- Overview

- Recommended Products

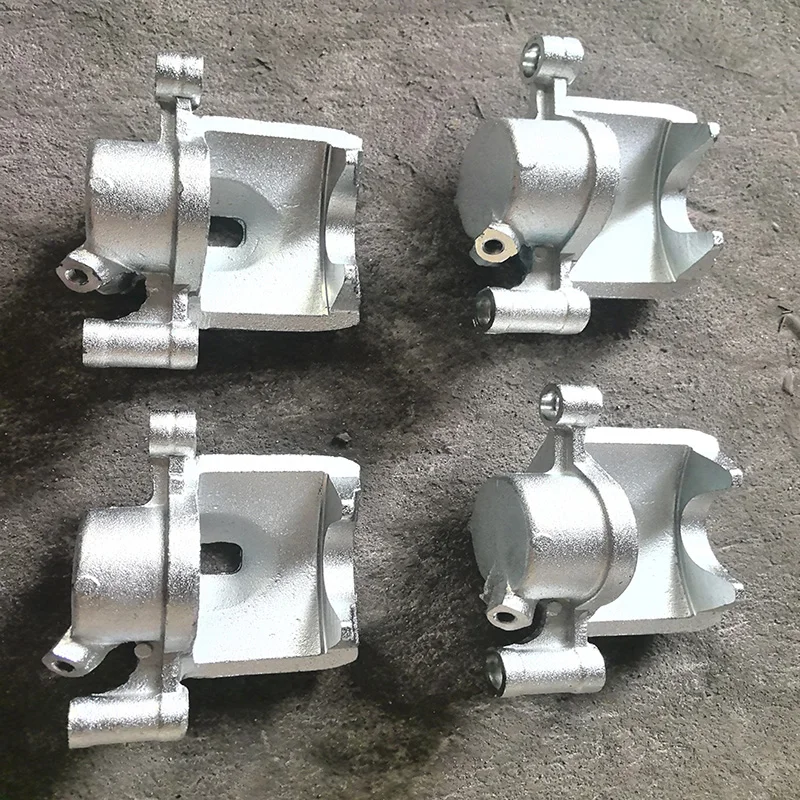

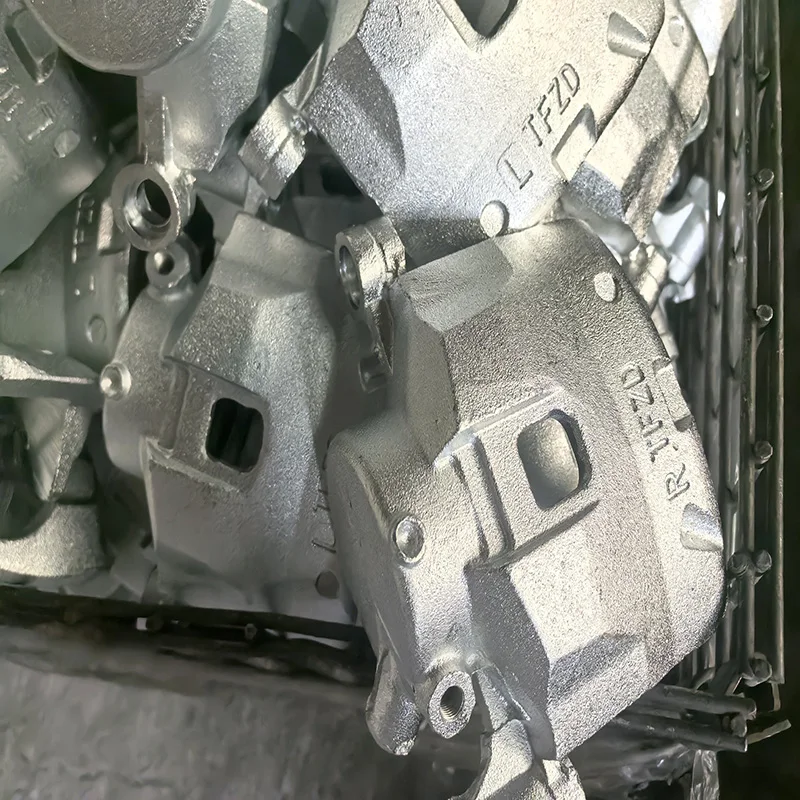

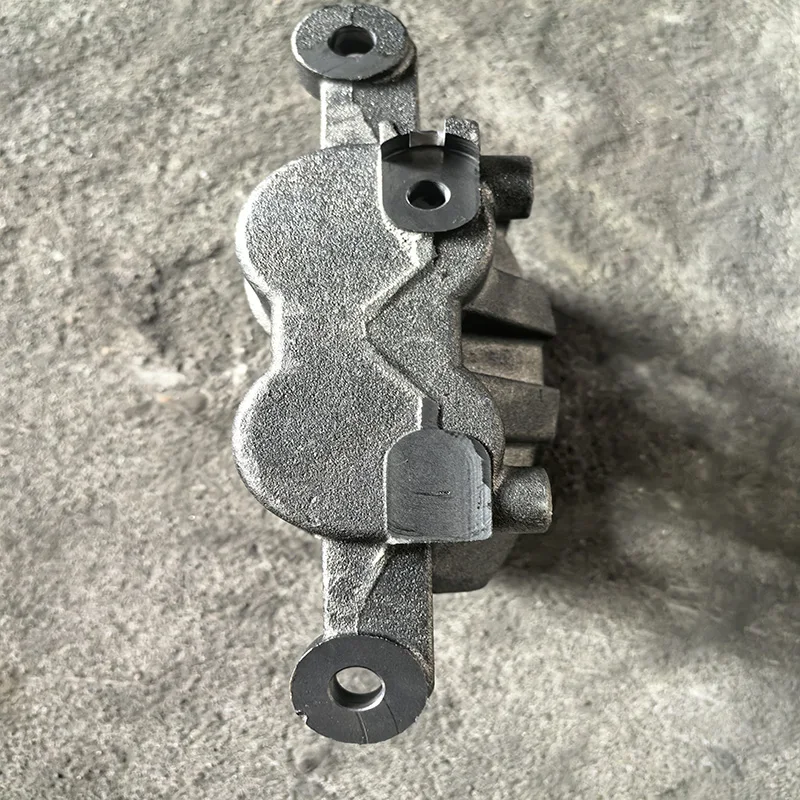

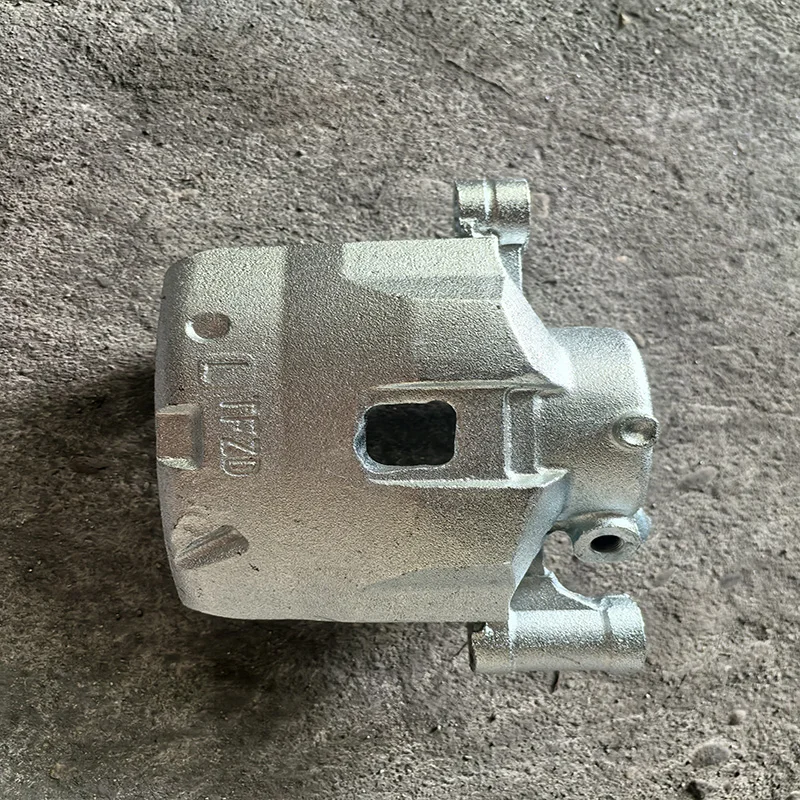

Aluminum alloy components manufactured through the combined processes of sand casting and CNC machining represent a sophisticated manufacturing solution that balances structural integrity, design flexibility, and cost-effectiveness. This integrated approach delivers precision components suitable for diverse industrial applications where complex geometries and reliable performance are paramount.

Material Excellence

Aluminum alloys utilized in sand casting applications are specifically formulated to provide optimal characteristics for both the casting and machining processes. These alloys, including A356, 356, and 319 aluminum, offer exceptional fluidity during pouring, which ensures complete mold filling and excellent reproduction of fine details. The material properties of these alloys provide an outstanding balance between mechanical strength and lightweight characteristics, making them ideal for applications where weight reduction is critical without compromising structural integrity.

Enhanced Performance Characteristics

Sand-cast aluminum components deliver exceptional mechanical properties including tensile strengths ranging from 30,000 to 45,000 psi, depending on specific alloy selection and heat treatment applications. The cast aluminum microstructure provides natural vibration damping capabilities superior to many wrought materials, while maintaining excellent corrosion resistance in various environmental conditions. Through specialized heat treatment processes including T5, T6, and T7 tempers, these components achieve enhanced strength, hardness, and dimensional stability tailored to specific application requirements.

Advanced Manufacturing Methodology

The sand casting process begins with creating a precise mold using bonded sand, which forms the negative impression of the desired component. This method accommodates complex geometries, internal passages, and varied wall thicknesses that would be challenging or cost-prohibitive with other manufacturing approaches. Following the casting process, components undergo precision CNC machining operations to achieve critical tolerances, refine mounting surfaces, and create precise bore geometries. This secondary machining ensures dimensional accuracy typically within ±0.005 inches (±0.127mm) for standard tolerances, with tighter tolerances available for critical features.

Comprehensive Application Versatility

The combination of sand casting and CNC machining produces components serving numerous industries:

Automotive and Transportation: Engine brackets, transmission cases, suspension components, and structural supports

Industrial Equipment: Pump housings, compressor parts, machinery bases, and gearbox cases

Aerospace and Defense: Avionics enclosures, support structures, and equipment mounting platforms

Energy Sector: Renewable energy components, generator parts, and power transmission elements

Marine Applications: Seawater-resistant components, deck hardware, and propulsion system elements

Quality Assurance and Economic Advantages

The sand casting process offers significant economic benefits for medium to high-volume production runs, with lower tooling costs compared to other casting methods. Combined with CNC machining's precision capabilities, this manufacturing approach delivers components with consistent quality verified through:

Dimensional inspection using advanced metrology equipment

Material certification confirming alloy composition and properties

Non-destructive testing including radiographic and liquid penetrant inspection

Pressure testing for components requiring fluid containment

This integrated manufacturing strategy provides OEMs with cost-effective solutions for producing durable, high-performance aluminum components with the precision necessary for demanding applications.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |