- Overview

- Recommended Products

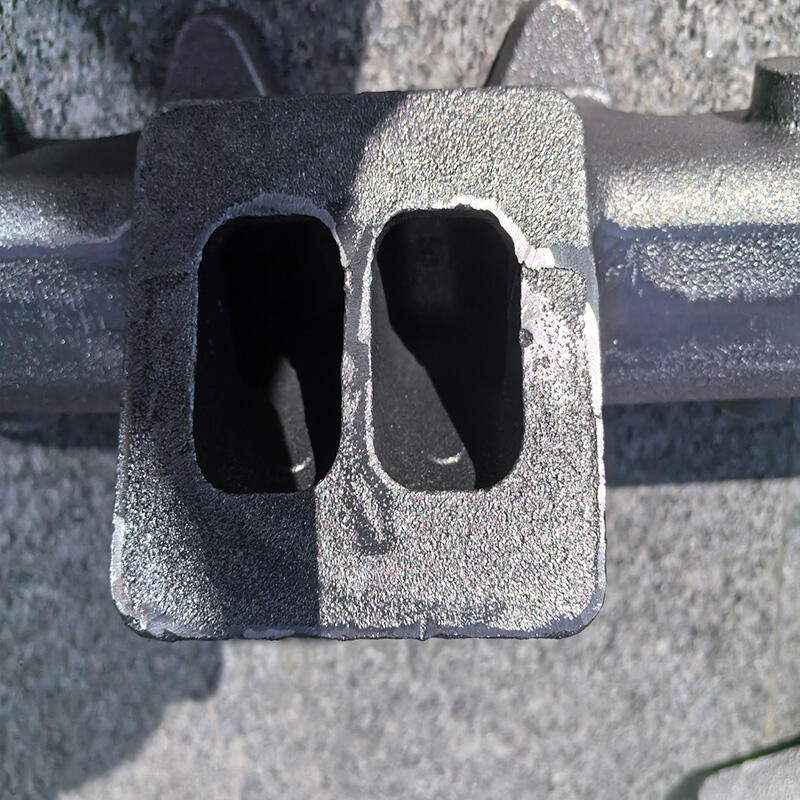

Introducing, the Pengxin Customized China OEM Automotive Stainless Steel Turbo Exhaust Manifold Sand Casting Parts, the perfect solution for anyone looking to upgrade their vehicle's performance and durability. Made from high-quality stainless steel, these parts are designed to withstand the toughest conditions and provide optimal performance for your vehicle.

Designed and manufactured by Pengxin, a trusted brand in the automotive industry, these custom exhaust manifold parts are specifically engineered to improve the overall performance of your vehicle. The sand casting process ensures for a precise fit and finish, guaranteeing that these parts will seamlessly integrate into your vehicle's exhaust system.

Whether you are looking to boost your vehicle's horsepower, torque, or overall efficiency, these stainless steel turbo exhaust manifold parts are the ideal choice. They are designed to withstand high temperatures and extreme conditions, making them suitable for use in a wide range of vehicles, including cars, trucks, and SUVs.

In addition to their durability and performance benefits, these parts are also customizable to meet your specific needs. Whether you need a specific size, shape, or finish, Pengxin can work with you to create the perfect exhaust manifold parts for your vehicle. This level of customization ensures that you get the exact parts you need to optimize your vehicle's performance and ensure a perfect fit.

Installing these custom exhaust manifold parts is easy and straightforward, thanks to their precision engineering and high-quality construction. Simply replace your existing exhaust manifold with these parts, and enjoy the immediate improvements in your vehicle's performance and efficiency.

