- Overview

- Recommended Products

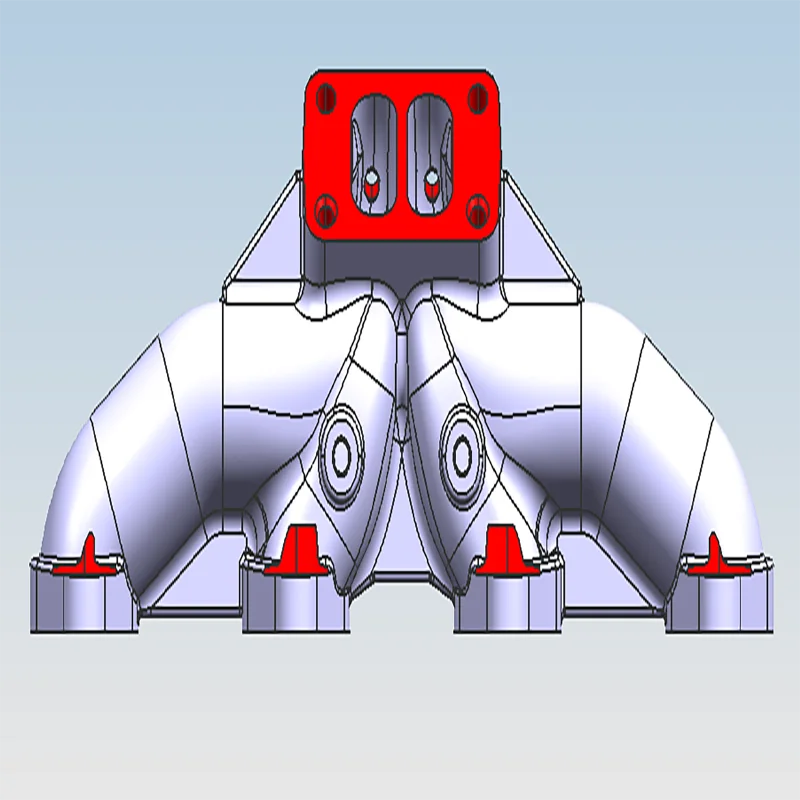

The automotive exhaust manifold plays a critical role in engine efficiency and emission control, serving as the first component in the exhaust system. Its design and material selection directly impact vehicle performance, fuel economy, and compliance with environmental regulations. Modern manifolds must withstand extreme thermal cycling, corrosive exhaust gases, and mechanical vibrations while maintaining optimal exhaust flow characteristics.

Material Selection for Extreme Conditions

Advanced materials are essential for meeting these demanding requirements:

Austenitic Stainless Steels (304, 321): Excellent oxidation resistance and good formability

Ferritic Stainless Steels (409, 441): Good thermal fatigue resistance and cost-effectiveness

Silicon Molybdenum Ductile Iron: Superior thermal conductivity and fatigue strength

Inconel Alloys (625, 718): Exceptional high-temperature capability for performance applications

Advanced Manufacturing Processes

Modern exhaust manifolds are produced using sophisticated methods:

-

Casting Technologies

Shell molding for complex runner geometries

Investment casting for thin-wall sections

Computer-controlled solidification analysis

-

Fabrication Methods

Hydroformed tubular sections for optimized flow

Laser-welded stampings for weight reduction

Modular assembly techniques for serviceability

Performance Characteristics

Thermal Management: Withstanding continuous operation at 800-950°C

Structural Integrity: Maintaining dimensional stability under thermal cycling

Flow Efficiency: Minimizing back pressure through computational fluid dynamics optimization

Durability: Achieving service life exceeding 150,000 miles through proper material selection

Design Innovations

Equal-Length Runner Designs: Improving scavenging efficiency

Integrated Turbocharger Mounts: Reducing thermal losses

Air Gap Insulation: Maintaining exhaust gas temperatures for catalytic converter efficiency

Vibration Isolation: Incorporating flexible coupling elements

Quality Validation

Thermal cycle testing per SAE J2749

Pressure decay leak testing

Metallographic analysis of microstructural stability

Vibration fatigue testing simulating engine conditions

Applications

Passenger Vehicle Powertrains

Commercial Diesel Engines

High-Performance Motorsports

Hybrid and Range-Extender Applications

The evolution of exhaust manifold design continues to focus on weight reduction, improved thermal efficiency, and enhanced durability. Through advanced materials and manufacturing techniques, modern manifolds contribute significantly to meeting both performance expectations and emission standards in contemporary automotive engineering.

