In the original equipment manufacturing sector, component reliability and precise specification compliance are fundamental requirements. Our OEM Products Grey Iron and Ductile Iron Part Sand Casting Services deliver precision-engineered solutions that meet stringent automotive, industrial, and machinery manufacturer standards. We provide comprehensive casting services that combine material expertise with advanced sand casting technology to produce components with exceptional dimensional accuracy and mechanical performance.

Premium Material Selection

Our foundry utilizes both grey iron (GG15/GG20/GG25) and ductile iron (GGG40/GGG50/GGG60) to meet diverse OEM requirements:

Grey Iron Grades: Deliver excellent compression strength (600-850 MPa) and superior vibration damping characteristics

Ductile Iron Grades: Provide tensile strength of 400-600 MPa with elongation ranging from 18% to 3%

Specialized Alloys: Feature chromium, nickel, and molybdenum additions for enhanced wear and corrosion resistance

All materials undergo rigorous quality verification including spectrochemical analysis, microstructure examination, and mechanical testing to ensure compliance with ISO 185, ISO 1083, and customer-specific standards.

Advanced Sand Casting Technology

Our manufacturing employs sophisticated resin sand casting systems:

Mold Preparation

Automated molding lines with flask sizes up to 1500×1500×500 mm

3D printed sand molds for complex core geometries

Cold box and shell molding processes for superior surface finish

Real-time mold hardness and density monitoring

Casting Operations

Computer-controlled pouring systems maintaining temperatures of 1380-1450°C

In-mold inoculation ensuring consistent graphite formation

Optimized gating and feeding systems for sound castings

Controlled cooling cycles preventing internal stresses

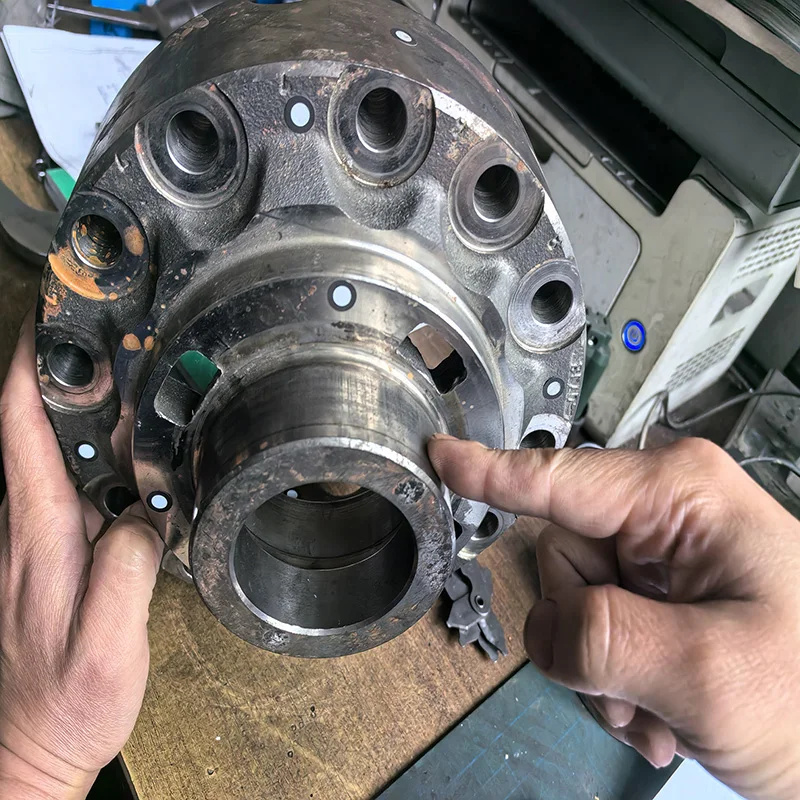

Precision Machining Integration

Our comprehensive machining capabilities include:

CNC turning and milling centers with 4/5-axis capability

Precision boring operations maintaining tolerances within ±0.02 mm

Surface grinding achieving Ra 1.6-3.2 μm finishes

Coordinate measuring machine verification

Automated deburring and cleaning processes

Performance Characteristics

Our iron castings deliver:

Dimensional accuracy within CT6-9 grade per ISO 8062

Pressure tightness tested to 3-15 bar depending on application

Surface hardness of 170-250 HB

Excellent machinability and wear resistance

Thermal stability from -40°C to 400°C

Quality Assurance System

Each component undergoes comprehensive validation:

Ultrasonic testing for internal integrity

Magnetic particle inspection for surface defects

Dimensional verification using laser scanning

Material certification with full traceability

Performance testing under simulated conditions

Technical Applications

Our OEM services cater to multiple industries:

Automotive: brake components, engine brackets, transmission parts

Hydraulic equipment: valve bodies, pump housings, cylinder blocks

Machinery: gearboxes, bearing caps, machine tool components

Agricultural: transmission cases, implement parts, structural components

Our engineering team provides complete technical support from design optimization through production, ensuring each component meets exact OEM specifications for performance, reliability, and cost-effectiveness. By combining advanced sand casting technology with precision machining capabilities, we deliver iron castings that ensure optimal performance and extended service life across diverse industrial applications.