- Overview

- Recommended Products

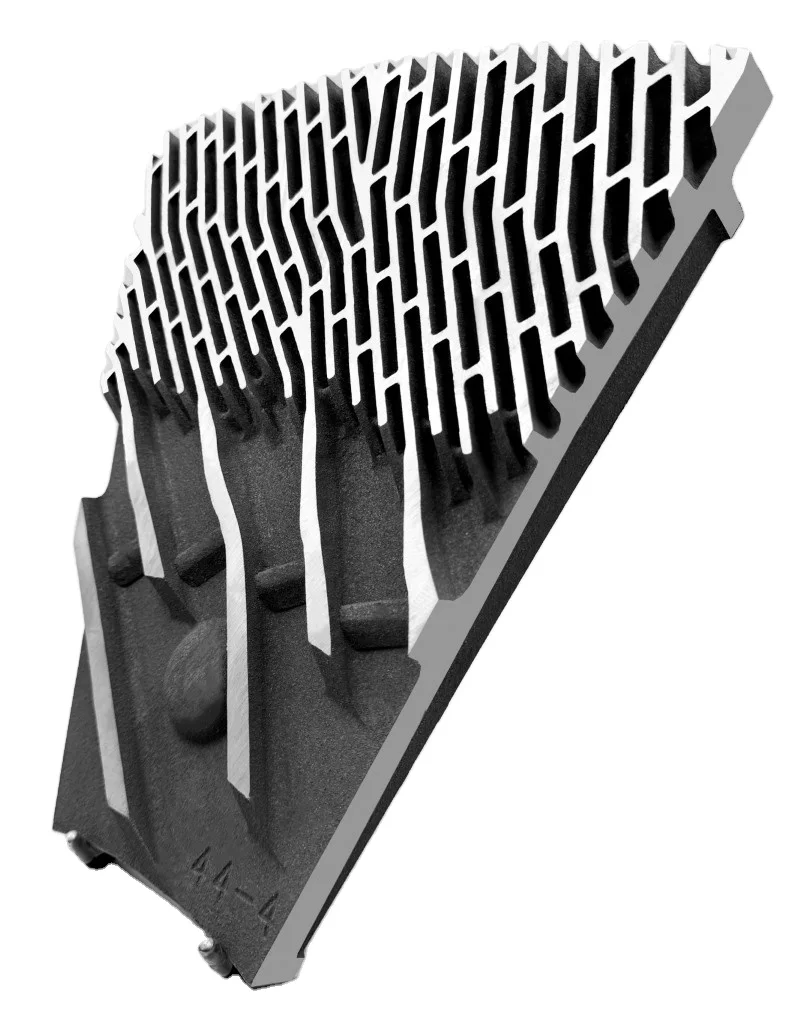

In the pulp, paper, and medium-density fiberboard (MDF) industries, disc and plate refiners are at the core of the fiber preparation process. The performance and longevity of these critical components directly impact product quality, energy consumption, and operational costs. Our specialized casting services are engineered to produce high-wear refiner plates and discs for a wide range of defibrator machines, delivering unmatched durability and precision for both paper pulping and MDF production.

Premium Materials for Extreme Abrasion and Impact

We select advanced alloys designed to withstand the specific wear mechanisms of fiber processing:

High-Chromium White Iron (HCWI): The industry benchmark for severe abrasion resistance. Our grades (e.g., ASTM A532 Class III Type A, with 25-28% Cr) offer a hardened microstructure (60-65 HRC) that resists the grinding action of wood fibers, bark, and contaminants.

Nickel-Chromium White Iron (Ni-Hard): Provides excellent as-cast hardness and a cost-effective solution for certain applications.

Tough Alloy Steels: For defibrator machines in MDF mills that encounter high-impact forces from knots or recycled material, we offer alloy steels that combine high surface hardness with a tough core to resist cracking and chipping.

Every batch is verified through spectral analysis to ensure precise chemistry, guaranteeing consistent wear performance and mechanical properties.

Precision Manufacturing and Machining Process

Our integrated manufacturing approach ensures that every disc and plate meets the exacting standards required for high-speed, balanced operation.

Advanced Molding: We utilize resin sand molding and the NOSAKA process to produce large-diameter castings with exceptional dimensional stability, precise pattern definition, and sound internal integrity.

Controlled Heat Treatment: A critical, multi-stage process of austenitizing, quenching, and tempering is applied to develop the optimal martensitic microstructure. This maximizes abrasion resistance while providing the necessary toughness to prevent catastrophic failure.

CNC Machining: Critical features—including mounting surfaces, bolt holes, and the center bore—are precision-machined on CNC equipment. This guarantees perfect fitment, alignment, and, most importantly, dynamic balance, which is vital for smooth, vibration-free operation at high rotational speeds.

Rigorous Quality Assurance: Each component undergoes dimensional inspection (using CMMs and optical scanners) and non-destructive testing (like dye penetrant) to validate surface and internal quality.

Key Performance Advantages

Maximized Wear Life: Superior materials and heat treatment significantly extend operational periods between plate changes, reducing downtime and maintenance costs.

Consistent Fiber Quality: Precisely replicated grinding patterns ensure uniform fiber fibrillation and size distribution, which is critical for the strength and quality of paper and MDF.

Energy Efficiency: Optimized plate design and smooth surfaces help reduce the specific energy required for refining.

Operational Reliability: Excellent dynamic balance protects the refiner's bearings and mechanical seals from vibration-induced damage, ensuring long-term machine health.

Applications for Major Machine Brands

Our castings serve a broad spectrum of equipment, including defibrators for MDF mills and disc refiners for paper pulping from manufacturers like Andritz, Voith, Valmet, Pallmann, and Dieffenbacher.

Ensure your refining process operates at peak efficiency and lowest cost-per-ton. Partner with us for refiner plates and discs that deliver proven performance. Contact our engineering team today to discuss your specific machine model and operational requirements.

Product name: |

Grind segment |

Specification: |

14-16",17-18",20-24",26-30",42-48",52-58",CC450 |

Material: |

Nickel hard alloy Steel |

Usage: |

Inox Stainless Steel Metal |

Color: |

Natural |

Shape: |

Customized Shape |

Feature: |

Durable |

MOQ: |

1 Piece |

Warranty |

3 years |

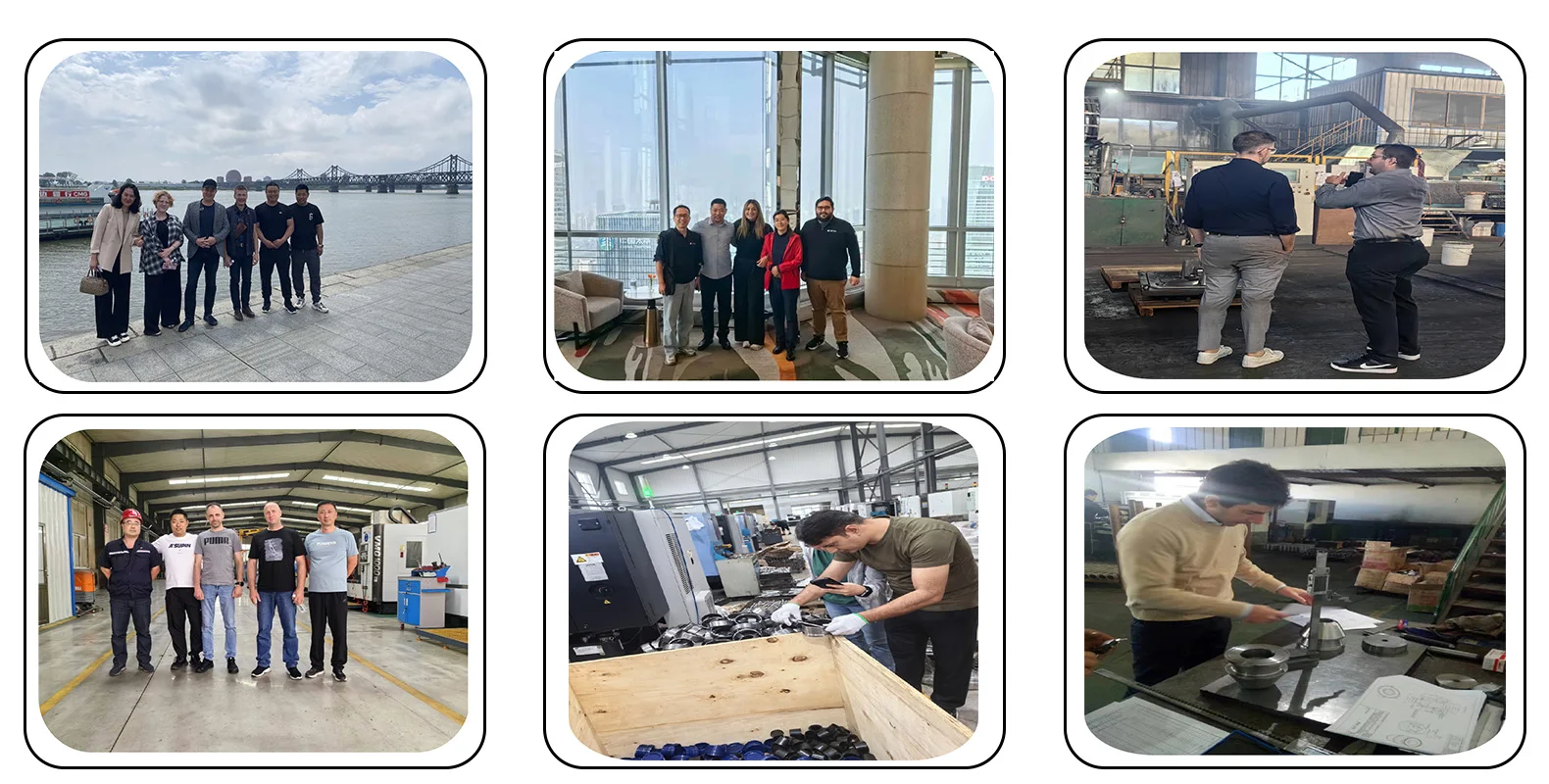

Q1. What is the advantage about your company? |

||||||||

A1. Our company has professional team and professional production line. |

||||||||

Q2. Why should I choose your products? |

||||||||

A2. Our products are high quality and low price. |

||||||||

Q3. The logo and the color can be customized? |

||||||||

A3. Yes, we welcome you to sample custom. |

||||||||

Q4. Any other good service your company can provide? |

||||||||

A4. Yes,we can provide good after-sale and fast delivery. |

||||||||