- Overview

- Recommended Products

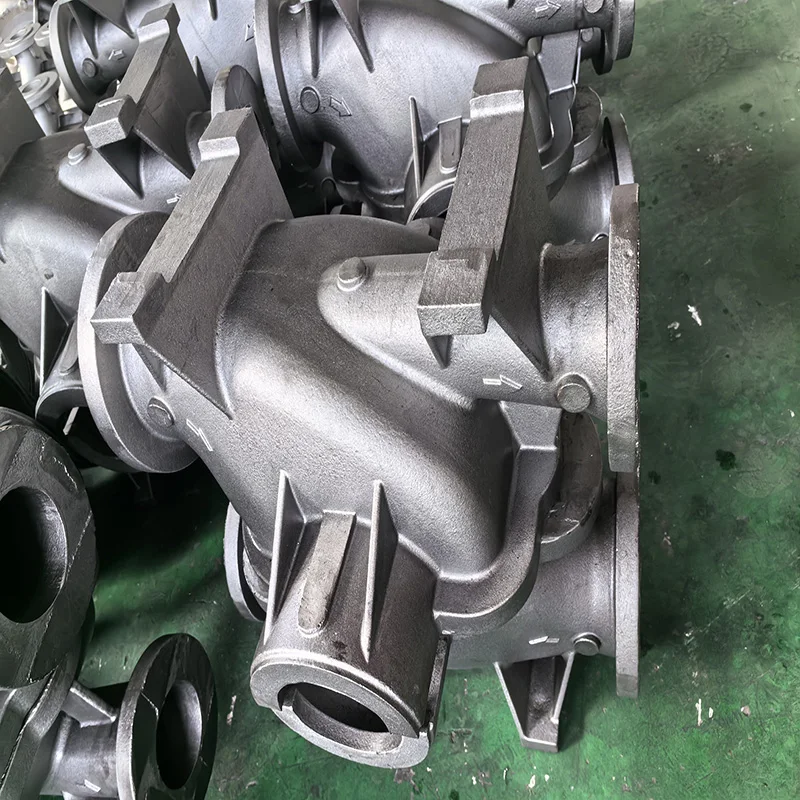

As a specialized manufacturer in industrial components, we provide custom pump housing solutions through advanced sand casting and shell molding technologies. Our iron casting services combine material expertise with precision manufacturing to deliver pump housings that ensure superior performance, durability, and reliability in demanding industrial applications.

Material Excellence and Performance Characteristics

We utilize high-grade grey iron and ductile iron specifically engineered for pump housing applications. Our grey iron grades (G25-G35) offer excellent vibration damping capacity and superior wear resistance, with tensile strength ranging from 250-350 MPa and compressive strength 3-4 times higher. For applications requiring enhanced mechanical properties, we provide ductile iron (Grades 65-45-12) with tensile strength of 448 MPa and elongation of 12-15%. These materials demonstrate exceptional corrosion resistance, pressure tightness, and maintain dimensional stability under thermal cycling conditions typical in pump operations.

Advanced Manufacturing Process

Our production methodology integrates two complementary casting technologies:

Sand Casting Technology

We employ both green sand and resin sand molding systems that enable:

Production of large, complex housing geometries

Consistent wall thickness maintaining structural integrity

Superior surface finish reducing turbulence

Cost-effective manufacturing for various batch sizes

Shell Molding Precision

Our shell molding capabilities deliver:

Exceptional dimensional accuracy (±0.13mm per 25mm)

Excellent surface finish (Ra 3.2-6.3 μm)

Reduced machining allowances and material waste

Consistent reproduction of intricate details

Quality Assurance and Performance Validation

Each pump housing undergoes rigorous quality control:

Pressure testing to 150% of rated working pressure

Ultrasonic inspection for internal integrity

Coordinate measuring machine dimensional verification

Material composition analysis using spectrometry

Mechanical property testing confirming specifications

Application-Specific Engineering

Our pump housings serve diverse industrial sectors:

Water Treatment Plants: Corrosion-resistant housings for chemical pumps

Oil and Gas Industry: High-pressure housings for extraction pumps

Manufacturing Facilities: Durable housings for process pumps

Marine Applications: Saltwater-resistant pump components

Agricultural Systems: Robust housings for irrigation pumps

By combining advanced sand casting and shell molding technologies with comprehensive quality assurance, we deliver pump housings that provide reliable performance, extended service life, and optimal efficiency. Our engineering team collaborates closely with clients to develop customized solutions that meet specific application requirements, ensuring perfect fitment, superior performance, and cost-effective manufacturing for industrial pump applications worldwide.

Product Name |

casting parts/Die Casting Parts/sand casting part/aluminum die casting parts |

Casting Service |

Die Casting, Sand Casting, Gravity Casting, etc. |

Material |

QT200, 250,HT250, Aluminum ADC12, etc (Aupon your requirements.) |

Tooling Design |

We have own R&D team to make customized tooling, usually 7-15days can be ready. |

Standard |

China GB high precision standard. |

Surface Finish |

Mill Finishing, Anodizing, Powder coating, Wood grain, Polishing, Brushing, Electrophoresis. |

Drawing |

3D Drawing: .step / .stp, 2D Drawing: .dxf/ .dwg / .pdf |