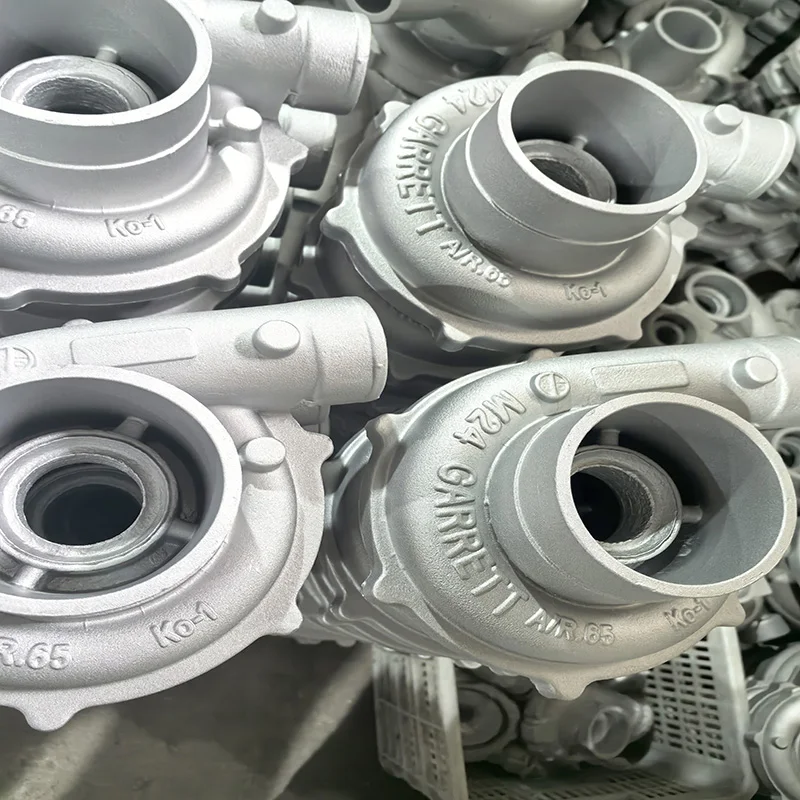

Custom Metalworking Casting Service for Brass Steel Precision Investment Casting Aluminum Die Cast Parts

- Overview

- Recommended Products

As a specialized manufacturing partner, we provide comprehensive custom metalworking solutions integrating precision investment casting for brass and steel components with advanced aluminum die casting technologies. Our integrated approach delivers superior metal parts that meet exact specifications across diverse industrial applications, combining traditional craftsmanship with modern manufacturing excellence.

Material Expertise and Performance Characteristics

Our services encompass three primary material groups, each selected for specific performance advantages:

Brass Investment Casting

We utilize high-quality brass alloys (C85700, C87500) known for their excellent corrosion resistance, superior machinability, and natural antimicrobial properties. These alloys demonstrate good tensile strength (275-550 MPa) and outstanding thermal/electrical conductivity, making them ideal for plumbing, marine, and electrical applications.

Steel Investment Casting

Our steel casting capabilities include carbon steels (1020, 1045) and stainless steels (304, 316, 17-4PH), offering exceptional strength-to-weight ratios and durability. These materials provide tensile strength ranging from 485-1310 MPa, excellent impact resistance, and reliable performance in high-stress environments.

Aluminum Die Casting

We specialize in premium aluminum alloys (A380, ADC12) valued for their lightweight characteristics and excellent mechanical properties. These materials offer good corrosion resistance, high strength-to-weight ratios, and superior thermal conductivity, with tensile strength reaching 324 MPa.

Advanced Manufacturing Processes

Our production methodology leverages two complementary casting technologies:

Precision Investment Casting

The lost-wax process enables production of complex, near-net-shape components with exceptional dimensional accuracy and surface finish. Our investment casting capabilities feature:

Ceramic shell molding technology for intricate geometries

Tight tolerance maintenance (±0.125 mm per 25 mm)

Superior surface finishes (Ra 3.2 μm or better)

Minimal machining requirements and material waste

High-Pressure Die Casting

Our aluminum die casting operations utilize advanced cold-chamber technology with:

Computer-controlled injection parameters

Precision temperature management systems

Rapid production cycles for high-volume requirements

Consistent dimensional repeatability across production runs

Integrated Secondary Operations

Our comprehensive metalworking services include complete secondary processing:

CNC machining of critical features and mounting surfaces

Precision drilling, tapping, and milling operations

Deburring and surface preparation

Heat treatment for enhanced mechanical properties

Quality verification and dimensional inspection

Quality Assurance Protocol

We maintain rigorous quality control throughout our manufacturing process:

Material certification and traceability documentation

First article inspection and production part approval

Coordinate measuring machine (CMM) validation

Non-destructive testing including X-ray and liquid penetrant

Mechanical property testing and verification

Statistical process control implementation

Industrial Applications and Solutions

Our casting services support diverse industry requirements:

Automotive Components: Engine parts, transmission elements, and structural brackets

Aerospace Applications: Turbine components, structural elements, and instrumentation parts

Marine Hardware: Corrosion-resistant fittings, valve components, and underwater connectors

Industrial Equipment: Pump housings, valve bodies, and machinery components

Electrical Systems: Connector components, housing elements, and thermal management parts

By combining precision investment casting with advanced die casting technologies, we deliver comprehensive metalworking solutions that optimize performance, reduce production costs, and ensure reliable component performance. Our engineering team collaborates closely with clients to select the most appropriate manufacturing method based on application requirements, material properties, and production volume considerations, ensuring optimal solutions for each unique project requirement.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |