- סקירה

- מוצרים מומלצים

מציגים בפניכם את דיסקת התנופה למשאיות אמריקאית יצוקת חול של פנגשין עבור MACK 530GB3174 – הפתרון המושלם לכל צרכיכם בתחום המשאיות הכבדות.

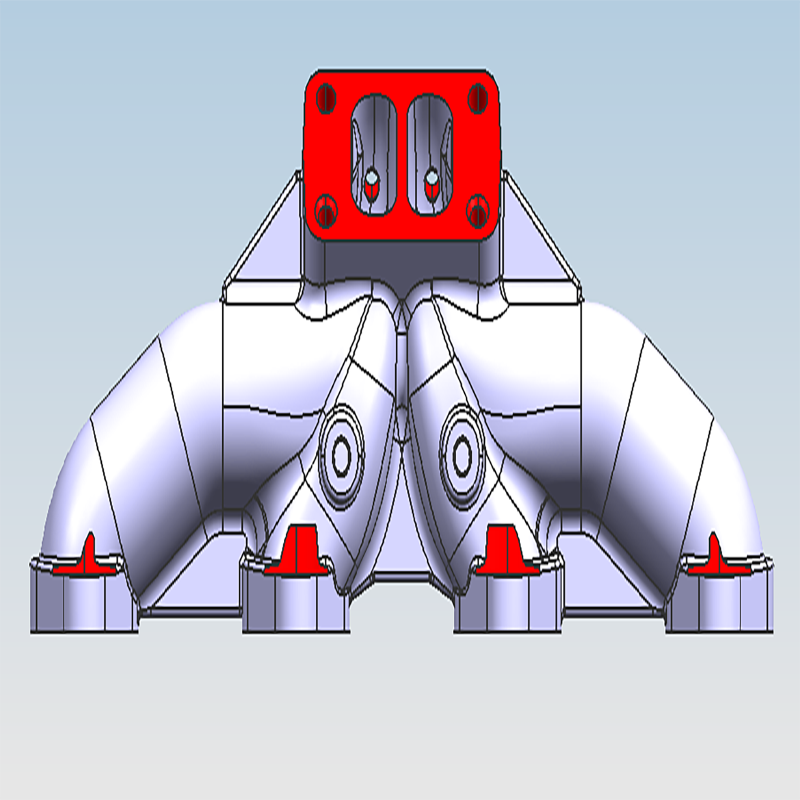

דיסקת התנופה המצוינת הזו נועדה במיוחד למודל MACK 530GB3174, ומבטיחה התאמה מדויקת ותאימות מושלמת. היא מיוצרת בדיוק רב תוך שימוש בטכניקות יציקה אמריקאיות בחול, מה שמבטיח עמידות ואמינות שאתם יכולים לסמוך עליהן.

נבנתה מחומרים מתקדמים, דיסקת התנופה של פנגשין מיוצרת כדי לעמוד בדרישות היומיומיות הקשות בתנאי משאיות קשים. העיצוב המוצק שלה מבטיח שהיא יכולה לעמוד בדרישות של המשאית MACK 530GB3174 שלכם מבלי להקריב את הביצועים.

הגלגל הנעלי של משאית הפקת החול האמריקאית Pengxin נוצר ביצועים מומחים כדי לספק תפעול חלק ויעיל, לספק את הכוח ואת עיקול המשאית שלך צריכה לבצע במיטבו. עם גלגל הנעה זה מותקן, אתה יכול להיות בטוח שהמשאית שלך תנוע בצורה חלקה ויעילה, לשמור אותך על הכביש ולעשות את העבודה.

בין אם אתם נושאים מטענים כבדים, נווטים באזורים מאתגרים, או פשוט מטיילים במורד הכביש המהיר, הגלגל הנעלי של משאית הפקת חול אמריקנית פנגקסין עבור MACK 530GB3174 עומד למשימה. בנייתה הגבוהה והביצועים האמינים שלה הופכים אותה לבחירה אידיאלית עבור בעלי משאיות הדורשים את המיטב ממכוניותיהם.

אל תסכימו לדייספלים שגרתיים שלא מצליחים לעמוד בדרישות של הקמענכם. שדרגו לדיסק טריז של פנג'ין American Sand Casting ותגלו את ההבדל ש artisanality איכותית וחומרים מתקדמים יוצרים. סמכו על פנג'ין בכל מה שקשור לחלקי הקמענכם ויהנו מהשקט הנפשי שמביא עימכם ידיעה שהקמענכם מצויד בחלקים הטובים ביותר.

השקיעו בדיסק טריז של פנג'ין American Sand Casting ל-MACK 530GB3174 ותמשכו את הביצועים של הקמענכם לרמה חדשה לגמרי. עם האיכות, קיימויות ואמינות שמעבר למה שאפשר לדמיין, דיסק הטריז הזה יutta על דעתם גם של בעלי קמענכמים ב richut קשות. שדרגו את הקמענכם היום ותגלו את ההבדל ש artisanality של פנג'ין יוצרת

| מדוע אנו מכונים מומחי OEM במניפולדים? | אנו מפתחים מעל 100 סוגים שונים של אסימונים בכל שנה |

| תהליך הייצור של דנדונג פנגשין לאסימונים | הכנת תרשימים: הבסיס לדقة, סריקת 3D ועיצוב: המהנדסים המקצועיים שלנו משתמשים בסורקים מתקדמים כדי להפוך דוגמאות לתרשימים דו-ממדיים/תלת-ממדיים - 7–10 ימים |

| פיתוח תבניות ודוגמאות: שם השקעת הזמן משתלמת | מורכבות: אסימונים לרוב דורשים 3–5 סטים של תבניות מתכת (לעומת סט אחד עבור יציקות פשוטות יותר). משך זמן: 35–40 ימים עבור תבניות רב-חדריות; 25–30 ימים בעבור עיצובים פשוטים יותר |

| הזמנות ראשוניות וylie batches: הגדלה באחריות | הקצאת מכונות: הזמנת פלנזה אחת עשויה לשלב 2–3 מכונות ייצור צורות. המתקן שלנו, הכולל 16 מכונות, ממקם הזמנות דחופות ומשתף פעולה עם מפעלים שותפים לייצור ליבות עזר |

| איך משקיעים יכולים להפחית את התעכומים | הקצו 8–12 שבועות לפיתוח תבניות/דוגמאות. הקצמצום של תהליך זה עלול לגרום לכשלים באיכות. ה партиות הראשונות נמשכות 20–30% יותר זמן עקב התאמות בתהליך. לאחר האישור, זמני ההובלה מתייצבים |

מי אנחנו

מי אנחנו Dandong Pengxin Machinery Co., Ltd., שהוקמה בשנת 1958, היא ישות עסקית פרטית המתמחה ביצ casting, עיבוד מכני ותפיסה. השטח הכולל הוא 66,000 מטר רבוע, כשמתוכם 40,000 מטר רבוע הם ה Workshops, הרכוש מגיע ל-40 מיליון דולר, ובעלת 330 עובדים, בהם 46 עובדים טכניקאים. הקיבולת השנתית מגיעה ל-100,000 טון

מצוידה בטכנולוגיות מתקדמות כמו יצ molding בלחץ גבוה וקו ייצור יפני FBO Ⅲ, מייצרת עד 30,000 טון בשנה. המתקנים כוללים תנורי קשת 12 פולס, מכונות CNC, ומרכז בקרת איכות עם מכשירי מדידה מדויקים

שירות

מכירה מוקדמת

קבלו את צרכי הקנייה שלכם → אישרו תכנית הזמנה → תנו פתרון מותאם → הציעו견תור → עשו את הדגם → מספק דגימות → ייצור המוני לאחר שדגימות אושרו בבדיקהבִּמְכִירָה

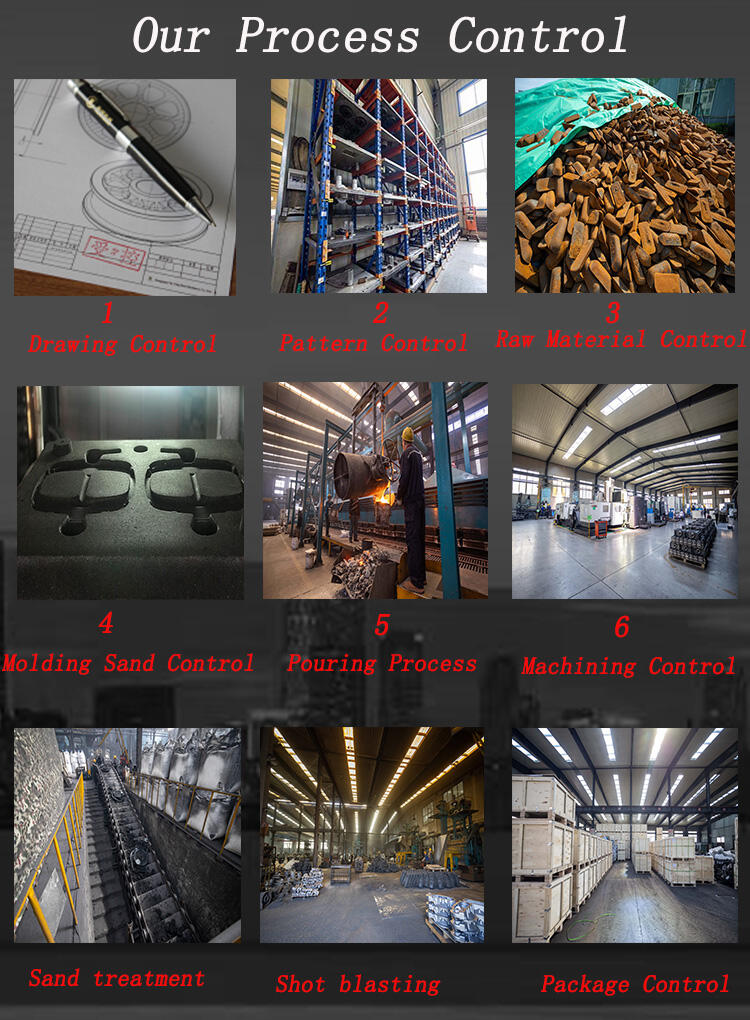

שליטה בשרטוט → שליטה בדגם → שליטה בחומר גלם → שליטה בחול היציקה → שליטה בתהליך היציקה → שליטה ביציקה גולמית ובמיכון → שליטה בדרישות אחרות → שליטה בע_PACKING_ והגשהלאחר מכירה

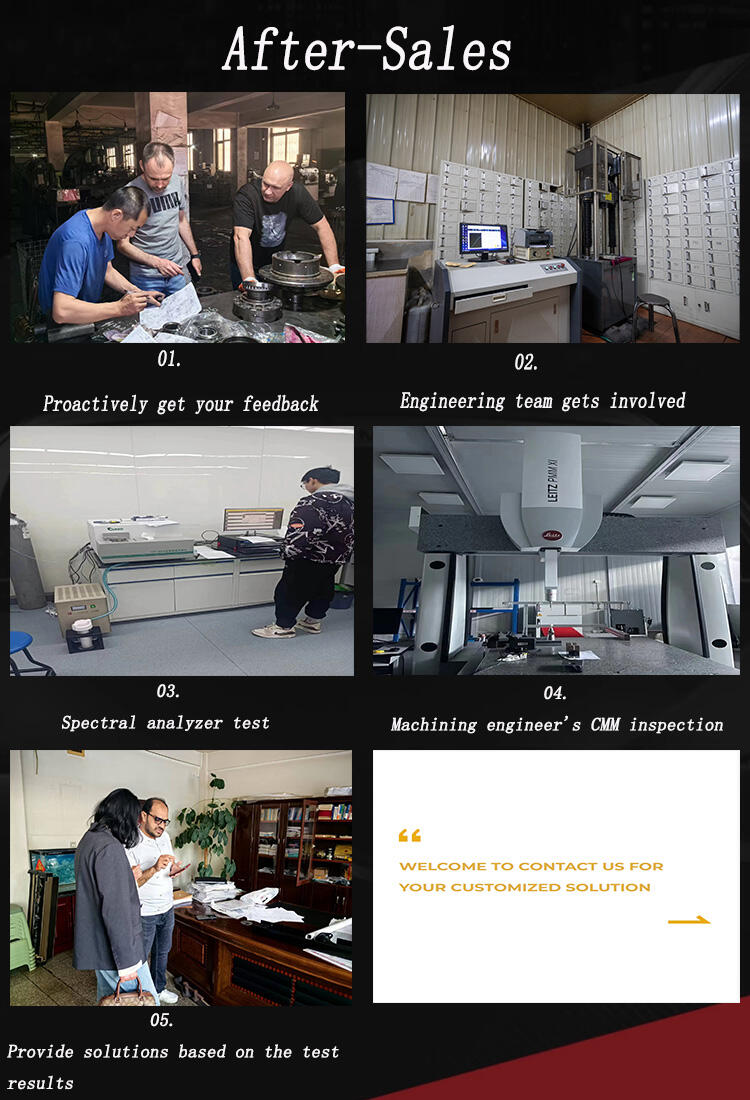

לקבלת משוב מוקדם – מעורבות של צוות ההנדסה – מהנדס יציקה בודק דגימות על פי ספקטרום הבדיקה – מהנדס עיבוד בודק באמצעות מדידה תלת ממדית על פי דגימות המלאי – מספקים פתרונות בהתבסס על תוצאות הבדיקה – בברכה פנו אלינו לפתרון המותאם אישית

איך הפכה פנגשין דנדונג לייצרנית מובילה של אסימבי מפלט

כדי להגיע לייצור מוביל עולמי של אסימבי מפלט, חברת פנגשין דנדונג הכניסה טכנולוגיות ייצור מתקדמות, חדשנות בחומרים, בקרת איכות ויעילות בשרשרת האספקה. להלן האסטרטגיות המרכזיות להשגת המטרה הזו

1. טכנולוגיות יציקה מתקדמות

(1) תהליכי יציקה ב précisión גבוהה יציקת חול ממכסה בערפיל (החומרים העיקריים לייצור הם ברזל יציקה אפור וברזל דاكتילי)

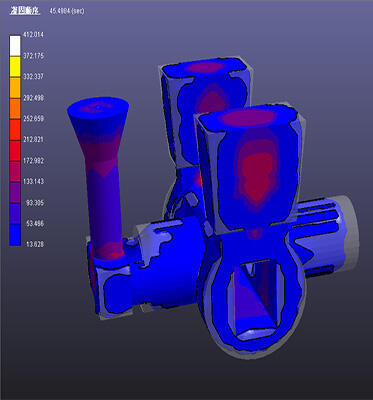

מבטיח קירות דקים, גאומטריות מורכבות עם גימור משטח ausgezeichnet (Ra 6.3–12.5 μm). אידיאלי לפליזי פלטת עם סובלנות הדוקה.(2) יציקת דגם שברirable - חומרי היצור העיקריים הם פליז אל-חלד 316 ופליז עמיד בחום משמש לדיירי טורבינה איכותיים ורכיבי פליטה לתחרות, במיוחד לאוטובוסים מסחריים מסוימים בארצות הברית

(3) ייצור בשפכה לפי סולמות אלומיניום

פתרונות קלים למערכות פליטה של רכבים היברידיים/חשמליים, יציקת כבידה היא השיטה המועדפת לייצור המוני של אסימוני פליטה, הכוללת ניסור מתכות כמו ברזל יציקה או אלומיניום והזרקת החומר המותך לתבניות פליז חמות מראש על ידי כוח הכבידה בלבד. בתהליך זה התבניות מתמלאות באופן טבעי ללא שימוש בלחץ חיצוני, אם כי בגרסאות מתקדמות יישום מינימלי של לחץ (0.2-0.5 באר) נעשה למורכבות גאומטריות. שיטה זו, שמזילה עלויות, מייצרת רכיבים בעלי עובי דופן אחיד של 3-6 מ"מ ומשטח חלק, מציעה שלמות מתלורגית טובה יותר וקצבים גבוהים יותר לייצור בהשוואה ליציקת חול, ולכן היא אידיאלית למערכות פליטה עמידות הדורשות איכות אחידה בכמויות גדולות

2. סטנדרטים לאיכות ואישור תקן תאום לתקן ISO 9001/TS 16949 (IATF 16949) → בדיקת דליפה ולחץ מבטיחה צינורות גז חסינים ב-100% בדיקות מחזור טמפרטורה → מדמה 10+ שנים של עייפות תרמית סריקת 3D ובדיקה באמצעות מדידה השוואתית (CMM) → מאשרת דיוק ממדי - ±0.1 מ"מ

עיצובים תהלוכיים נגזרים משרטוטים הנדסיים

סקנרים תלת-ממדיים

תבנית מתכת לצינור אגז, יציקת חול מומרה

תבנית מתכת לצינור אגז, יציקת חול

תבנית פליז עירור

מכונה ליצירת מolds

יציקת חול מוכתם

מachines לציפוי

R&D

קיבולת ייצור

בקרת דפוס

בקרת חומרי גלם

Machining Control