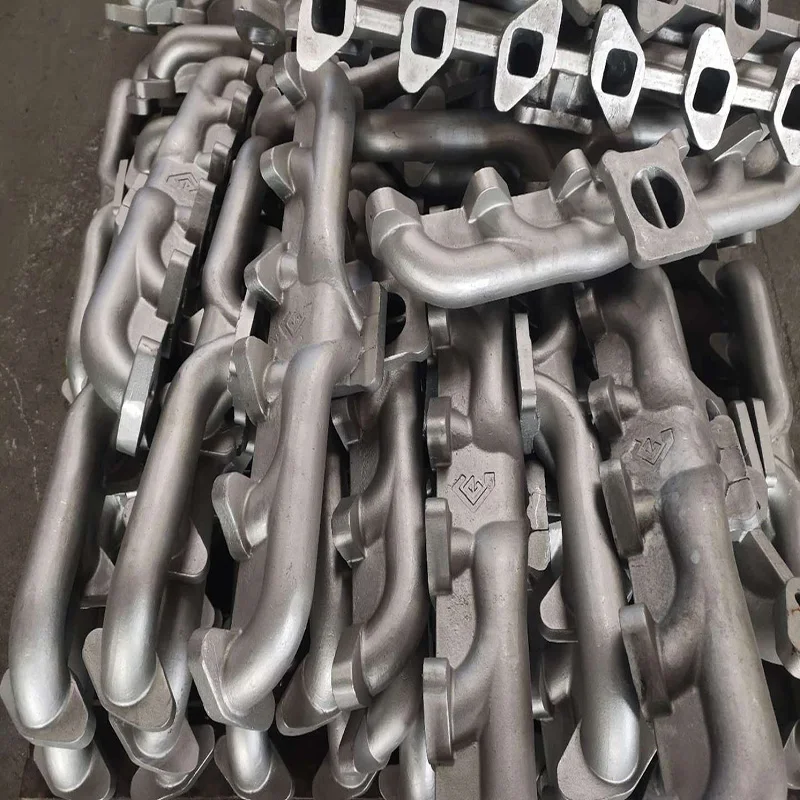

Stainless Steel Casting Stainless Steel Investment Casting Polished Parts Casting Steel Parts

- Overview

- Recommended Products

Stainless steel investment casting, also known as precision casting or lost-wax casting, represents one of the most versatile manufacturing processes for creating complex, high-quality metal components. This advanced manufacturing technique enables production of parts with exceptional dimensional accuracy, superior surface finish, and intricate geometries that would be challenging or impossible to achieve through conventional machining methods.

Material Selection and Properties

Investment casting supports various stainless steel grades, each offering distinct characteristics:

Austenitic Stainless Steels (304, 316, 304L, 316L):

These grades provide excellent corrosion resistance, good mechanical properties, and superior weldability. The low carbon variants (L-grades) offer enhanced resistance to intergranular corrosion, making them ideal for chemical processing and marine applications.

Martensitic Stainless Steels (420, 440C):

Known for their high strength and hardness capabilities, these steels are heat-treatable and commonly used for cutlery, surgical instruments, and mechanical components requiring wear resistance.

Precipitation-Hardening Grades (17-4PH):

Combining corrosion resistance with high strength, these alloys can be heat-treated to achieve tensile strengths exceeding 1000 MPa while maintaining good corrosion resistance.

Manufacturing Process Excellence

The investment casting process involves several meticulously controlled stages:

Pattern Creation: Precision wax patterns are injection-molded using aluminum dies designed with calculated shrinkage allowances.

Assembly: Wax patterns are assembled into clusters, forming the complete gating system for efficient metal flow.

Shell Building: Multiple ceramic coats are applied using advanced bonding technologies, creating a robust mold capable of withstanding extreme pouring temperatures.

Dewaxing: The ceramic shell is heated to remove wax, leaving a precise cavity for metal pouring.

Melting and Pouring: Stainless steel is melted in controlled atmosphere furnaces and poured at optimized temperatures to ensure proper fluidity and microstructure.

Finishing Operations: Castings undergo cutting, heat treatment, shot blasting, and precision machining to meet exact specifications.

Performance Advantages

Stainless steel investment castings deliver exceptional performance characteristics:

Dimensional Accuracy: Achieving tolerances of ±0.005 inches per inch

Surface Quality: Typical finishes of 125-250 microinches Ra, improvable to 32-63 Ra through polishing

Design Flexibility: Capable of producing complex internal passages, thin walls, and integrated features

Material Efficiency: Near-net-shape production minimizes material waste and secondary machining

Industry Applications

Aerospace and Defense: Turbine blades, engine components, structural brackets, and defense mechanisms requiring high strength-to-weight ratios and reliability.

Medical and Dental: Surgical instruments, implantable devices, dental prosthetics, and medical equipment demanding biocompatibility and sterilization capability.

Industrial Equipment: Pump housings, valve bodies, fluid handling components, and machinery parts requiring corrosion resistance and durability.

Food Processing: Sanitary fittings, processing components, and equipment parts needing polished surfaces and cleanability.

Automotive: Turbocharger housings, sensor components, and emission system parts withstanding high temperatures and corrosive environments.

Quality Assurance

Reputable investment casting manufacturers implement comprehensive quality management systems including:

Spectrochemical analysis for material verification

X-ray and fluorescent penetrant inspection

Mechanical property testing

Dimensional validation using CMM systems

Microstructure examination and corrosion testing

Conclusion

Stainless steel investment casting continues to evolve as a preferred manufacturing solution for critical components across diverse industries. The combination of material versatility, design freedom, and precision manufacturing makes this process invaluable for applications demanding high performance, reliability, and cost-effectiveness. As technology advances, investment casting capabilities expand, offering engineers increasingly sophisticated solutions for their most challenging component requirements.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |