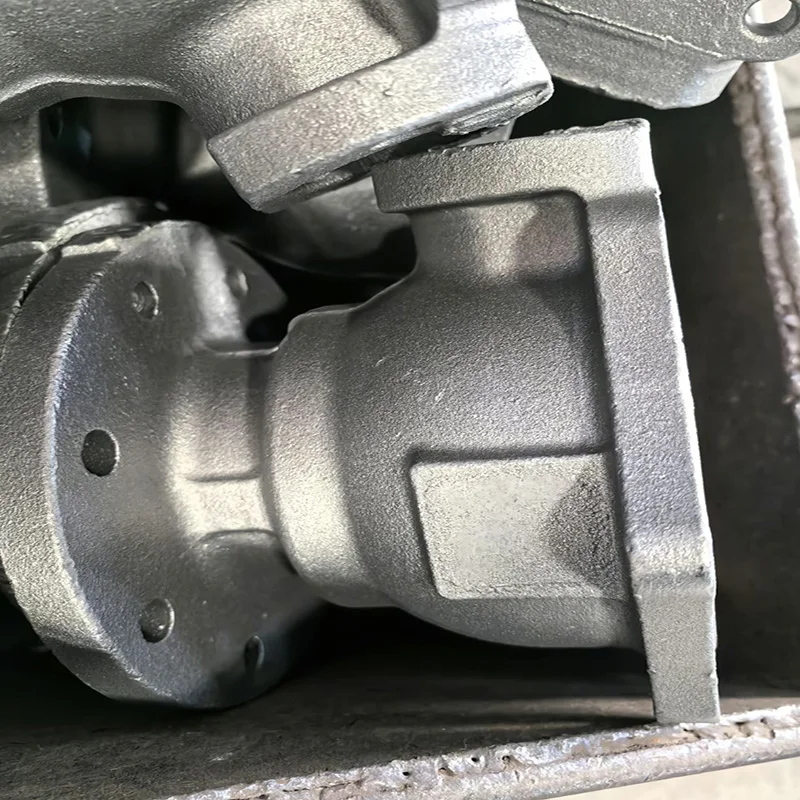

ISO Factory Custom Mirror Polish Stainless Steel Precision Casting Hinge Investment Casting Parts

- Overview

- Recommended Products

In the realm of high-performance metal components, the demand for precision, corrosion resistance, and superior finish is paramount. Our ISO-certified factory specializes in manufacturing custom Stainless Steel Precision Casting Hinge parts, utilizing advanced Investment Casting technology and delivering exceptional Mirror Polish finishes. This integrated service guarantees components that meet the highest standards of dimensional accuracy, structural integrity, and aesthetic appeal.

Material and Inherent Performance

We primarily use 300-series stainless steels, such as SS304 and SS316, for our casting hinges. These alloys are selected for their excellent combination of mechanical properties and corrosion resistance. SS316, with its added molybdenum, offers superior performance in chloride-containing environments, making it ideal for marine or chemical applications. The inherent strength of these materials ensures that our hinges can withstand repeated loading and cyclical stress without failure. The casting process further enhances these properties by producing a homogeneous, fine-grained microstructure, free from the directional weaknesses sometimes found in wrought or machined parts.

Advanced Investment Casting Process

Investment Casting, also known as the lost-wax process, is the core of our manufacturing capability. It is ideal for producing the complex geometries and fine details required for high-quality hinges without the parting lines typical of other casting methods. Our ISO-certified process is meticulous:

Pattern Creation: A precise wax or 3D-printed pattern of the hinge is created.

Shell Building: The pattern is repeatedly dipped in ceramic slurry and stuccoed to build a robust mold.

Dewaxing & Firing: The mold is heated, melting out the wax and leaving a hollow ceramic shell, which is then fired at high temperature.

Pouring and Cooling: Molten stainless steel is poured into the preheated shell and allowed to solidify.

Shell Removal & Finishing: The ceramic shell is broken away, revealing the raw casting, which then undergoes cutting, grinding, and heat treatment if required.

The Mirror Polish Finish and Applications

The final, critical step is the Mirror Polish. This multi-stage process involves progressively finer abrasives to eliminate surface imperfections, achieve a perfectly smooth surface, and produce a brilliant, reflective finish. This is not merely cosmetic; a high-quality polish significantly enhances corrosion resistance by eliminating microscopic sites where pitting could initiate, and it reduces friction on the hinge's pivot points.

These premium hinges are indispensable in numerous demanding sectors:

Medical & Surgical Equipment: For devices, cabinets, and mobile stations requiring smooth operation, hygiene, and cleanability.

Food & Beverage Processing: In machinery where sanitation, resistance to corrosive cleaning agents, and smooth, crevice-free surfaces are mandatory.

Marine & Architectural Hardware: For luxury yachts, buildings, and furniture, providing durability and a high-end aesthetic.

Aerospace & Defense: In instrumentation and control panels where reliability and precision are non-negotiable.

By integrating ISO-controlled investment casting with expert metal finishing, we deliver stainless steel hinge parts that offer unparalleled quality, performance, and longevity for your most critical applications.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |