ্যে সহনশীলতা সহ চরম মাত্রার নির্ভুলতা

নির্ভুল গ্রাইন্ডিং প্রক্রিয়ার মাধ্যমে Ra 0.2-0.8μm এর মধ্যে ক্ষুদ্রতর পৃষ্ঠের মান অর্জন

মাউন্টিং ইন্টারফেসে সাধারণত 0.001 মিমি এর নিচে রানআউট সহ অসাধারণ ঘূর্ণন নির্ভুলতা

গতিশীল ভারসাম্য বজায় রাখার জন্য কঠোর প্রক্রিয়া যা 20,000 RPM পর্যন্ত অপারেশনাল গতিতে G2.5 বা তার বেশি ভারসাম্য স্তর অর্জন করে

দৃঢ়তা এবং কম্পন নিয়ন্ত্রণ আরও উন্নত করে নির্ভুল আলোকিক পরিমাপের সময় স্থিতিশীলতা নিশ্চিত করা হয় -4-7

উন্নত উৎপাদন পদ্ধতি

এই উচ্চ-নির্ভুলতার স্পিন্ডলগুলির উৎপাদনে একাধিক উন্নত উৎপাদন প্রযুক্তি একীভূত করা হয়:

নির্ভুল যন্ত্র কাজ এবং ঘষা

CNC টার্নিং এবং মিলিং অপারেশন যা গুরুত্বপূর্ণ মাত্রাগুলির জন্য ±0.005mm মধ্যে সহনশীলতা বজায় রাখে

বহু-অক্ষ ঘষার প্রক্রিয়া যা উন্নত পৃষ্ঠের মান এবং জ্যামিতিক নির্ভুলতা অর্জন করে

বিয়ারিং পৃষ্ঠের নির্ভুল বোরিং এবং হোনিং যা অনুকূল ফিট এবং কর্মক্ষমতা নিশ্চিত করে

ন্নত তাপ চিকিত্সা প্রক্রিয়া যা উপাদানগুলির স্থিতিশীলতা বজায় রাখে এবং ক্ষয় প্রতিরোধ ক্ষমতা বৃদ্ধি করে

গুণগত নিশ্চয়তা এবং পরিমাপ বিজ্ঞান

সমন্বিত পরিদর্শন যা সমন্বিত পরিমাপ যন্ত্র (CMM) ব্যবহার করে এবং সমস্ত গুরুত্বপূর্ণ মাত্রার যাচাই করে

অপটিক্যাল অ্যাপ্লিকেশনের প্রয়োজনীয়তা মেনে চলা নিশ্চিত করতে প্রোফিলোমিটার ব্যবহার করে পৃষ্ঠের ফিনিশের বিশ্লেষণ

কম্পন কমানোর জন্য কার্যকরী গতিতে গতিশীল ভারসাম্য যাচাইকরণ

উপাদানের গঠন এবং যান্ত্রিক বৈশিষ্ট্য নিশ্চিত করে কঠোর উপাদান সার্টিফিকেশন -2-5

বিশেষ অ্যাপ্লিকেশন পরিসর

এই কঠোর মানগুলির অধীনে উৎপাদিত নির্ভুল স্পিন্ডেলগুলি বিভিন্ন অপটিক্যাল অ্যাপ্লিকেশনে ব্যবহৃত হয়:

বৈজ্ঞানিক এবং গবেষণা যন্ত্র

মাইক্রোস্কোপি সিস্টেম যেখানে অত্যন্ত স্থিতিশীল নমুনা স্থাপন এবং নিয়ন্ত্রণের প্রয়োজন

স্পেক্ট্রোস্কোপি সরঞ্জাম যেখানে সঠিক অপটিক্যাল সারিবদ্ধকরণ এবং পুনরাবৃত্তিমূলকতা প্রয়োজন

ইন্টারফেরোমেট্রিক সিস্টেম যেখানে কমপক্ষে কম্পন এবং সর্বোচ্চ স্থিতিশীলতা অপরিহার্য

শিল্প অপটিক্যাল সিস্টেম

লেন্স উত্পাদন এবং পরীক্ষার সরঞ্জাম যেখানে সূক্ষ্ম অবস্থান নির্ধারণ এবং গতি নিয়ন্ত্রণের প্রয়োজন

অটোমেটেড অপটিক্যাল ইনস্পেকশন (AOI) সিস্টেম যা অর্ধপরিবাহী এবং ইলেকট্রনিক্স উৎপাদনে ব্যবহৃত হয়

লেজার প্রক্রিয়াকরণ সরঞ্জাম যেখানে বীম স্টিয়ারিং এবং ফোকাসিংয়ের সূক্ষ্মতা অপরিহার্য

এয়ারোস্পেস এবং ডিফেন্স অপটিক্স

উপগ্রহ ইমেজিং সিস্টেম যা চরম পরিবেশে নির্ভরযোগ্যতা প্রয়োজন

লক্ষ্য নির্ধারণ এবং নজরদারি সিস্টেম যেগুলি কার্যকরী অবস্থার অধীনে শুদ্ধতা চায়

এয়ারোস্পেস নেভিগেশন যন্ত্র যেখানে সূক্ষ্মতা এবং নির্ভরযোগ্যতা সর্বোচ্চ গুরুত্বপূর্ণ -9

প্রযুক্তিগত দক্ষতা এবং কাস্টমাইজেশন

আমাদের প্রকৌশলী পদ্ধতি নির্দিষ্ট অপটিক্যাল অ্যাপ্লিকেশনের জন্য অভিযোজিত ব্যাপক সমাধান প্রদান করে:

উৎপাদনযোগ্যতার জন্য ডিজাইন, যা স্পিন্ডল ডিজাইনগুলিকে কার্যকারিতা এবং উৎপাদন দক্ষতা উভয় ক্ষেত্রেই অনুকূলিত করে

নির্দিষ্ট অ্যাপ্লিকেশনের প্রয়োজনীয়তা এবং পরিবেশগত শর্তের ভিত্তিতে উপাদান নির্বাচনের নির্দেশনা

প্রোটোটাইপ উন্নয়ন যা বৈধতা এবং পরীক্ষার চক্রগুলি ত্বরান্বিত করে

একক প্রোটোটাইপ থেকে মাঝারি আয়তনের উৎপাদন পর্যন্ত উৎপাদন স্কেলিং

গুণগত নিশ্চয়তা ডকুমেন্টেশন

প্রতিটি স্পিন্ডেলের সম্পূর্ণ ডকুমেন্টেশন অন্তর্ভুক্ত থাকে:

উপাদানের প্রত্যয়ন যা গঠন এবং যান্ত্রিক বৈশিষ্ট্য যাচাই করে

মাত্রার পরিদর্শন প্রতিবেদন যা নির্দিষ্ট সহনশীলতার সাথে সম্মতি নিশ্চিত করে

কর্মক্ষমতা পরীক্ষার তথ্য যাতে ব্যালেন্স প্রতিবেদন এবং রানআউট পরিমাপ অন্তর্ভুক্ত

ট্রেসেবিলিটি রেকর্ড যা গুরুত্বপূর্ণ অ্যাপ্লিকেশনের জন্য সম্পূর্ণ উৎপাদন ইতিহাস নিশ্চিত করে

উপাদান |

আয়রন, স্টেইনলেস স্টিল, অ্যালুমিনিয়াম, ফার্নি স্টিল, কপার, ব্রাস, এলয়েড ইত্যাদি |

পুরুত্ব |

০.১মিমি থেকে ১২মিমি, আপনার অনুরোধ অনুযায়ী |

আকার |

১) গ্রাহকদের ড্রাইংয়ানুসারে ২) গ্রাহকদের নমুনায় অনুযায়ী |

পৃষ্ঠ চিকিত্সা |

অ্যানোডিং, গ্যালভানাইজড, জিঙ্ক, নিকেল, ক্রোম প্লেটিং, পাউডার কোটিং, পেইন্টিং ইত্যাদি |

অঙ্কন বিন্যাস |

ডিডব্লিউজি, ডিক্সএফ, স্টেপ, স্টিপি, এসটিএল, এআই, পিডিএফ, জেপিজে, ড্রাফট। |

প্যাকিং |

পলিব্যাগ+কার্টন বক্স+উডেন কেস/প্যালেট, গ্রাহকের অনুরোধ অনুযায়ী |

প্রেরণ |

১) কুরিয়ের মাধ্যমে, যেমন DHL, TNT, Fedex ইত্যাদি, সাধারণত ৫-৭ দিনে পৌঁছায় |

২) বিমান বন্দরে বিমানের মাধ্যমে, সাধারণত ৩-৪ দিনে পৌঁছায় |

|

৩) সমুদ্র বন্দরের মাধ্যমে, সাধারণত ১৫-৩০ দিনে পৌঁছায় |

|

ডেলিভারি সময় |

পরিমাণের উপর নির্ভরশীল, সাধারণত ২০ দিনের আসরে। |

পেমেন্ট শর্ত |

T/T, Paypal, ট্রেড এসুরেন্স |

সার্টিফিকেশন |

ISO |

লোগো সার্ভিস |

প্রদান করেছেন |

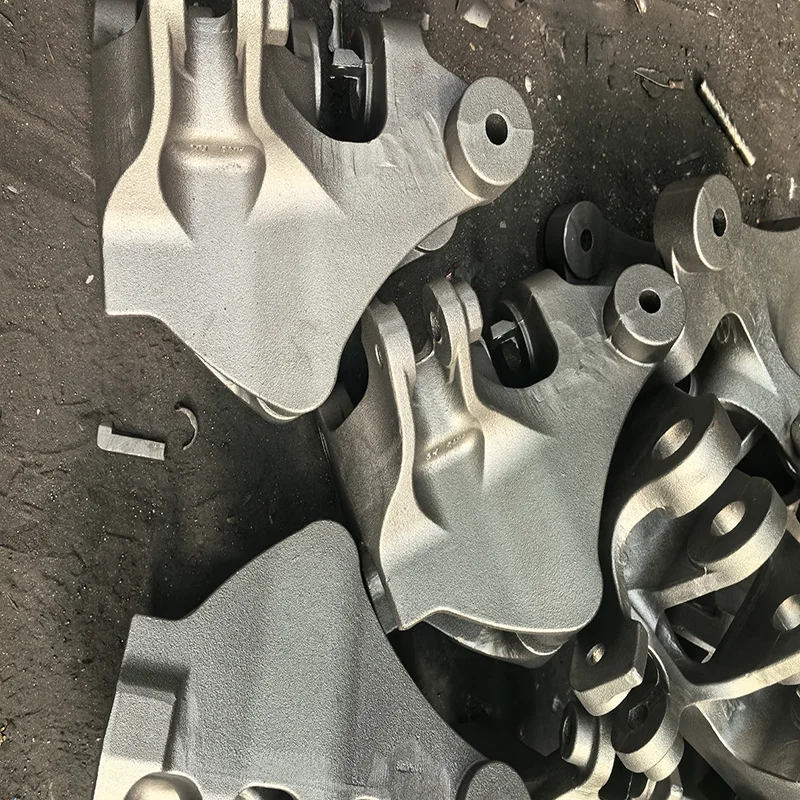

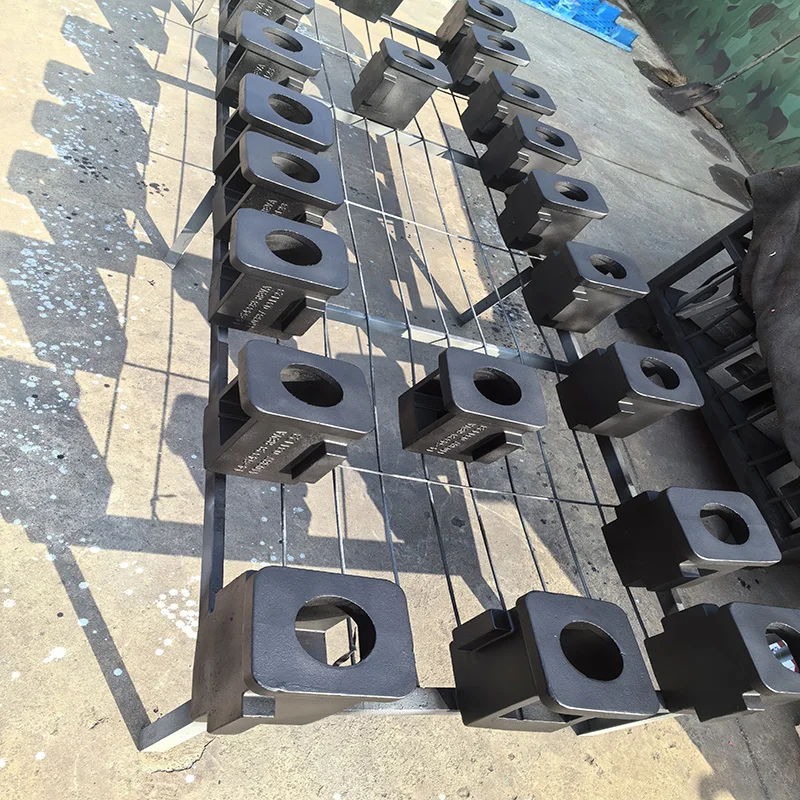

আবেদন |

বিশালভাবে কনস্ট্রাকশন, শিল্প, ওটোমোবাইল শিল্পে ব্যবহৃত হয়। |