- סקירה

- מוצרים מומלצים

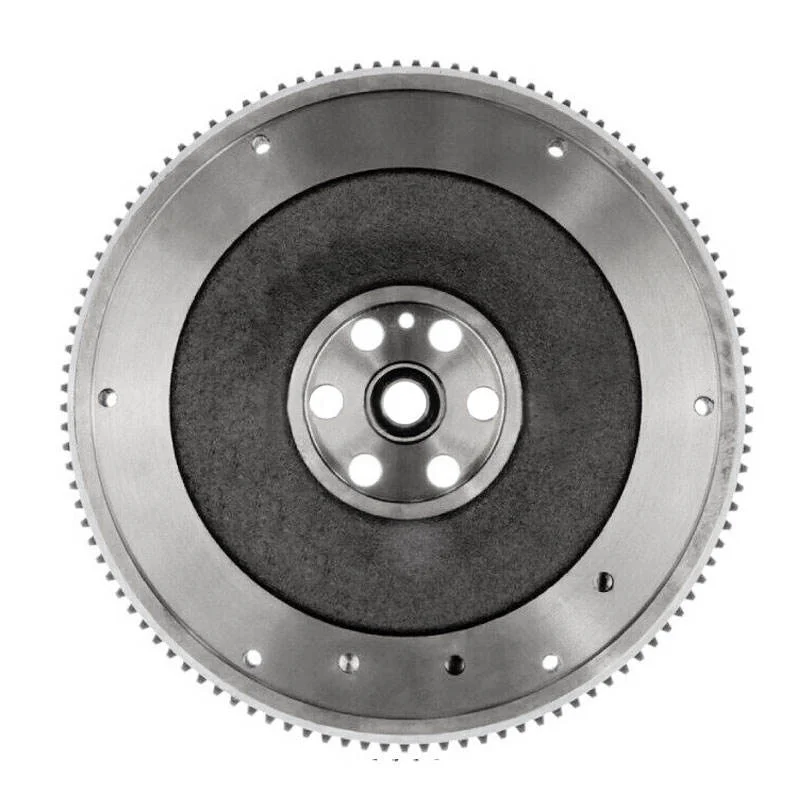

עבור חובבי רכב ובוני מקצוע העוסקים בהמרות דיסקת תנופה (FW), במיוחד ברכבים המשנים מילקוח אוטומטי למתנע ידני, דיסקת התנופה היא ממשק קריטי בין המנוע למנוף. הקטגוריה שלנו מתמחה בדיסקות תנופה לSTANDARD TRANSMISSION GEAR, שתוכננו לאספקת ביצועים מושלמים, חיבור מדויק ועמידות ערה ביישומי תיבת הילוכים עם מתח גבוה.

חומר איכותי ואמינות מת'allurgic

גלגלי התנופה שלנו יצוקים במדויק מברזל נודולרי או רקיע איכותי (למשל, GGG70). חומר זה נבחר בשל יחס חוזק-משקל מעולה, יציבות תרמית מעולה ועמידות יוצאת דופן לעייפות. בניגוד לברזל אפור סטנדרטי, ברזל נודולרי מספק קשיחות משופרת בפני פגיעות, שהיא חיונית להתמודדות עם עומסי הלם פתאומיים ומחזורי הפעלה חוזרים ונשנים של מצמד ביצועים גבוהים. עמידותו הטבועה של החומר בפני עיוות תחת חום גבוה מבטיחה מגע עקבי של המצמד ומונעת רעידות, ומספקת העברת כוח חלקה ואמינה מהמנוע לפיר הקלט של תיבת ההילוכים.

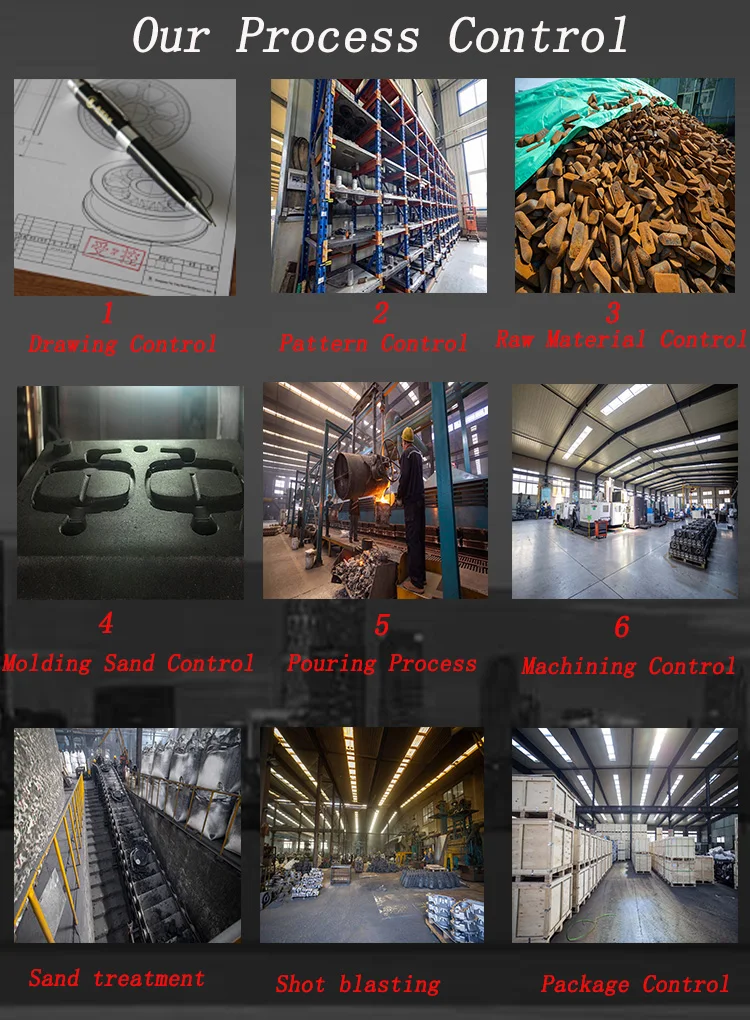

תהליך ייצור עם בקרת דיוק

ייצור מתחיל בתהליך יציקה מתקדם ליצירת ריפוד כמעט מדויק עם מבנה גרגירים צפוף ואחד. יציקה זו עברה סדרה של פעולות מכונה קריטיות על מרכזיות CNC ומכונות טorno. אנו משיגים שטח סובלנות מדויק להחלקת משטח החיכוך, קוטר חלל יתד הטייס, ומשטח ההרכבה של דף הציר האחורית. כל תנופה מאוזנת דינמית לרמה גבוהה כדי להשמיד rung שיכולים לפגוע במיסב המנוע ולגרום להרמוניה במערכת הנע, ומבטיחה תפעול חלק במהירות סל"ד גבוהה. הצעד האחרון כולל לעתים קרובות עיבוד גריסה או הקפה כדי לספק את הסיומת המשטח האופטימלית לסוג הספציפי של דסקית embrague (אורגנית, קרמית או מתכת מסילדרת).

יישום מיוחד להמרות FW

קטגוריה זו של מוצרים מיועדת במיוחד לפרויקטים של המרה. דיסקי הטייס שלנו מעוצבים כדי להתאים את דפוס הברגים של המנוע המקורי ואת גודל השעון, תוך כדי שנותנים את עובי הנכון וקוטר משטח החיכוך עבור תיבת הילוכים ידנית ממוקדת וקומפלט הצמד. זה מבטיח פעילות נכונה של הצימוד, חיבור נכון של מנוע ההפעלה, והנדסה כללית נכונה של מערכת הינע. הם מהווים בסיס להחלפה מוצלחת במגוון רחב של שימושים, החל משיקום מכוניות מוסקל קלאסיות ועד לבנייה מודרנית של ביצועים, ומציעים ביצועים חזקים ואמינות שמבוקשים על ידי מתרגמים.

בחרו בדיסקי הטייס המיוחדים שלנו לפרויקט ההמרה הבא שלכם – הפתרון המכריע לאינטגרציה של תיבת הילוכים ידנית עם עמידות מעוצבת בדיוק.

מדוע אנו מכונים מומחי OEM במניפולדים? |

אנו מפתחים מעל 100 סוגים שונים של אסימונים בכל שנה |

||||||

תהליך הייצור של דנדונג פנגשין לאסימונים |

הכנה של שרטוט: היסוד של דיוק, סריקת 3D ושרטוט: מהנדסים מקצועיים שלנו משתמשים בסורקים מתקדמים להמרת דוגמאות לשרטוטים דו-ממדיים/תלת-ממדיים (7–10 ימים). |

||||||

פיתוח תבניות ודוגמאות: שם השקעת הזמן משתלמת |

מורכבות: לעתים קרובות נדרשים למאגרי פליטה 3–5 סטים של תבניות מתכת ( לעומת סט אחד לתבניות פשוטות יותר ). זמן מוביל: 35–40 ימים לתבניות מרובות חריצים; 25–30 ימים לעיצובים פשוטים יותר. |

||||||

הזמנות ראשוניות וylie batches: הגדלה באחריות |

Allocaion מכונה: הזמנת מניפול אחד עלולה לכבס 2–3 מכונות יציקה. המתקן שלנו עם 16 מכונות מסדר את ההזמנות דחופות ועוסק בשיתוף עם יציקות שותפות לבניית ליבות עזר. |

||||||

איך משקיעים יכולים להפחית את התעכומים |

הק allocating 8–12 שבועות לפיתוח דגם/דגימה. הקפצה על תהליך זה עלולה לגרום לכשלים באיכות. האצווה הראשונה לוקחת 20–30% יותר זמן בשל סדרת עדכוני תהליך. לאחר האישור, זמני המובילות מתייצבים. |

||||||

מכירה מוקדמת

בִּמְכִירָה

לאחר מכירה

תוצאות → אנו מזמינים אתכם ליצור קשר כדי לקבל פתרון מותאם אישית.

איך הפכה פנגשין דנדונג לייצרנית מובילה של אסימבי מפלט

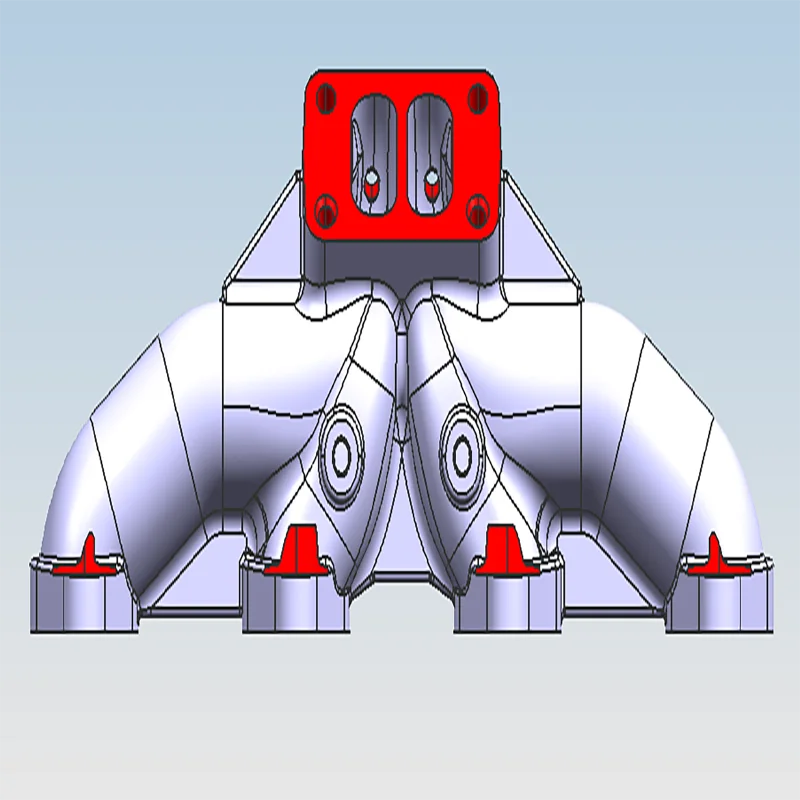

עיצובים תהלוכיים נגזרים משרטוטים הנדסיים

סקנרים תלת-ממדיים

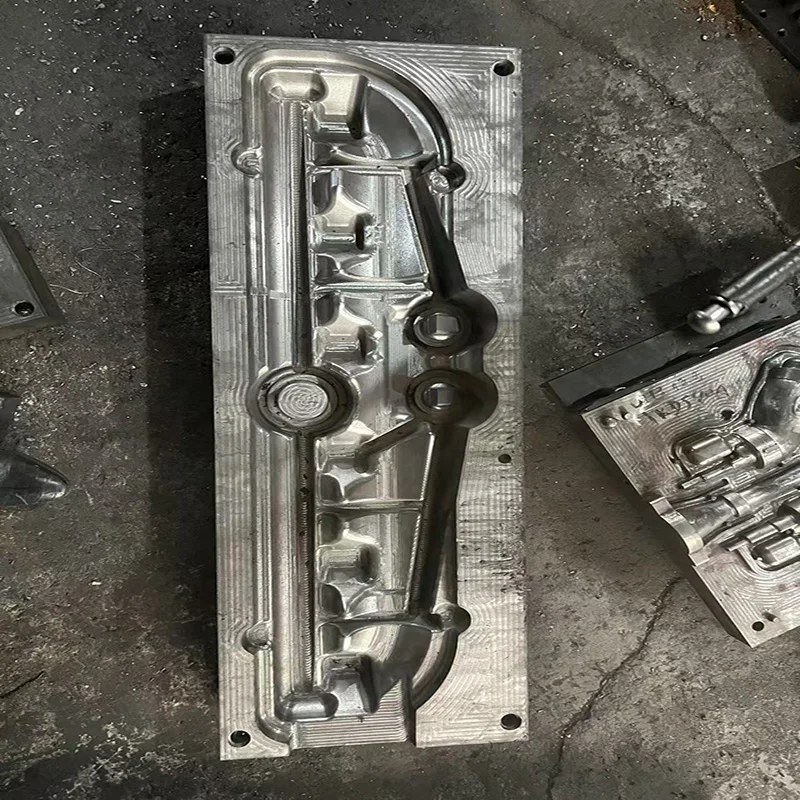

תבנית מתכת למנהרת פליטה, יציקת חול מוכתם

תבנית מתכת לאוסף עישן, יציקה בחול

תבנית פליז עירור

מכונה ליצירת מolds

יציקת חול מוכתם

מachines לציפוי

R&D

קיבולת ייצור

בקרת דפוס

abaqus, Moldflow ו-Moldex 3D, מסמלצים מערכת הזנה, מפחיתים פגמים בזריקה ומשפרים יעילות.

בקרת חומרי גלם

Machining Control