- Oorsig

- Aanbevole Produkte

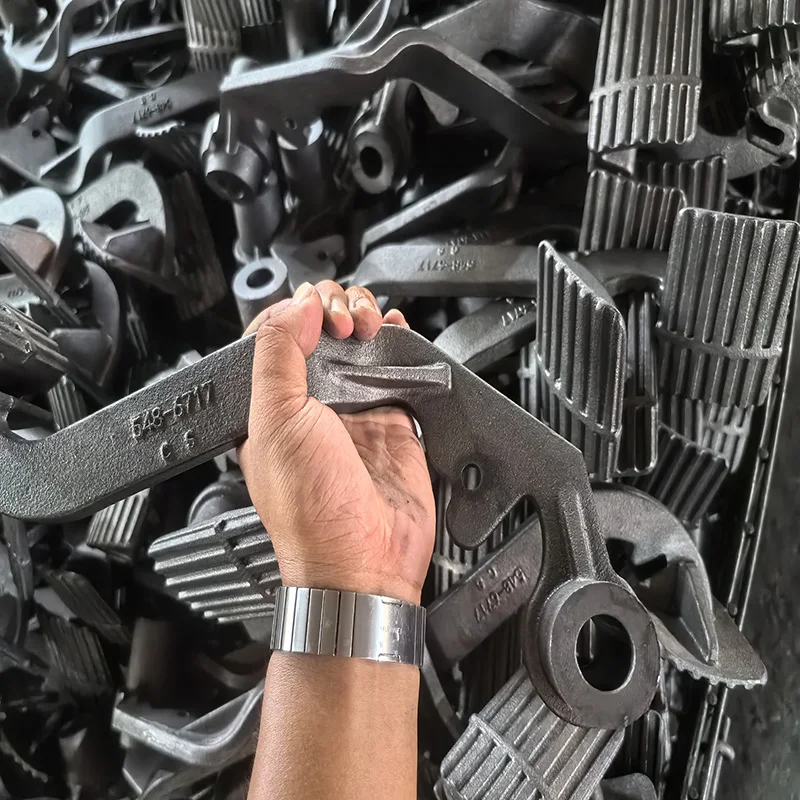

As 'n gespesialiseerde OEM-vervaardiger, bied ons presisie CNC-draaidienste spesifiek ontwerp vir draagroltoepassings, gekombineer met omvattende aangepaste gietoplossings. Ons geïntegreerde vervaardigingsbenadering lewer draagrolle wat optimale prestasie, verlengde bedryfslewe en betroubare werking in veeleisende industriële omgewings verseker, veral vir konstruksie-, myn- en swaar toerustingtoepassings.

Materiaaluitnemendheid en Prestasie-eienskappe

Ons gebruik hoë-gehalte materiale wat spesifiek gekies is vir draerrol-toepassings, insluitend 4140 legeringstaal en 1045 koolstofstaal vir uitstekende slytasiebestandheid en duursaamheid. Ons sferoïedale ystergrader (65-45-12, 80-55-06) bied uitstekende impaksterkte met treksterktes wat wissel van 448-552 MPa, terwyl dit goeie bewerkbaarheid behou. Vir toepassings wat verbeterde korrosiebestandheid vereis, verskaf ons roestvrye staalvariante (304, 316) wat strukturele integriteit in onherbergbare omgewings handhaaf. Hierdie materiale toon:

Uitstekende hardheid (28-32 HRC vir legeringstowwe)

Uitstekende slytasiebestandheid teen baanslytasie

Hoë impaksterkte vir skokbelastingstoestande

Goed korrosieweerstand in verskillende bedryfomgewings

Bestendige werkverrigting oor temperatuuruiteindes

Gevorderde Vervaardigingsproses

Ons produksiemetodologie integreer presisiegietwerk met gevorderde CNC-draaitegnologie:

Pasgemaakte Gietdienste

Ons gebruik gesofistikeerde gietmetodes, insluitend:

Skuldgiet vir superieure dimensionele akkuraatheid

Harssandgiet vir komplekse geometrieë

Investeringgietery vir kritieke slytvlakke

Beheerde smelt- en gietprosesse

Strategiese ingiet- en loepontwerp

Presisie CNC-draaitegnologie

Ons CNC-draaikapasiteite sluit in:

Meerassige draaibank sentrums met werkende gereedskap

Presisieboor van rolle se interne deursnitte

Geoutomatiseerde draad- en groefwerking

Regstydse deursnitsmonitorsisteme

Geïntegreerde meting en kompensasie

Kwaliteitborging en Prestasievalidasie

Elke draagrol ondergaan streng gehaltebeheer:

Ultrasoon Toetsing vir Interne Defek Detectie

Hardheidsverifikasie oor kritieke oppervlaktes

Dimensionele validasie met behulp van CMM-tegnologie

Oppervlakafwerkingontleding vir optimale digting

Materiaalsertifisering volgens internasionale standaarde

Laai-toetsing onder gesimuleerde bedryfsomstandighede

Industriële Toepassings en Oplossings

Ons draaierollers dien veeleisende toepassings in:

Gesporeerde Toerusting: Graafmasjiene, buldozers en kraalwerktuie

Mynbou-Toerusting: Ondergrondse myntoerusting en oppervlakmyners

Landbou-Toerusting: Gesporeerde traktore en oesmasjiene

Bouvoertuie: Kompakte spoorlaaiers en skidstuurders

Industriële Masjinerie: Materiaalhantering- en vervoerstelsels

Deur gevorderde giettegnologie met presisie CNC-draai-vermoëns te kombineer, lewer ons draaierollers wat betroubare prestasie, verminderde instandhoudingskoste en verlengde diensintervalle bied. Ons ingenieurspan werk nougeset saam met toerustingsvervaardigers om aangepaste oplossings te ontwikkel wat spesifieke toepassingsvereistes bevredig, en sodoende optimale dimensionele akkuraatheid, uitstekende slytasiebestandheid en koste-effektiewe vervaardiging verseker vir beide vervangings- en OEM-toepassings.

Ons Dienste |

Naukeurige CNC-freswerk, Naukeurige CNC-draaiwerk, Vinnige prototipering Plastiek spuitvorm Metaalstempeling, Drukskyfing Silikon- en rubbergootvorm, Aluminiumextrusie, Gootvormvervaardiging, ens. |

Materiaal |

Aluminium Alloy: 5052/6061/6063/7075 ens. Messing Alloy: 3602/2604/h59/h62 ens. Rooiis Alloy: 303/304/316/412 ens. Staal Alloy: Koolstof/Gietstal ens. Ander Spesiale Materialen: Lucite/Nylon/Bakeliet ens. Plastic, Hout, Silicone, Goue, Of soos per die kliënte se vereistes |

Oppervlak Behandeling |

Anodiseren, Sandstraal, Verf, Poederkoting, Elektroplating, Sylk Drukwerk, Borstel, Polier, Lasergraveer... |

Tekening formaat |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl, ens |

Diensprojek |

Om projekontwerp, produksie en tegniese dienste, vormontwikkeling en -vervaardiging, ens te verskaf |

Toetsmasjien |

Digitale hoogtemeter, dividers, Driekoördinatemetingmasjien, projeksie masjien, ruwigheidstester, hardeheidstester en so meer |

Kwaliteitsversekering |

ISO9001:2015 Gertifiseer TUV |

Verpakking |

Skuim, Karton, Houtkasse, of volgens die klant se vereistes |

Lewer |

DHL, FEDEX, UPS, TNT, EMS, SF Of volgens klante se vereiste |