- סקירה

- מוצרים מומלצים

הגנה מתקדמת על מנועים חשמליים

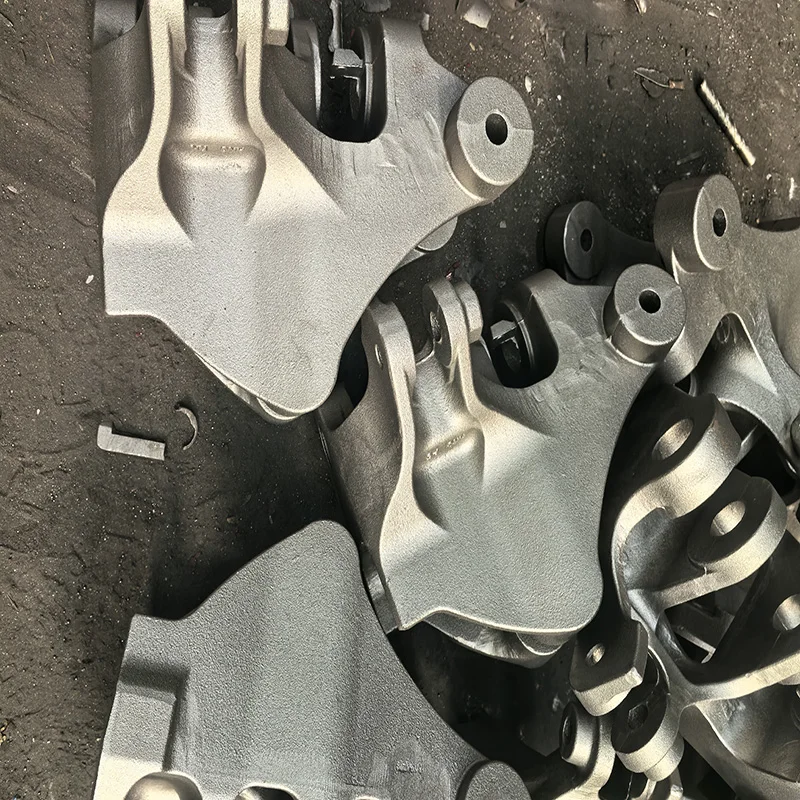

כיסויי הקצה שלנו מפלדת יצוקה מספקים הגנה ויציבות מבנית גבוהה למוסות חשמליים בתחומים תעשייתיים. בעזרת טכנולוגיית ייצור מתקדמת, אנו מייצרים כיסויי קצה מדויקים שמבטיחים יישור אופטימלי, החדרה יעילה וביצועים אמינים בסביבות עבודה קשות.

מפרטים מתקדמים של החומר

אנו משתמשים בחומרי פלדה יצוקה איכותיים, מעוצבים במיוחד לשימוש במנועים:

פלדה אפורת (GG25/G3000): מספקת דämpינג רטט מצוין ו מוליכות תרמית גבוהה

פלדה דקטילית (GGG40/400-18): מספקת חוזק משופר ועמידות בפני מכות

פלדה גרפיטית דחוסה: מספקת עמידות מוגברת בפני עייפות תרמית

כל החומרים עוברים בדיקות מתלורגיות קפדניות כדי להבטיח מיקרו-מבנה ותכונות מכניות עקביות, בהתאם לתקני ASTM הבינלאומיים.

מאפיינים של ביצועים מוגברים

כיסויי הקצה של המנוע שלנו מציגים יכולות תפעול יוצאות דופן:

יכולת דämping גבוהה במיוחד של רעדים (5-10 פעמים יותר גבוהה מפלדה)

מוליכות חום מעולה (45-50 וואט/מטר•קלווין) לפיזור חום יעיל

חוזק לחיצה גבוה (600-800 מ"פ) שמור על שלמות המבנית

נאות עיבוד טובה לצורך דיוק מדויק במושב השעון ובנקודות החיבור

עמידות בפני קורוזיה מתאימה לסוגי סביבות תעשייתיות שונים

אטימות לחץ שמונעת חדירת זיהומים

תהליך הזרקה מדויק של קליפה

תהליך הייצור שלנו מבטיח דיוק ממדי ואיכות:

פיתוח תבנית:

דפוסי מתכת עטופי CNC עם זוויות הוצאה מדויקות

השלמת הרחבה תרמית בעיצוב הדפוס

גימור משטח נשמר ברמה Ra 3.2 μm או טוב יותר

ייצור קליפות:

חול מצופה רזין עם הפצה אופטימלית של חומר מחזק

יצירת תבנית אוטומטית המבטיחה עובי קליפה אחיד

תהליך עיבוד מבוקר לחוזק תבנית מרבי

תהליכי יציקה:

בקרת טמפרטורת יריקה מדויקת (±15°C)

מערכות שסתומים אוטומטיות שמפחיתות טורבולנציה

התמצקות מבוקרת המונעת פגמי כיווץ

ניטור והרשמה בזמן אמת של התהליך

פרוטוקול הבטחת איכות

כל כיסוי קצה עובר אימות מקיף:

בדיקת ממדים באמצעות מערכות CMM

בדיקה אולטראסונית לאיכות פנימית

מדידת גסות פני השטח

אימות ריכוזיות של ישיבתแบรינג

בדיקת לחץ ליישומי החסימה

יישומים תעשייתיים

מוטורים תעשייתיים לזרם חילופין/יושר

מוטורי משאבות ומניעים לקומפרסורים

יישומי מנועים חקלאיים

מנועים למערכות קירור וחימום (HVAC)

מנועי גרירה לרכב

מפרטים טכניים

טווח גודל: קוטר 50 מ"מ עד 800 מ"מ

עובי דופן: 4 מ"מ עד 25 מ"מ

קיבולת משקל: עד 50 ק"ג ליחידה

סיבולת ממדים: CT8 עד CT10 לפי ISO 8062

גימור משטח: Ra 12.5 עד 25 מיקרומטר, כפי שנזרק

יתרונות תחרותיים

מעל 30 שנות ניסיון בתחום רכיבי מנועים

יכולת ייצור תבניות מלאה בתוך בית

נפחי ייצור גמישים, מהפרוטוטיפ עד ייצור המוני

תמיכה טכנית לאופטימיזציה של עיצוב

עקיבות מלאה של חומרים ואישורים

המומחיות שלנו ביציקת מעטפת בשילוב עם בקרת איכות קפדנית מבטיחים כיסויי קצה למנוע המספקים הגנה אמינה ויישור מדויק למנועים חשמליים. מאפייני הריסון המעולים של רכיבי הברזל היצוק שלנו מפחיתים משמעותית את הרעש והוויברציות, בעוד שיכולת העיבוד המצוינת מאפשרת התאמת מיסבים ומשטחי הרכבה מדויקים, מה שמבטיח אמינות תפעולית לטווח ארוך ביישומים תעשייתיים מגוונים.

חומר |

פלדה, פלדה נקיה, אלומיניום, ברזל, פלדה קARBON, נחושת, צהוב, ליגת, וכו'. |

עובי |

0.1mm עד 12mm, לפי בקשתך |

גדלים |

1) לפי תבליטי לקוחות' 2) לפי דגמי לקוחותomers |

טיפול שטח |

אנודיזציה, גלובזים, צינק, ניקל, כרום, קוטר פולימרי, ציור, וכו'. |

פורמט ציור |

DWG, DXF, STEP, STP, STL, AI, PDF, JPG, טיוטה. |

אריזה |

כיס פוליאסטר+תיבה של קרטון+מקרה עץ/פלט, לפי בקשת הלקוח |

משלוח |

1) על ידי משלוח מהיר, כמו DHL, TNT, Fedex, וכו', בדרך כלל 5-7 ימים כדי להגיע |

2) באוויר למשתל איר, בדרך כלל, 3-4 ימים כדי להגיע |

|

3) דרך נמל ים, בדרך כלל 15-30 ימים כדי להגיע |

|

זמן מסירה |

תלוי בכמויות, בדרך כלל כ-20 ימים. |

תנאי תשלום |

T/T, פאייפאל, Trade Assurance |

הסמכה |

ISO |

שירות לוגו |

מסופק |

שימוש |

משתמשים בהרבה תחומים בבנייה, תעשייה, ותעשיית רכב. |