- Overview

- Recommended Products

Ensure optimal performance and reliability for your Toyota 4Runner, T100, or Tacoma (1995-2004 models) with our new LFW200 flywheel, specifically engineered for the 2.7L 3RZ-FE engine. This precision-crafted replacement component restores factory performance, providing smooth engagement, durable operation, and perfect compatibility for your vehicle's clutch system. Manufactured to meet or exceed OEM specifications, it delivers the quality and reliability you expect for your Toyota truck or SUV.

Premium Material and Advanced Engineering

Constructed from high-grade cast iron, this flywheel is engineered for optimal performance and longevity. The material is carefully selected to provide:

Excellent Heat Dissipation: Effectively manages and disperses the intense thermal energy generated during clutch engagement, preventing heat spots and warping that can lead to chatter and premature wear.

Superior Strength and Durability: The robust cast iron construction withstands the high torque and rotational forces of the 2.7L 3RZ engine, ensuring reliable performance under demanding driving conditions.

Precision-Balanced Design: Each flywheel is dynamically balanced to minimize vibration, contributing to smoother engine operation, reduced wear on crankshaft bearings, and enhanced driving comfort.

Precision Manufacturing Process

This LFW200 flywheel is produced using advanced manufacturing techniques to guarantee quality and fit:

High-Quality Casting: The foundation is a precision sand-cast component, ensuring a dense, consistent microstructure free from flaws that could compromise integrity.

CNC Machining: Critical surfaces, including the friction face and clutch mounting surface, are finished on CNC machines. This guarantees exact flatness, runout tolerances, and the correct step height, which are crucial for proper clutch engagement and release.

Surface Finishing: The friction surface is precisely machined and finished to provide the ideal texture for the clutch disc to grip, ensuring smooth engagement and long-lasting performance.

Direct Fit and Easy Installation

Engineered as a direct OEM replacement, this flywheel features:

Perfect Compatibility: Designed to seamlessly fit 1995-2004 Toyota 4Runner, T100, and Tacoma models equipped with the 2.7L 3RZ-FE engine.

Precise Bolt Pattern and Ring Gear: Manufactured to exact specifications for a perfect fit on the engine's crankshaft flange and correct engagement with the starter motor.

Restore Performance and Reliability

Ideal for clutch replacement jobs, this new flywheel eliminates the issues associated with resurfacing worn OEM units. It provides a fresh, flat surface for the new clutch disc, ensuring maximum contact and power transfer. By choosing this LFW200 flywheel, you are investing in a component that restores factory-like shifting smoothness and dependable performance for your Toyota.

Why are we called OEM experts in Exhaust Manifolds |

We develop over 100 different types of exhaust manifolds every year |

||||||

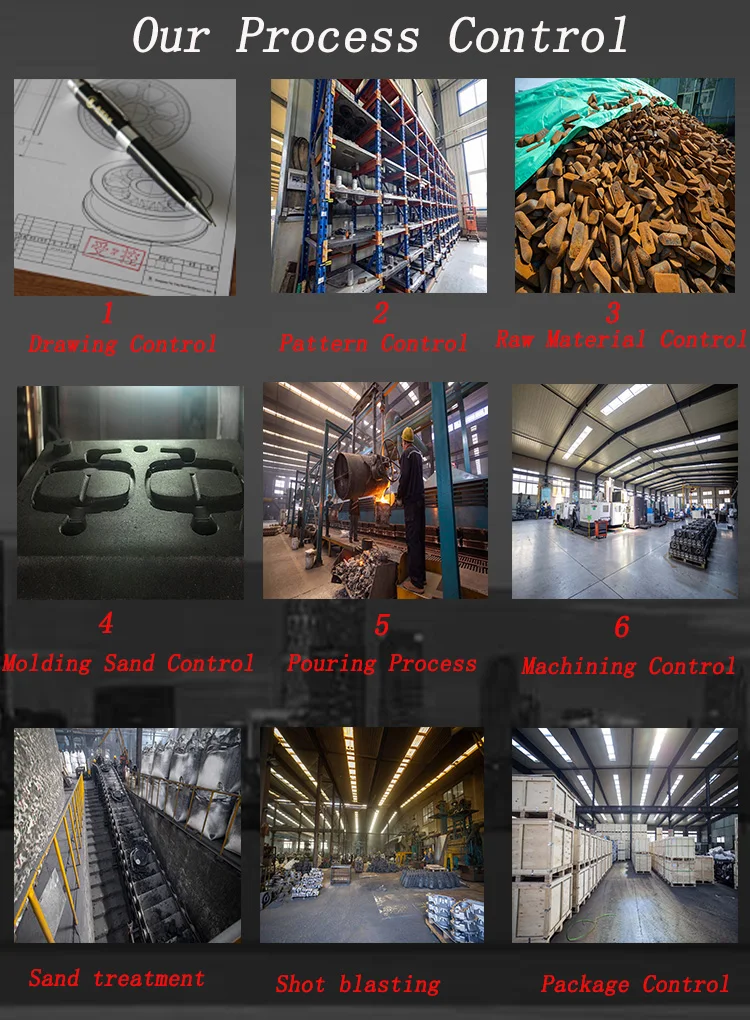

Dandong Pengxin Production Process for Exhaust Manifold |

Drawing Preparation: The Foundation of Precision,3D Scanning & Drafting: Our professional engineers use advanced scanners to convert samples into 2D/3D drawings (7–10 days). |

||||||

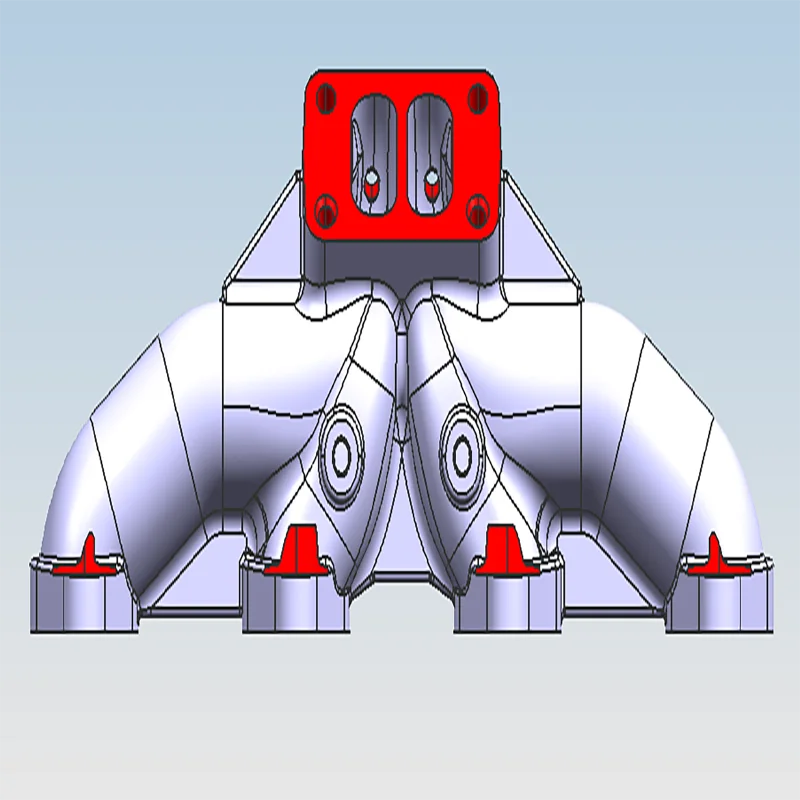

Pattern & Sample Development: Where Time Invested Pays Off |

Complexity: Exhaust manifolds often require 3–5 sets of metal patterns (vs. 1 set for simpler castings).Lead Time: 35–40 days for multi-cavity patterns; 25–30 days for simpler designs. |

||||||

Initial Orders & Batch Production: Scaling Responsibly |

Machine Allocation: One manifold order may occupy 2–3 molding machines. Our 16-machine facility prioritizes urgent orders and collaborates with partner foundries for auxiliary cores. |

||||||

How Investors Can Mitigate Delays |

Allocate 8–12 weeks for pattern/sample development. Compressing this risks quality failures. First batches take 20–30% longer due to process fine-tuning. Post-approval, lead times stabilize. |

||||||

Pre-sales

On Sale

After-Sales

results→Welcome to contact us for your customized solution.

How did Dandong Pengxin Become a Top Manufacturer of Exhaust Manifold

Process designs derive from engineering drawings

3D scanners

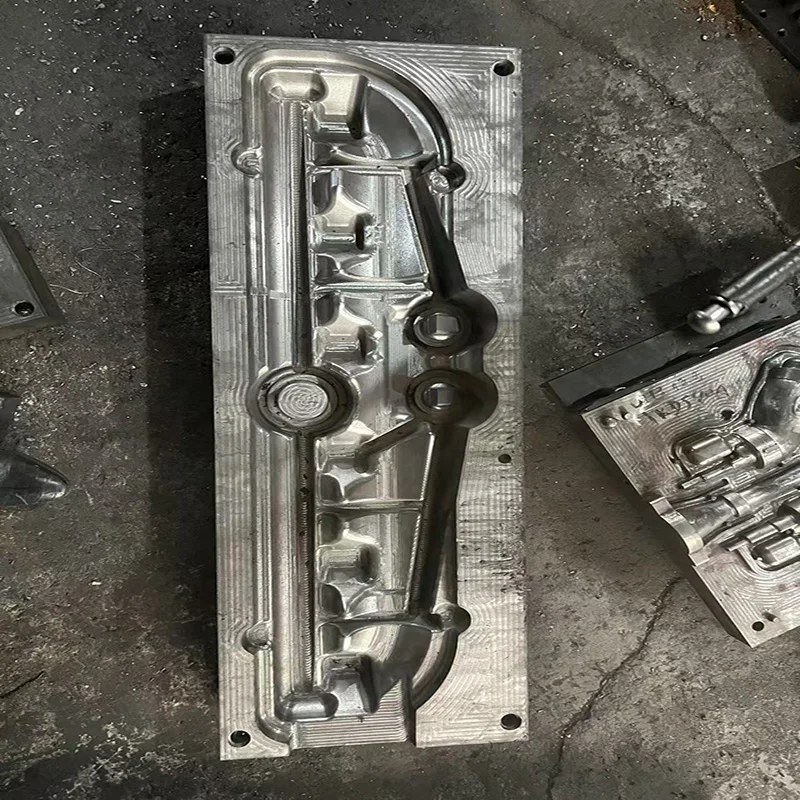

Metal Mold for Exhuast Manifold,Coated sand casting

Metal Mold for Exhaust Manifold,Sand Casting

Exhaust Manifold Core Box

Shell Molding Machine

Coated sand casting

Molding Machines

R&D

Production Capacity

Pattern Control

Abaqus,Moldflow and Moldex 3D, simulate feeding system, reduce casting defects and improve efficiency.

Raw Material Control

Machining Control