The Pengxin Customized China OEM Automotive Stainless Steel Turbo Exhaust Manifold Sand Casting Parts are the perfect choice for anyone looking to upgrade their vehicle's exhaust system. With their high-quality construction, durability, and performance benefits, these parts are sure to enhance your driving experience and give your vehicle the edge it needs to perform at its best. Upgrade your vehicle with Pengxin today and experience the difference for yourself

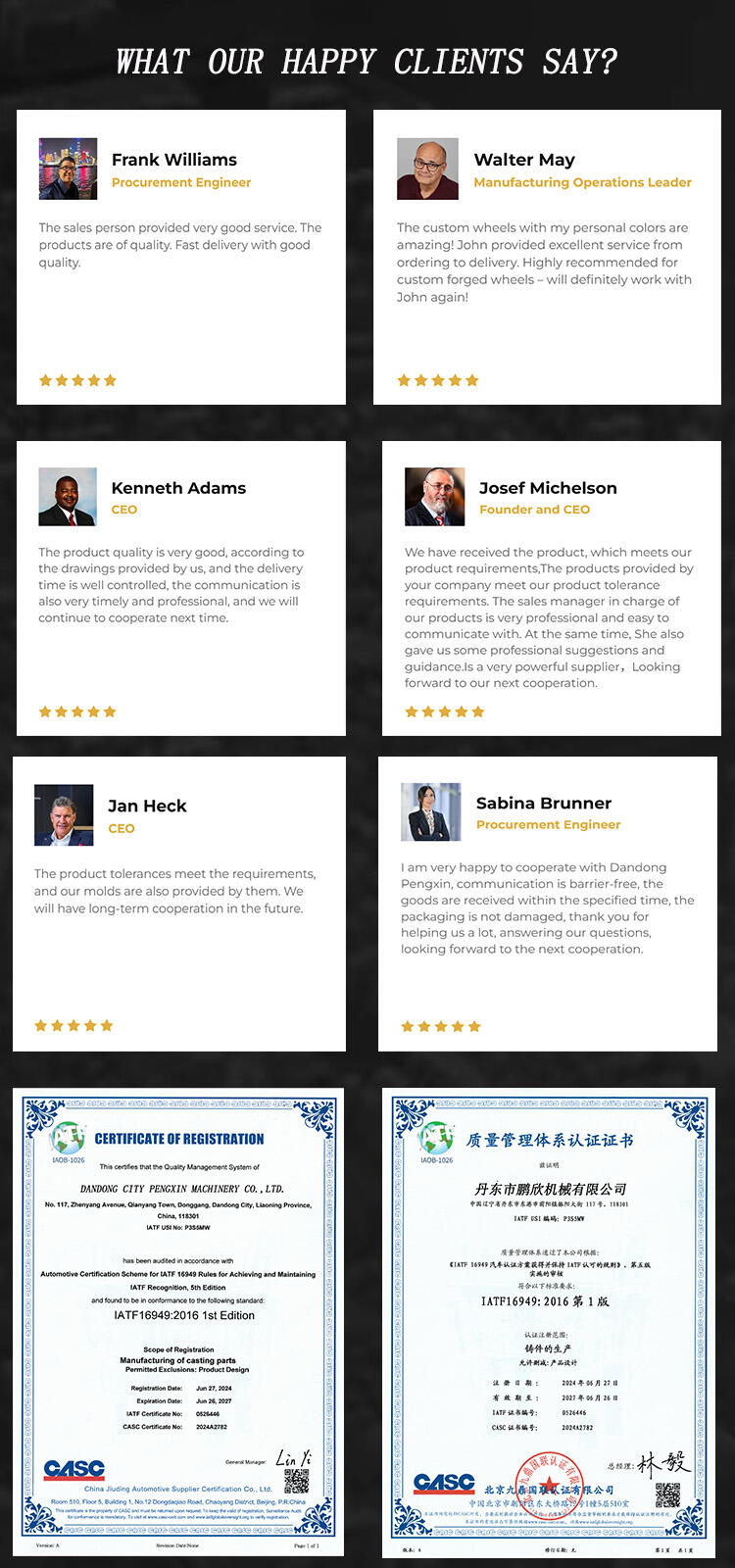

Dandong Pengxin Machinery Co., Ltd., founded in 1958, is a private enterprise specializing in casting, machining, and assembly. Spanning 66,000 m² with 40,000 m² of workshops, it has $40M in assets and 330 employees, including 46 technical staff. Annual capacity reaches 100,000 tons

Equipped with advanced technologies like high-pressure molding and Japanese FBO Ⅲ production lines, it produces up to 30,000 tons/year. Facilities include 12-pulse electronic furnaces, CNC machines, and a quality inspection center with precision instruments

Pre-sales

On Sale

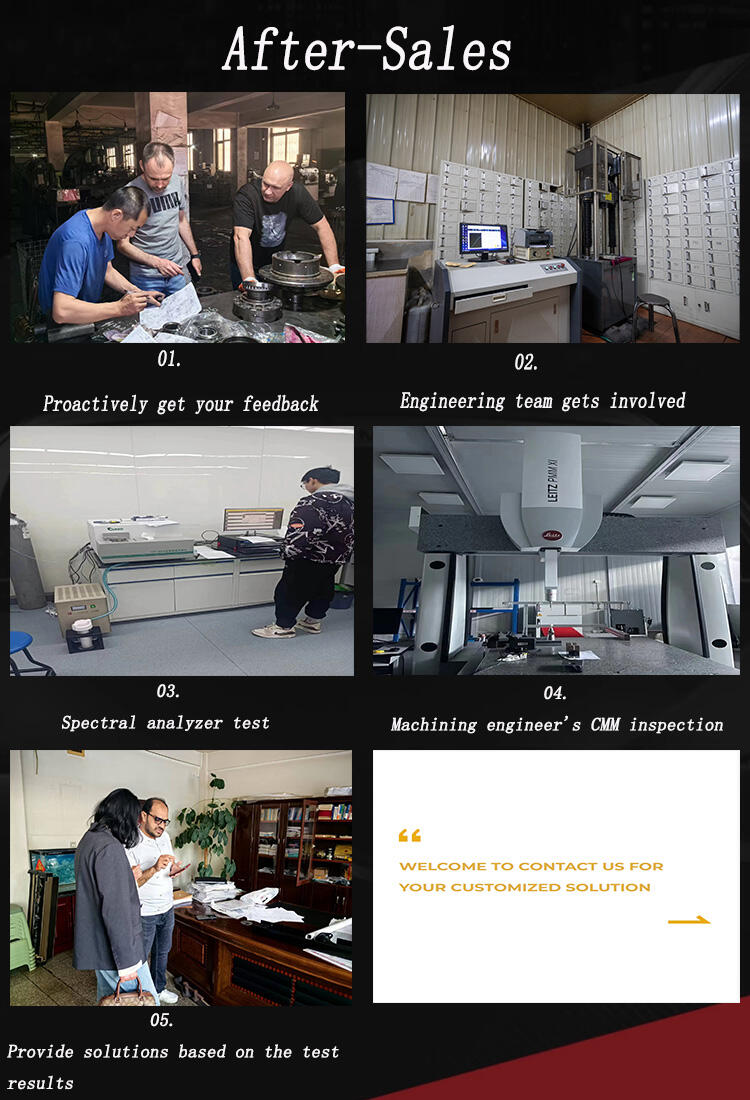

After-Sales

results→Welcome to contact us for your customized solution

How did Dandong Pengxin Become a Top Manufacturer of Exhaust Manifold

To become a world-leading exhaust manifold producer, Dandong Pengxin Machinery introduced in advanced manufacturing technologies, material innovation, quality control, and supply chain efficiency. Below are the key strategies to achieve this goal

1. Advanced Casting Technologies

(1) High-Precision Casting ProcessesResin-Coated Sand Casting (Main production materials are gray cast iron and ductile iron)

Ensures thin-wall, complex geometries with excellent surface finish (Ra 6.3–12.5 μm). Ideal for high-performance exhaust manifolds with tight tolerances.(2) Investment Casting - Main production materials are 316 Stainless Steel and Heat-resistant steelUsed for premium turbine housings and racing exhaust components, especially for some freight trucks in the United States

(3) Gravity Casting for Aluminum Manifolds

Lightweight solutions for hybrid/electric vehicle exhaust systems, Gravity casting is the preferred method for mass-producing exhaust manifolds, involving melting metals like cast iron or aluminum and pouring the molten material into preheated steel molds solely by gravitational force. The process naturally fills mold cavities without external pressure, though some advanced variants may apply minimal supplemental pressure (0.2-0.5 bar) for complex geometries. This cost-effective method yields components with uniform 3-6mm wall thicknesses and smooth surfaces, offering superior metallurgical integrity and higher production rates than sand casting, making it ideal for durable exhaust systems requiring consistent quality in high volumes

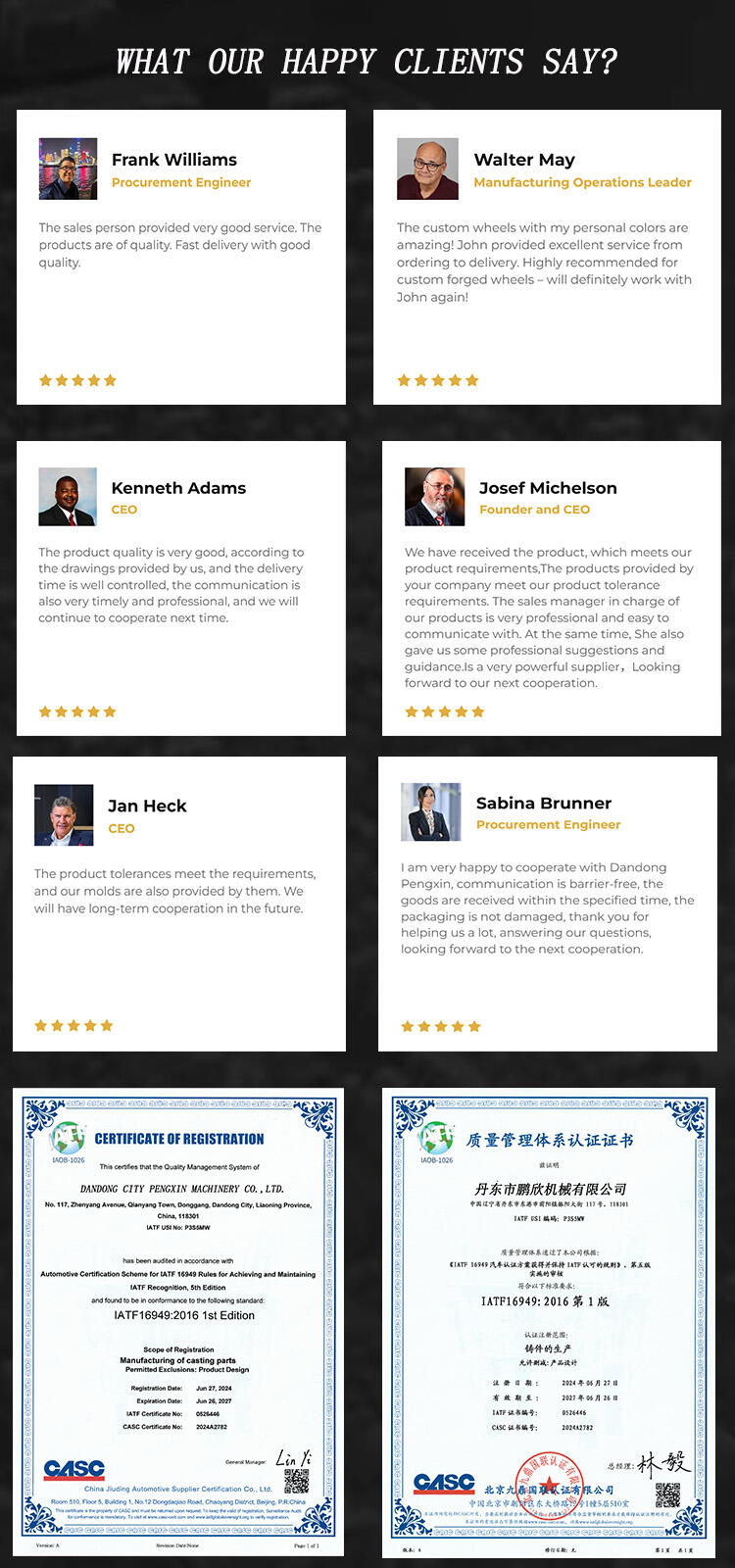

2. Quality & Certification StandardsISO 9001/TS 16949 (IATF 16949) → Automotive quality compliance Leak & Pressure Testing → Ensures 100% gas-tight manifolds Thermal Cycling Tests → Simulates 10+ years of thermal fatigue 3D Scanning & CMM Inspection → Validates dimensional accuracy - ±0.1mm

R&D

R&D

Our Company Owns A Provincial Level Technology Center, Plus A 15 Person R&D Team, With average 20+ Years Of R&D Experience. We can help customers design for free according to their requirements, or produce according to the drawings or samples

