Customized Automatic Tapping Machine Aluminum Gravity Casting in Machine Parts Customized Casting Services

- Overview

- Recommended Products

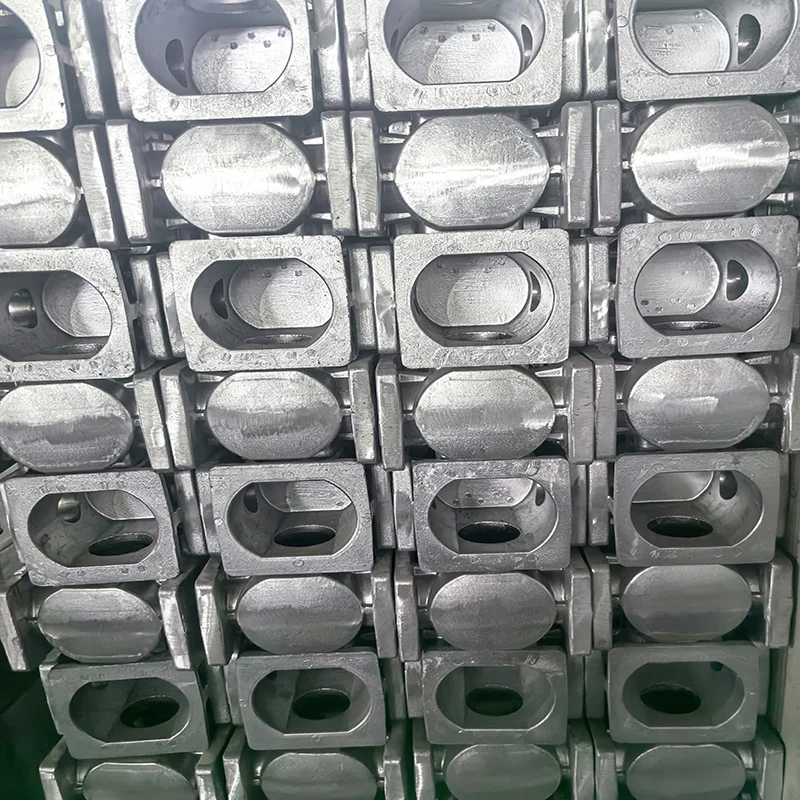

As a specialized manufacturer in industrial machinery components, we provide customized aluminum gravity casting services specifically engineered for automatic tapping machine parts. Our manufacturing expertise combines advanced gravity casting technology with precision engineering to deliver components that ensure exceptional durability, dimensional stability, and reliable performance in high-precision tapping and threading operations.

Material Excellence and Performance Characteristics

We utilize premium A356-T6 aluminum alloy and ZL104 aluminum alloy specifically formulated for automatic tapping machine applications. The A356-T6 alloy offers exceptional mechanical properties with tensile strength of 234 MPa and yield strength of 193 MPa after heat treatment, providing optimal strength for vibration resistance during tapping operations. ZL104 aluminum alloy demonstrates excellent casting fluidity with tensile strength of 240 MPa, ensuring precise reproduction of complex geometries while maintaining good pressure tightness. These materials feature:

Superior vibration damping capacity for smooth operation

Excellent wear resistance against continuous mechanical stress

Outstanding thermal stability maintaining dimensional accuracy

Good machinability for precision post-casting operations

Corrosion resistance for various industrial environments

Advanced Gravity Casting Manufacturing Process

Our production methodology employs sophisticated gravity casting techniques:

Permanent Mold Technology

We utilize precision-engineered steel molds with advanced thermal management systems that ensure:

Controlled solidification for superior metallurgical properties

Consistent dimensional accuracy across production runs

Reduced porosity and improved mechanical strength

Enhanced surface finish quality (Ra 3.2-6.3 μm)

Process Optimization

Our gravity casting process incorporates:

Computer-controlled pouring temperature management

Automated mold coating application systems

Real-time process monitoring and data acquisition

Strategic cooling channel design for optimal solidification

Quality Assurance and Performance Validation

Each tapping machine component undergoes rigorous quality control:

X-ray inspection for internal defect detection

Coordinate measuring machine dimensional verification

Mechanical property testing confirming specifications

Surface quality assessment for optimal performance

Dynamic balancing testing for rotating components

Industrial Applications and Custom Solutions

Our customized casting services support critical tapping machine components:

Machine Housings: Main body castings and structural frames

Spindle Assemblies: Precision spindle housings and bearing supports

Feed Mechanisms: Slide units and feed screw housings

Base Components: Machine beds and mounting platforms

Accessory Parts: Tool holders and fixture components

By combining advanced gravity casting technology with automatic tapping machine expertise, we deliver components that provide reliable performance, extended service life, and optimal precision in industrial threading applications. Our engineering team works closely with machinery manufacturers to develop customized solutions that meet specific application requirements, ensuring perfect fitment, superior durability, and enhanced operational efficiency for automatic tapping systems.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |