- Overview

- Recommended Products

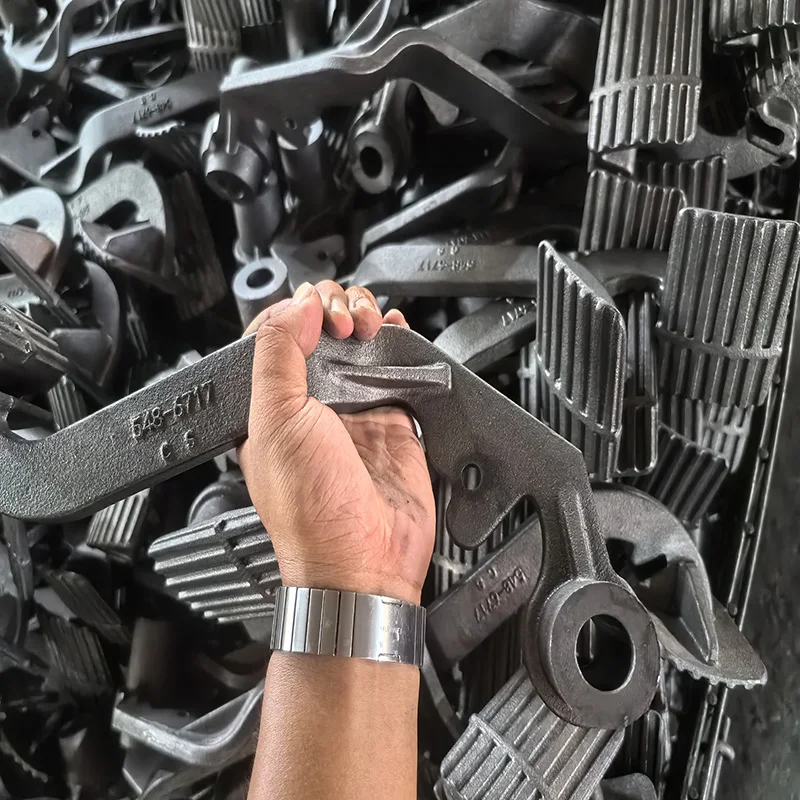

As a specialized OEM manufacturer, we provide precision CNC turning services specifically engineered for carrier roller applications, combined with comprehensive custom casting solutions. Our integrated manufacturing approach delivers carrier rollers that ensure optimal performance, extended service life, and reliable operation in demanding industrial environments, particularly for construction, mining, and heavy equipment applications.

Material Excellence and Performance Characteristics

We utilize high-grade materials specifically selected for carrier roller applications, including 4140 alloy steel and 1045 carbon steel for superior wear resistance and durability. Our ductile iron grades (65-45-12, 80-55-06) offer excellent impact strength with tensile strength ranging from 448-552 MPa, while maintaining good machinability. For applications requiring enhanced corrosion resistance, we provide stainless steel variants (304, 316) that maintain structural integrity in harsh environments. These materials demonstrate:

Superior hardness (28-32 HRC for alloy steels)

Excellent wear resistance against track chain abrasion

High impact strength for shock load conditions

Good corrosion resistance in various operating environments

Consistent performance across temperature extremes

Advanced Manufacturing Process

Our production methodology integrates precision casting with advanced CNC turning technology:

Custom Casting Services

We employ sophisticated casting techniques including:

Shell molding for superior dimensional accuracy

Resin sand casting for complex geometries

Investment casting for critical wear surfaces

Controlled melting and pouring processes

Strategic gating and risering design

Precision CNC Turning Technology

Our CNC turning capabilities feature:

Multi-axis turning centers with live tooling

Precision boring of roller internal diameters

Automated threading and grooving operations

Real-time diameter monitoring systems

Integrated measuring and compensation

Quality Assurance and Performance Validation

Each carrier roller undergoes rigorous quality control:

Ultrasonic testing for internal defect detection

Hardness verification across critical surfaces

Dimensional validation using CMM technology

Surface finish analysis for optimal sealing

Material certification to international standards

Load testing under simulated operating conditions

Industrial Applications and Solutions

Our carrier rollers serve demanding applications in:

Tracked Equipment: Excavators, bulldozers, and crawler cranes

Mining Machinery: Underground mining equipment and surface miners

Agricultural Equipment: Tracked tractors and harvesting machinery

Construction Vehicles: Compact track loaders and skid steers

Industrial Machinery: Material handling and conveyor systems

By combining advanced casting technology with precision CNC turning capabilities, we deliver carrier rollers that provide reliable performance, reduced maintenance costs, and extended service intervals. Our engineering team works closely with equipment manufacturers to develop customized solutions that meet specific application requirements, ensuring optimal dimensional accuracy, superior wear resistance, and cost-effective manufacturing for both replacement and OEM applications.

Our Services |

CNC Precision Milling Machining,CNC Precision Turning Machining, Rapid Prototyping Plastic Injection Mould Metal Stamping, Die Casting, Silicone And Rubber Mould, Aluminum Extrusion, Mould Fabrication,etc |

Material |

Aluminum Alloy:5052/6061/6063/7075 etc Brass Alloy: 3602/2604/h59/h62/etc Stainless Steel Alloy: 303/304/316/412/etc Steel Alloy: Carbon/Die Steel/etc Other Special Materials: Lucite/Nylon/Bakelite/etc Plastic, Wood, Silicone, Rubber,Or as per the customers’ requirements |

Surface Treatment |

Anodizing, Sandblasting, Painting, Powder coating, Electroplating, Silk Printing, Brushing, Polishing, Laser Engraving... |

Drawing Format |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl,etc |

Service Project |

To provide project design, production and technical service, mould development and fabrication, etc |

Testing Machine |

Digital Height Gauge, caliper, Three Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

Quality Assurance |

ISO9001:2015 Certified TUV |

Packing |

Foam, Carton, Wooden boxes, or as per the customer’s requirements |

Deliver |

DHL, FEDEX, UPS, TNT, EMS, SF Or according to customers′ requirement |