Why are we called OEM experts in Exhaust Manifolds |

We develop over 100 different types of exhaust manifolds every year |

||||||

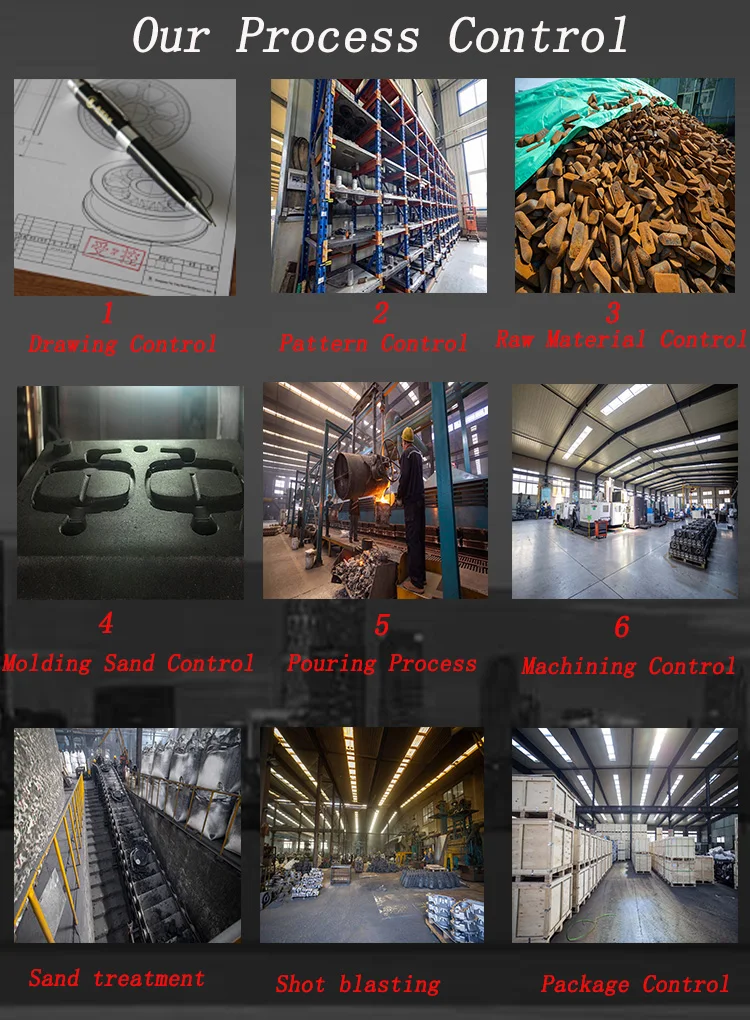

Dandong Pengxin Production Process for Exhaust Manifold |

Drawing Preparation: The Foundation of Precision,3D Scanning & Drafting: Our professional engineers use advanced scanners to convert samples into 2D/3D drawings (7–10 days). |

||||||

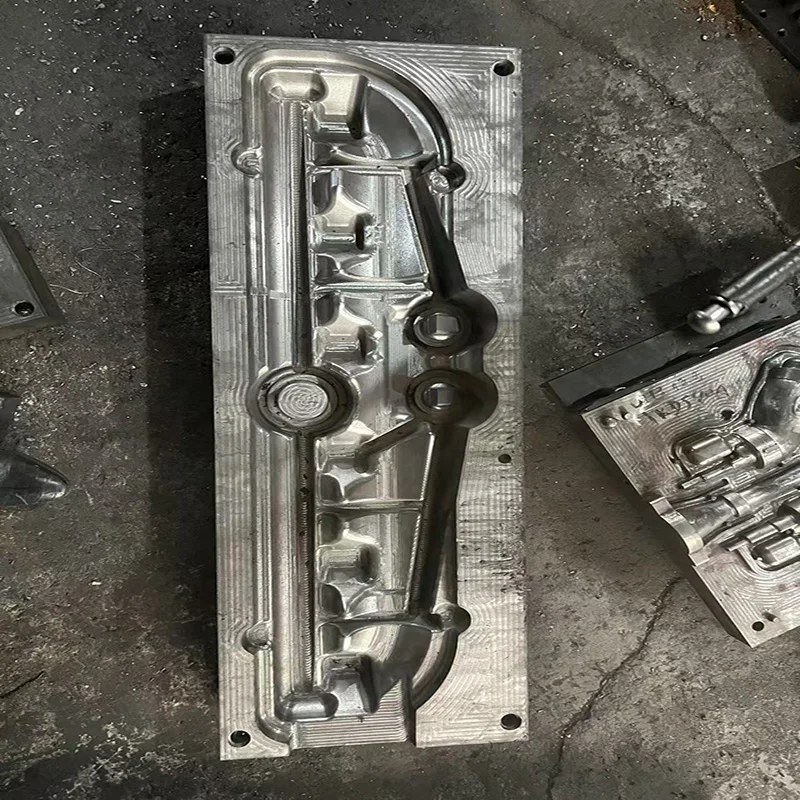

Pattern & Sample Development: Where Time Invested Pays Off |

Complexity: Exhaust manifolds often require 3–5 sets of metal patterns (vs. 1 set for simpler castings).Lead Time: 35–40 days for multi-cavity patterns; 25–30 days for simpler designs. |

||||||

Initial Orders & Batch Production: Scaling Responsibly |

Machine Allocation: One manifold order may occupy 2–3 molding machines. Our 16-machine facility prioritizes urgent orders and collaborates with partner foundries for auxiliary cores. |

||||||

How Investors Can Mitigate Delays |

Allocate 8–12 weeks for pattern/sample development. Compressing this risks quality failures. First batches take 20–30% longer due to process fine-tuning. Post-approval, lead times stabilize. |

||||||

Pre-sales

On Sale

After-Sales

results→Welcome to contact us for your customized solution.

How did Dandong Pengxin Become a Top Manufacturer of Exhaust Manifold

Process designs derive from engineering drawings

3D scanners

Metal Mold for Exhuast Manifold,Coated sand casting

Metal Mold for Exhaust Manifold,Sand Casting

Exhaust Manifold Core Box

Shell Molding Machine

Coated sand casting

Molding Machines

R&D

Production Capacity

Pattern Control

Abaqus,Moldflow and Moldex 3D, simulate feeding system, reduce casting defects and improve efficiency.

Raw Material Control

Machining Control