Production Capacity

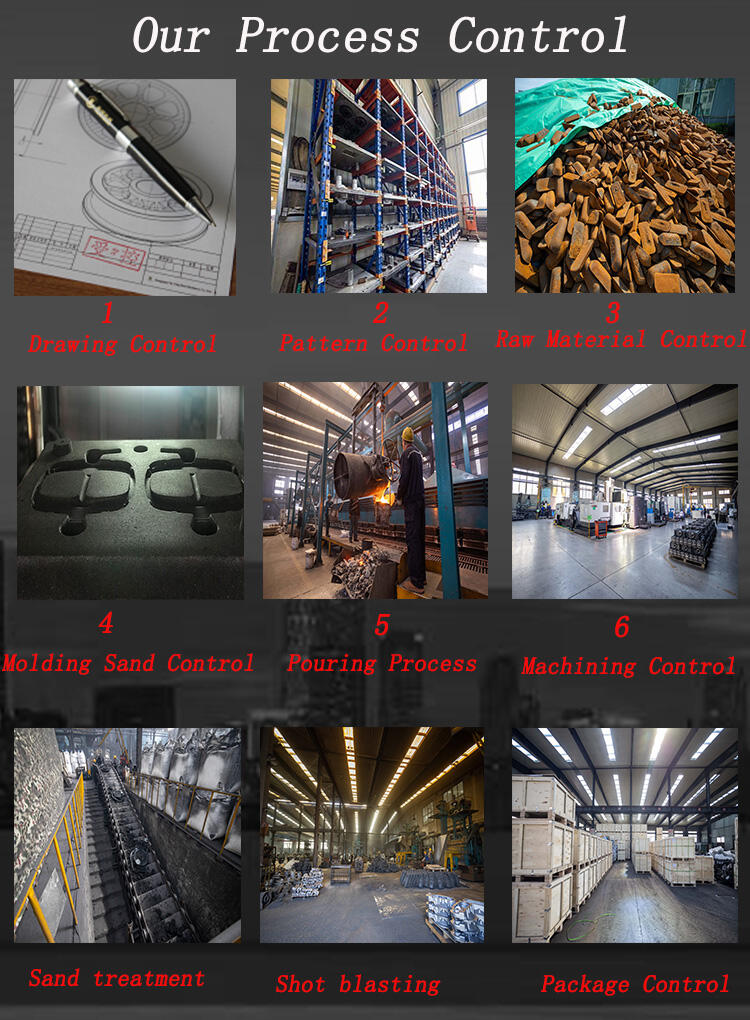

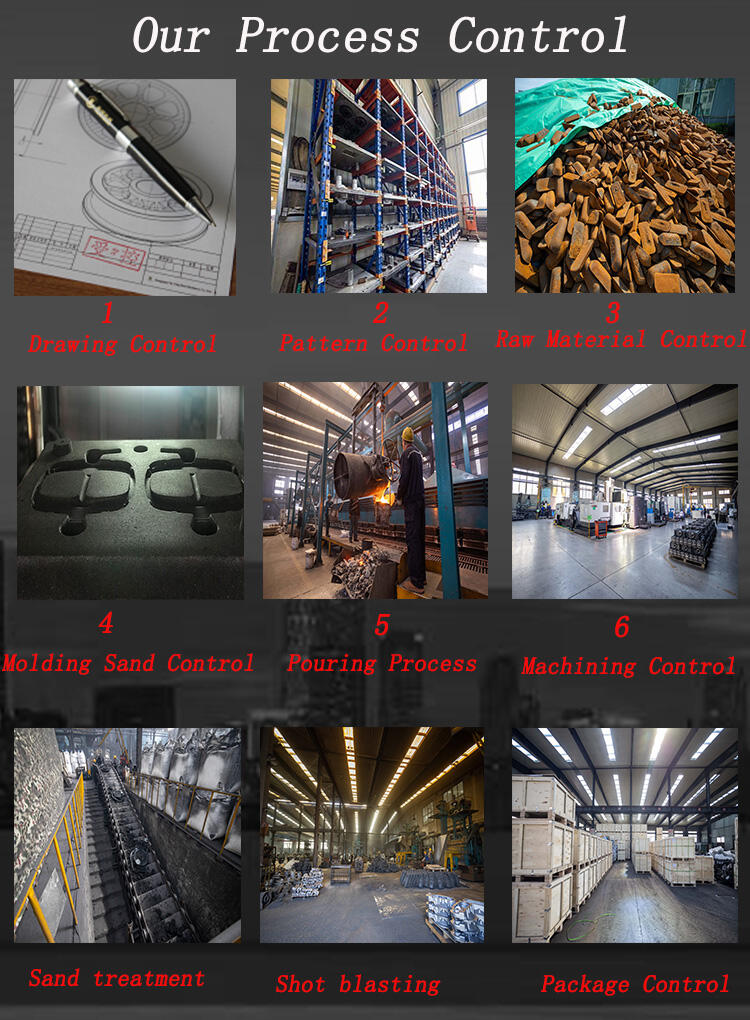

At Pengxin-Casting, process control begins as early as in the planning and development phase of the products. We support our customers to perform all required tests and inspections in a laboratory. It goes without saying that our plants are certified according to ISO 9001 and IATF16949 in line with a validated quality management. As we strive to accomplish our zero-error policy, you can rely on the following process control measures: Drawing Control → Pattern Control → Raw Material Control → Molding Sand Control → Pouring Process Control → Raw Casting & Machining Control →Other Requirement Control→ Packing & Delivery Control

Dandong Pengxin Foundry - Your Trusted Casting Solutions Partner Backed by 67+ years of metallurgical expertise, we deliver precision castings including exhaust manifolds and turbo housings through advanced resin-coated sand and gravity casting technologies. Our 50,000-ton capacity facility features automated molding machines, robotic shell production, and spectral analysis for quality assurance, serving global automotive and industrial clients with IATF 16949-certified manufacturing. Specializing in thin-wall (3-6mm) castings with Ra12-25μm finishes, our engineering team develops optimized solutions from prototype to mass production, supported by in-house mold design and rapid sample development within 15 days

Dandong Pengxin Foundry - Your Trusted Casting Solutions Partner Backed by 67+ years of metallurgical expertise, we deliver precision castings including exhaust manifolds and turbo housings through advanced resin-coated sand and gravity casting technologies. Our 50,000-ton capacity facility features automated molding machines, robotic shell production, and spectral analysis for quality assurance, serving global automotive and industrial clients with IATF 16949-certified manufacturing. Specializing in thin-wall (3-6mm) castings with Ra12-25μm finishes, our engineering team develops optimized solutions from prototype to mass production, supported by in-house mold design and rapid sample development within 15 days

Our Company Owns A Provincial Level Technology Center, Plus A 15 Person R&D Team, With average 20+ Years Of R&D Experience. We can help customers design for free according to their requirements, or produce according to the drawings or samples

Production Capacity