- Overview

- Recommended Products

Premium Protection for Electric Motors

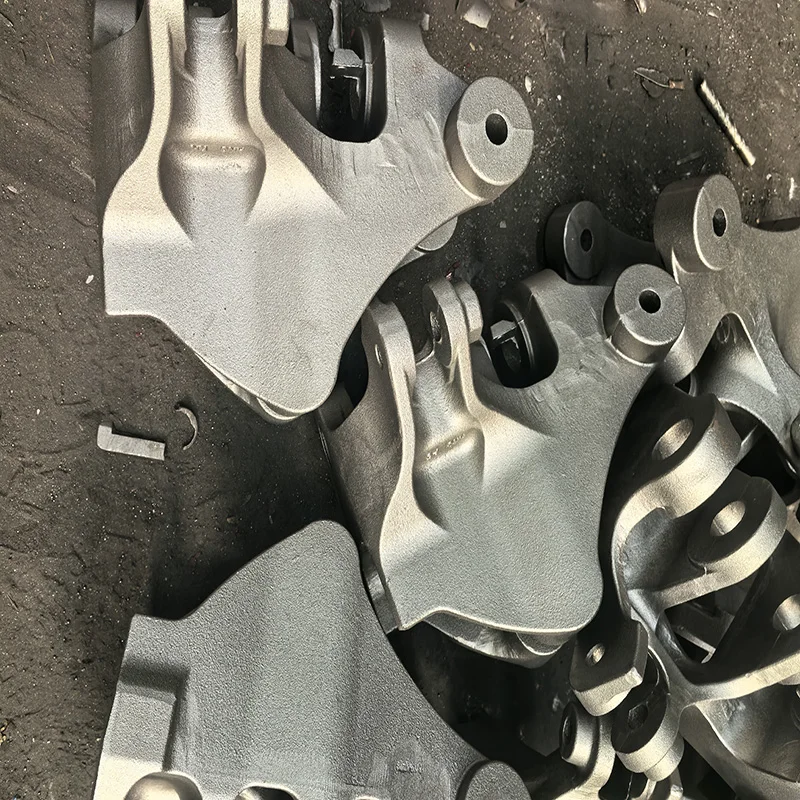

Our cast iron shell casting motor end covers provide superior protection and structural integrity for electric motors across industrial applications. Utilizing advanced shell molding technology, we manufacture precision end covers that ensure optimal alignment, effective sealing, and reliable performance in demanding operational environments.

Advanced Material Specifications

We employ high-grade cast iron materials specifically engineered for motor applications:

Gray Iron (GG25/G3000): Delivering excellent vibration damping and thermal conductivity

Ductile Iron (GGG40/400-18): Providing enhanced strength and impact resistance

Compacted Graphite Iron: Offering superior thermal fatigue resistance

All materials undergo rigorous metallurgical testing to ensure consistent microstructure and mechanical properties meeting international ASTM standards.

Enhanced Performance Characteristics

Our motor end covers demonstrate exceptional operational capabilities:

Superior vibration damping capacity (5-10 times higher than steel)

Excellent thermal conductivity (45-50 W/m·K) for efficient heat dissipation

High compressive strength (600-800 MPa) maintaining structural integrity

Good machinability for precise bearing seat and mounting hole accuracy

Corrosion resistance suitable for various industrial environments

Pressure tightness ensuring effective sealing against contaminants

Precision Shell Casting Process

Our manufacturing process ensures dimensional accuracy and quality:

Pattern Development:

CNC-machined metal patterns with precise draft angles

Thermal expansion compensation in pattern design

Surface finish maintained at Ra 3.2 μm or better

Shell Mold Production:

Resin-coated sand with optimal binder distribution

Automated mold making ensuring consistent shell thickness

Controlled curing process for maximum mold strength

Casting Operations:

Precision pouring temperature control (±15°C)

Automated gating systems minimizing turbulence

Controlled solidification preventing shrinkage defects

Real-time process monitoring and documentation

Quality Assurance Protocol

Each end cover undergoes comprehensive validation:

Dimensional inspection using CMM systems

Ultrasonic testing for internal integrity

Surface roughness measurement

Bearing seat concentricity verification

Pressure testing for sealing applications

Industrial Applications

Industrial AC/DC motors and generators

Pump motors and compressor drives

Agricultural motor applications

HVAC system motors

Automotive traction motors

Technical Specifications

Size range: 50mm to 800mm diameter

Wall thickness: 4mm to 25mm

Weight capacity: Up to 50kg per unit

Dimensional tolerance: CT8 to CT10 per ISO 8062

Surface finish: Ra 12.5 to 25 μm as-cast

Competitive Advantages

30+ years of specialized motor component experience

Complete in-house pattern making capability

Flexible production volumes from prototypes to mass production

Technical support for design optimization

Full material traceability and certification

Our shell casting expertise combined with rigorous quality control ensures motor end covers that provide reliable protection and precise alignment for electric motors. The superior damping characteristics of our cast iron components significantly reduce noise and vibration, while the excellent machinability allows for precise bearing fits and mounting surfaces, ensuring long-term operational reliability in diverse industrial applications.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |