- Overview

- Recommended Products

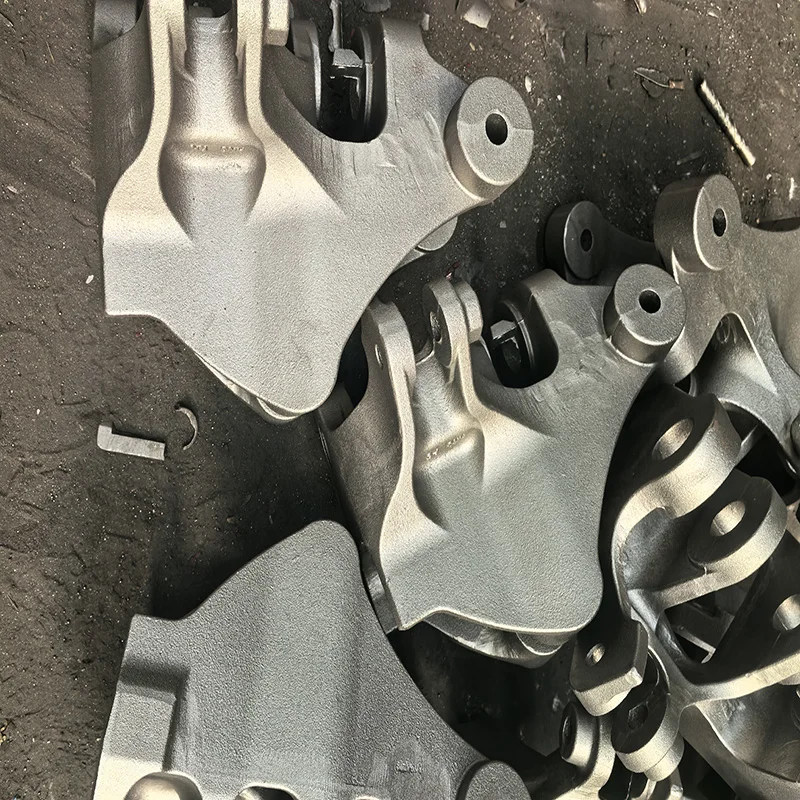

In the pursuit of manufacturing excellence for large, complex, and high-tolerance components, the synergy of advanced molding and precision machining is paramount. Our specialized service combines shell molding technology for producing high-integrity iron parts with final CNC machining to meet exact specifications. This integrated approach is particularly effective for manufacturing large components, such as those requiring resin epoxy coatings for extreme protection, delivering unmatched dimensional accuracy and durability for demanding industrial applications.

Superior Process: Shell Molding for Iron Parts

Shell molding, also known as Croning process, is a sophisticated casting technique that uses a resin-coated sand to form a thin, rigid mold. This method offers significant advantages over traditional sand casting, especially for medium to high-volume production:

Excellent Dimensional Accuracy and Surface Finish: Produces castings with smoother surfaces and tighter tolerances, significantly reducing the amount of stock required for subsequent machining.

High Production Rate: The process is highly repeatable and efficient for producing consistent, high-quality castings.

Minimal Casting Defects: The rigid mold provides excellent resistance to veining and swelling, resulting in a denser and more reliable casting with a fine-grained microstructure.

Material and Performance: The Strength of Cast Iron

We utilize gray iron for its superior damping capacity and compressive strength, and ductile iron for applications requiring high tensile strength, toughness, and impact resistance. The shell molding process enhances these inherent properties by producing a sound, homogeneous casting with excellent mechanical characteristics, ready for precision machining.

Precision Finishing with CNC Machining

The shell molding process creates a superior near-net-shape part, but critical functional surfaces require ultimate precision. This is where CNC machining is indispensable. Our advanced CNC milling and turning centers perform critical operations:

Machining precise mounting faces and flanges.

Boring accurate diameters for bearings or seals.

Drilling and tapping bolt holes to exact locations.

Creating complex geometries that are impossible to cast.

This ensures the final part integrates perfectly into your assembly, guaranteeing performance, interchangeability, and leak-free operation.

Application for Large Parts with Resin Epoxy

This combined process is ideal for producing large components like valve bodies, pump housings, and machinery bases. For parts exposed to highly corrosive environments, we can apply a protective resin epoxy lining or coating after machining. This thick, chemically resistant barrier provides an extra layer of defense, making the component suitable for use in chemical processing, marine, and wastewater treatment applications.

Contact us today to leverage our expertise in shell molding and CNC machining for your large, high-precision iron parts. We deliver integrated solutions that meet your most challenging requirements.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |