- Overview

- Recommended Products

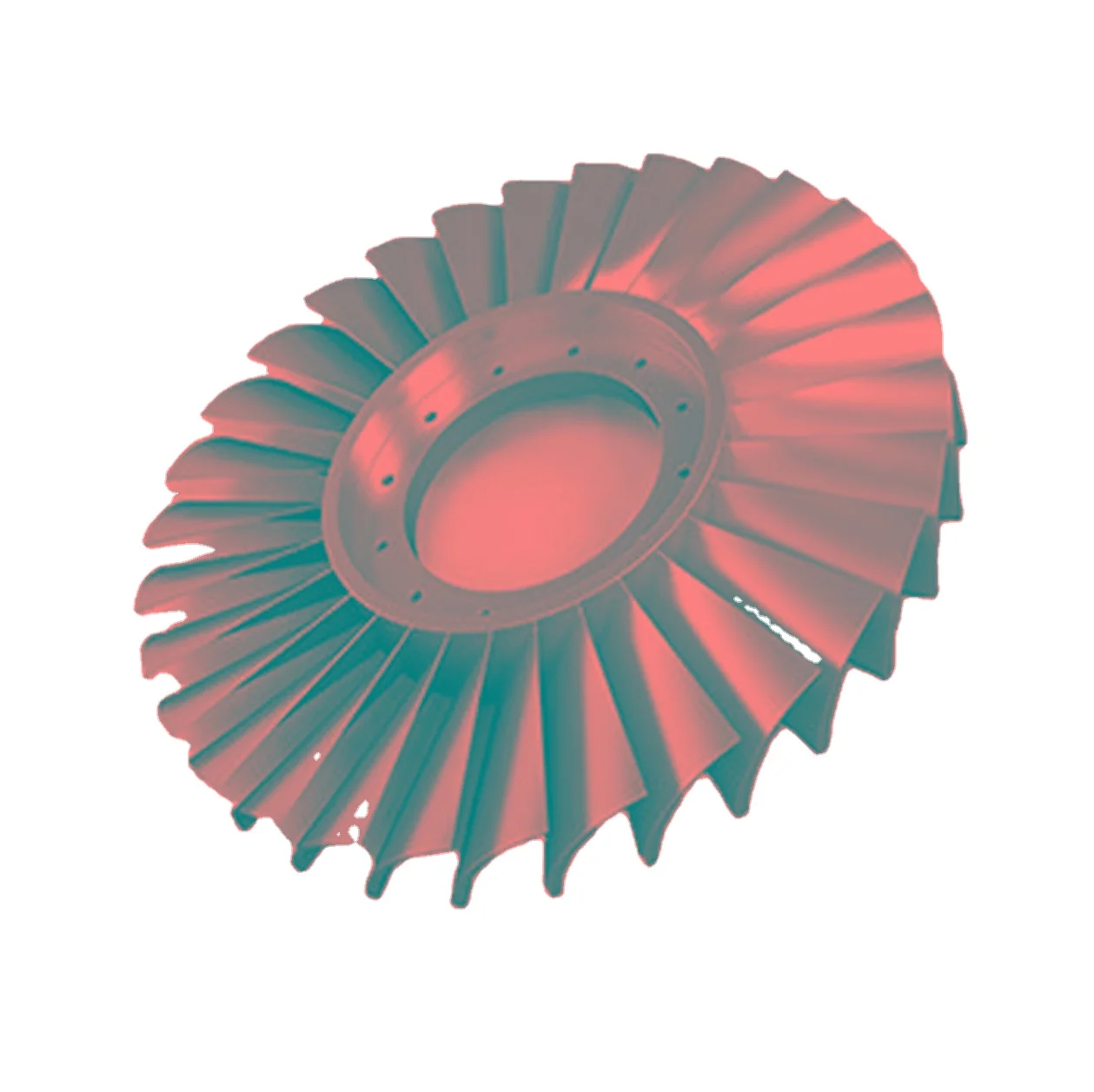

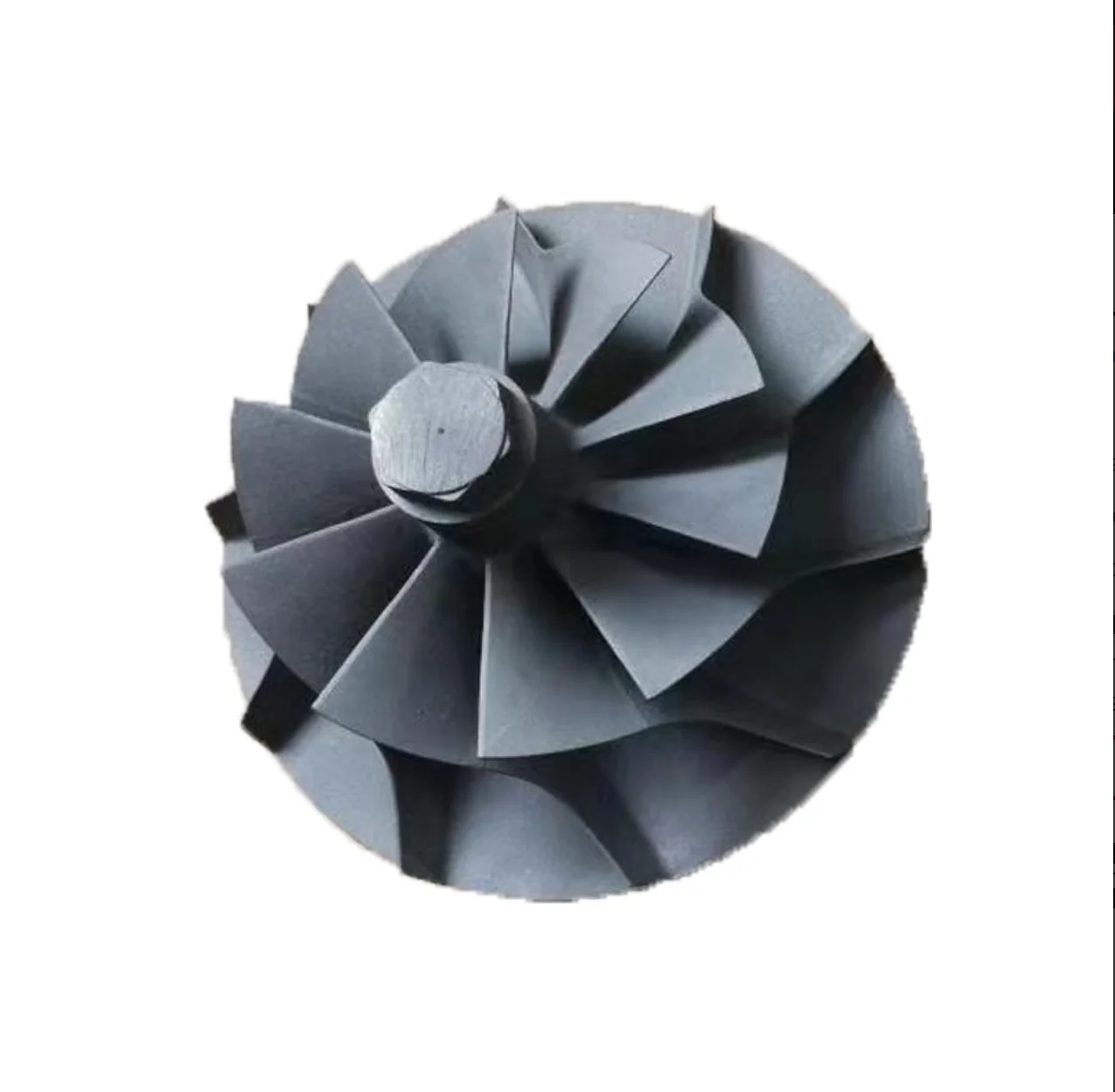

In advanced manufacturing sectors where strength-to-weight ratio, corrosion resistance, and biocompatibility are paramount, titanium components represent the pinnacle of material engineering. Our specialized services combine precision titanium casting with advanced CNC milling and turning operations to deliver components that meet the most demanding specifications across aerospace, medical, and high-performance industrial applications. Through integrated manufacturing approaches, we achieve exceptional dimensional accuracy while maintaining the superior material properties that make titanium indispensable in critical applications.

Advanced Titanium Alloy Selection

We utilize comprehensive titanium grades specifically engineered for precision manufacturing:

Grade 5 (Ti-6Al-4V): The industry workhorse offering excellent strength-to-weight ratio and good fatigue resistance

Grade 2 (Commercially Pure): Superior corrosion resistance and optimal formability for medical applications

Grade 23 (Ti-6Al-4V ELI): Extra-low interstitial grade for enhanced fracture toughness and medical implant applications

Beta Titanium Alloys: Ti-10V-2Fe-3Al and other grades for high-strength applications and improved hardenability

Custom Alloy Formulations: Specialized compositions for specific thermal, mechanical, or chemical requirements

All materials undergo rigorous certification including chemical analysis, mechanical testing, and microstructural examination to ensure compliance with international standards including ASTM, AMS, and ISO specifications.

Precision Manufacturing Process

Our integrated production system ensures exceptional quality throughout manufacturing:

-

Investment Casting Technology

Vacuum arc remelting and vacuum induction melting for superior material quality

Ceramic mold process utilizing zirconia and alumina-based slurries

Hot isostatic pressing (HIP) for elimination of internal porosity

Precision gating systems designed for optimal metal flow and feeding

-

CNC Machining Operations

5-axis simultaneous milling of complex contours and geometries

Precision turning of cylindrical features and bearing surfaces

High-speed machining strategies for optimal surface integrity

Cryogenic machining capabilities for improved tool life and surface finish

-

Heat Treatment and Finishing

Solution treatment and aging for alpha-beta alloys

Stress relieving and annealing processes

Chemical milling and electropolishing operations

Specialized surface treatments including anodizing and thermal spraying

Performance Advantages

Exceptional Strength-to-Weight Ratio: Up to 40% weight reduction compared to steel components

Superior Corrosion Resistance: Excellent performance in aggressive chemical and marine environments

High Temperature Capability: Maintains mechanical properties at elevated temperatures

Excellent Biocompatibility: Ideal for medical implants and surgical instruments

Outstanding Fatigue Resistance: Superior performance under cyclic loading conditions

Quality Assurance Protocol

NADCAP accredited heat treatment and chemical processing

AS9100 and ISO 13485 certified quality systems

First article inspection with comprehensive documentation

Non-destructive testing including FPI, RT, and UT

Complete material traceability from mill to finished part

Statistical process control throughout manufacturing

Technical Applications

Aerospace: Structural components, engine parts, landing gear elements

Medical: Surgical implants, instrument components, diagnostic equipment

Defense: Armor components, weapon systems, vehicle parts

Industrial: Chemical processing equipment, marine components, racing parts

Energy: Turbine blades, heat exchangers, downhole tools

Our engineering team provides comprehensive design-for-manufacturability analysis, ensuring optimal performance while maximizing production efficiency. We maintain complete traceability and documentation throughout the manufacturing process, with particular emphasis on aerospace and medical industry requirements. Contact our technical specialists today to discuss your titanium component requirements and discover how our integrated casting and machining capabilities can provide innovative solutions for your most challenging applications.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |