- Overview

- Recommended Products

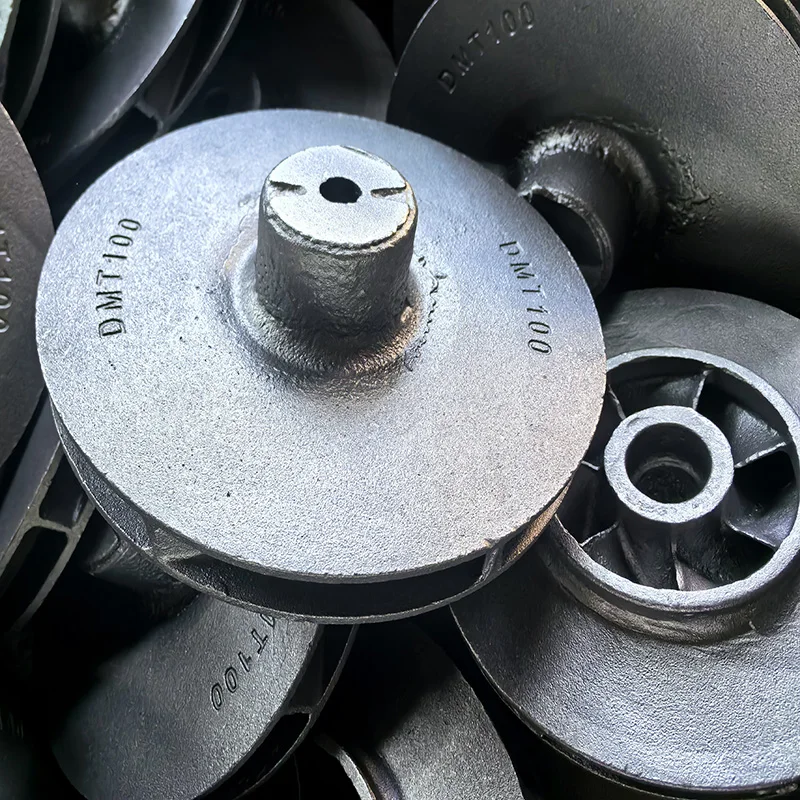

In precision mechanical systems where reliability and corrosion resistance are paramount, the Right Crank component manufactured through Stainless Steel Lost Wax Casting represents the pinnacle of manufacturing excellence. This sophisticated casting method, also known as investment casting, delivers complex geometries with exceptional dimensional accuracy and superior surface finish. Our specialized process produces right crank components that meet rigorous performance standards for aerospace, automotive, and high-end industrial applications.

Premium Stainless Steel Materials

We utilize high-performance stainless steel alloys specifically engineered for critical components:

304/304L Stainless Steel: Optimal for general corrosion resistance with excellent formability

316/316L Stainless Steel: Enhanced corrosion resistance ideal for harsh environments

17-4PH Stainless Steel: Precipitation-hardening grade offering exceptional strength-to-weight ratio

Custom Alloy Development: Tailored material compositions for specific application requirements

Advanced Lost Wax Casting Process

Our manufacturing methodology ensures uncompromising quality:

Precision Pattern Development: CAD-designed wax patterns created through injection molding

Ceramic Shell Building: Multi-layer ceramic mold formation using advanced bonding technology

Controlled Melting and Pouring: Vacuum-assisted pouring under protective atmosphere

Precision Finishing: CNC machining of critical surfaces and interfaces

Technical Specifications and Performance Characteristics

Dimensional Accuracy: Maintains tolerances within ±0.005 inches per inch

Surface Quality: Achieves 125-250 microinch Ra finish in as-cast condition

Mechanical Properties: Tensile strength up to 1100 MPa depending on alloy selection

Weight Optimization: Complex internal structures reducing component mass

Corrosion Resistance: Excellent performance in various corrosive media

Quality Assurance and Testing Protocols

Non-Destructive Examination: 100% radiographic and penetrant testing

Metallurgical Analysis: Microstructure evaluation and grain size assessment

Dimensional Verification: CMM inspection with 3D scanning capability

Mechanical Testing: Comprehensive tensile, impact, and fatigue testing

Material Certification: Full traceability from raw material to finished product

Application-Specific Engineering

Our right crank components are engineered for:

Aerospace Actuation Systems: Precision control mechanisms and linkage assemblies

Automotive Throttle Systems: Reliable performance under cyclic loading conditions

Industrial Robotics: Accurate motion transfer in automated systems

Medical Equipment: Corrosion-resistant components for hygienic environments

Marine Applications: Saltwater-resistant cranks for marine propulsion systems

Design and Manufacturing Advantages

Complex Geometry Capability: Intricate shapes impossible with other manufacturing methods

Reduced Machining Requirements: Near-net shape casting minimizes secondary operations

Material Integrity: Homogeneous microstructure with controlled grain formation

Cost Efficiency: Reduced material waste and lower total manufacturing costs

Rapid Prototyping: Quick transition from design to functional prototypes

Partner with our investment casting expertise for right crank components that deliver uncompromising performance. Our stainless steel lost wax casting process ensures superior mechanical properties, exceptional corrosion resistance, and reliable operation in your most demanding applications.

Our Services |

CNC Precision Milling Machining,CNC Precision Turning Machining, Rapid Prototyping Plastic Injection Mould Metal Stamping, Die Casting, Silicone And Rubber Mould, Aluminum Extrusion, Mould Fabrication,etc |

Material |

Aluminum Alloy:5052/6061/6063/7075 etc Brass Alloy: 3602/2604/h59/h62/etc Stainless Steel Alloy: 303/304/316/412/etc Steel Alloy: Carbon/Die Steel/etc Other Special Materials: Lucite/Nylon/Bakelite/etc Plastic, Wood, Silicone, Rubber,Or as per the customers’ requirements |

Surface Treatment |

Anodizing, Sandblasting, Painting, Powder coating, Electroplating, Silk Printing, Brushing, Polishing, Laser Engraving... |

Drawing Format |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl,etc |

Service Project |

To provide project design, production and technical service, mould development and fabrication, etc |

Testing Machine |

Digital Height Gauge, caliper, Three Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

Quality Assurance |

ISO9001:2015 Certified TUV |

Packing |

Foam, Carton, Wooden boxes, or as per the customer’s requirements |

Deliver |

DHL, FEDEX, UPS, TNT, EMS, SF Or according to customers′ requirement |