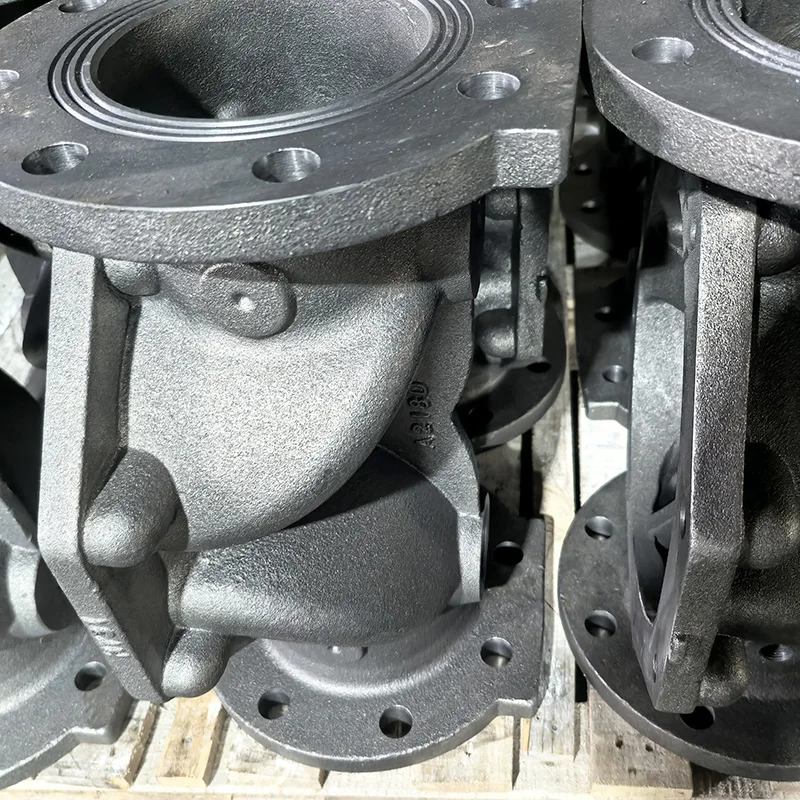

In critical fluid control systems across industrial sectors, the valve body serves as the fundamental pressure boundary determining operational safety and longevity. Our heavy-duty steel valve bodies, manufactured through advanced sand casting processes, provide robust solutions for globe valves, check valves, and gate valves operating in demanding service conditions. These components form the structural core of fluid handling systems where reliability under high pressure and temperature extremes is non-negotiable.

Material Excellence and Performance Characteristics

We utilize premium carbon steel grades (WCB, LCB, WCC) and low-alloy steels (WC6, WC9) specifically engineered for valve applications in demanding environments. Our standard WCB carbon steel delivers minimum tensile strength of 485 MPa, yield strength of 250 MPa, and excellent impact resistance at service temperatures from -29°C to 425°C. For elevated temperature applications, WC6 and WC9 chromium-molybdenum steels maintain mechanical integrity up to 593°C with enhanced creep resistance. The sand casting process ensures homogeneous grain structure with minimal shrinkage porosity, significantly improving pressure retention capabilities and fatigue resistance through repeated cycling. All materials demonstrate exceptional resistance to thermal shock and mechanical stress, with pressure ratings spanning 150 through 2500 classes.

Precision Sand Casting Manufacturing Process

Our manufacturing employs advanced resin sand casting technology with automated molding systems that maintain dimensional stability within ±0.002 inches per inch for complex valve body geometries. The process begins with simulation-optimized pattern equipment designed to achieve optimal feeding and solidification characteristics. Controlled pouring in climate-regulated foundry environments ensures complete mold filling and sound metallurgical structure. Each valve body undergoes comprehensive heat treatment including normalizing, quenching, and tempering to achieve specified mechanical properties and microstructures. Precision machining on CNC boring mills and machining centers follows, maintaining bore tolerances within IT8 standards and surface finishes of 3.2 μm Ra for critical sealing surfaces, ensuring perfect compatibility with trim components and gasket surfaces.

Comprehensive Industrial Applications

Our heavy-duty valve bodies serve critical functions across multiple high-pressure industries including oil and gas transmission (API 6D specifications), power generation (ASTM A216 standards), chemical processing (NACE MR0175 compliance), and water treatment systems. The robust construction withstands aggressive media including steam, hydrocarbons, corrosive chemicals, and abrasive slurries. Our manufacturing capabilities accommodate various end connections including flanged (ANSI B16.5), butt-weld (ANSI B16.25), and socket-weld configurations, with customized designs available for specific operating parameters and actuation requirements.

Partner with our manufacturing expertise for heavy-duty steel valve bodies that combine metallurgical excellence with precision engineering. Our sand casting technology delivers components that enhance valve service life, reduce maintenance costs, and ensure reliable performance in the most demanding fluid control applications, supported by comprehensive quality certification including pressure testing, material verification, and dimensional inspection reports.

About Us