- Overview

- Recommended Products

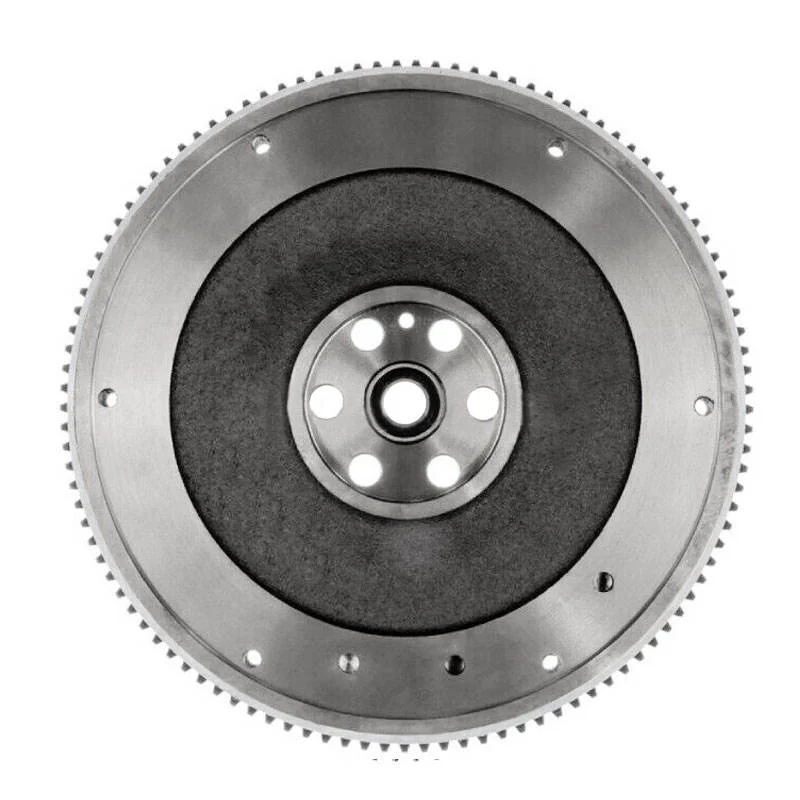

For performance enthusiasts, racers, and professional rebuilders, a worn or improperly surfaced flywheel can lead to clutch slippage, chatter, and premature failure. Our specialized service goes beyond simple resurfacing, offering a comprehensive package that includes precision machining, optional lightening, and dynamic balancing—all with labor included. This integrated service restores and enhances the performance and reliability of your steel flywheel, ensuring optimal power transfer and drivetrain smoothness.

Superior Material Integrity of Steel Flywheels

Our service is tailored for high-strength steel flywheels, typically crafted from forged or billet chromoly steel. This material is chosen for its exceptional tensile strength, impact resistance, and ability to withstand high-RPM stresses without risk of failure. Unlike cast iron, steel offers a superior strength-to-weight ratio, making it ideal for performance applications. We work to restore the pristine surface of this premium material, ensuring it can handle the aggressive engagement of high-performance clutch discs.

Precision Machining and Enhancement Processes

The core of our service is a precision resurfacing process performed on a state-of-the-art CNC lathe or flywheel grinder. This critical step removes minimal material to eliminate heat spots, cracks, and warping, creating a perfectly flat and parallel friction surface with the correct surface finish (RA value) for optimal clutch grip. We then offer an optional lightening service, where material is strategically removed from the flywheel's outer mass to reduce rotational inertia, resulting in significantly faster engine revving and improved throttle response. Finally, every flywheel undergoes dynamic balancing to eliminate vibrations that can cause harmful harmonics and damage crankshaft and transmission bearings.

Performance Application for Racing and High-Performance Use

This comprehensive service is essential for anyone involved in motorsports, from drag racing to road course competition, where engine response and drivetrain reliability are paramount. It is also the definitive solution for high-horsepower street builds and clutch replacement projects. A resurfaced, balanced, and optionally lightened flywheel ensures smooth clutch engagement, eliminates vibration, and protects the entire rotating assembly. By restoring the flywheel to optimal condition, we help maximize the efficiency and longevity of your clutch system, translating to more consistent and reliable performance on the track or street.

Trust our professional service to not just repair, but enhance your steel flywheel. We provide the precision and expertise needed to ensure your drivetrain operates at its peak.

Why are we called OEM experts in Exhaust Manifolds |

We develop over 100 different types of exhaust manifolds every year |

||||||

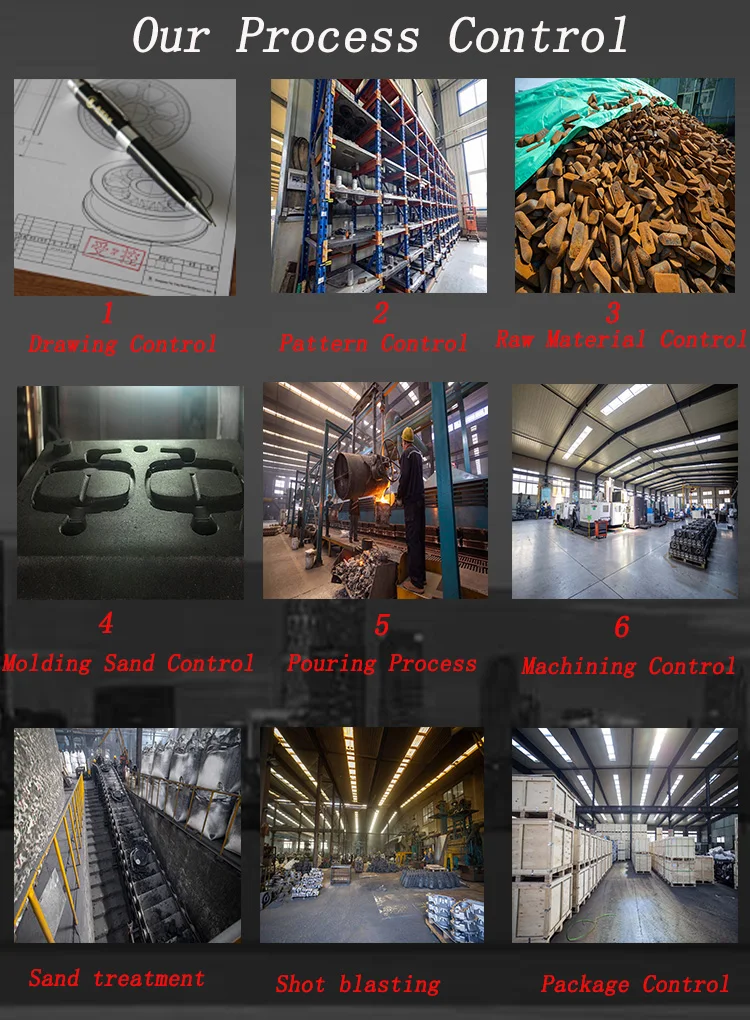

Dandong Pengxin Production Process for Exhaust Manifold |

Drawing Preparation: The Foundation of Precision,3D Scanning & Drafting: Our professional engineers use advanced scanners to convert samples into 2D/3D drawings (7–10 days). |

||||||

Pattern & Sample Development: Where Time Invested Pays Off |

Complexity: Exhaust manifolds often require 3–5 sets of metal patterns (vs. 1 set for simpler castings).Lead Time: 35–40 days for multi-cavity patterns; 25–30 days for simpler designs. |

||||||

Initial Orders & Batch Production: Scaling Responsibly |

Machine Allocation: One manifold order may occupy 2–3 molding machines. Our 16-machine facility prioritizes urgent orders and collaborates with partner foundries for auxiliary cores. |

||||||

How Investors Can Mitigate Delays |

Allocate 8–12 weeks for pattern/sample development. Compressing this risks quality failures. First batches take 20–30% longer due to process fine-tuning. Post-approval, lead times stabilize. |

||||||

Pre-sales

On Sale

After-Sales

results→Welcome to contact us for your customized solution.

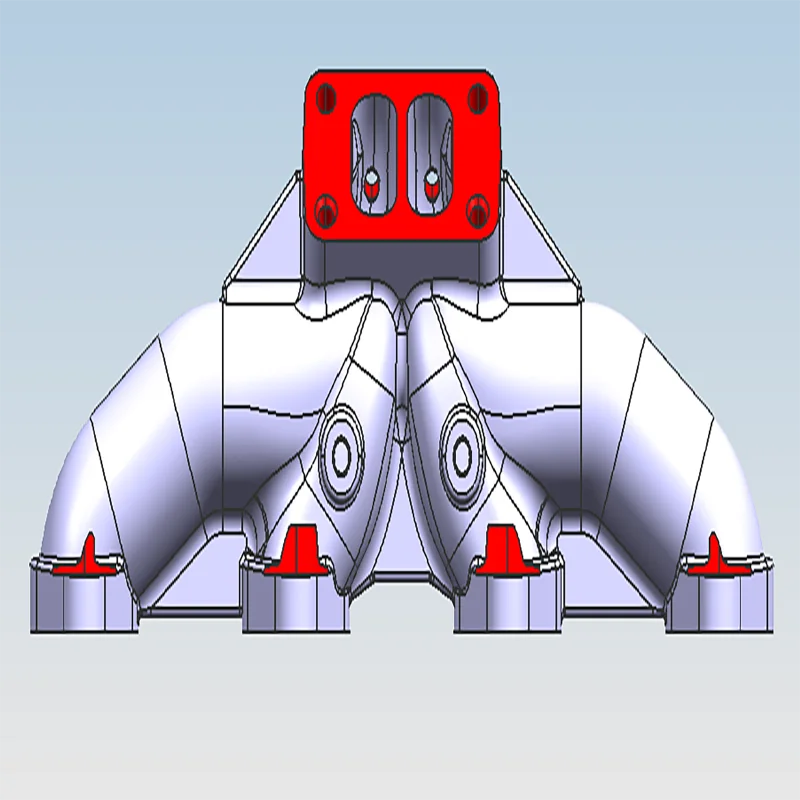

How did Dandong Pengxin Become a Top Manufacturer of Exhaust Manifold

Process designs derive from engineering drawings

3D scanners

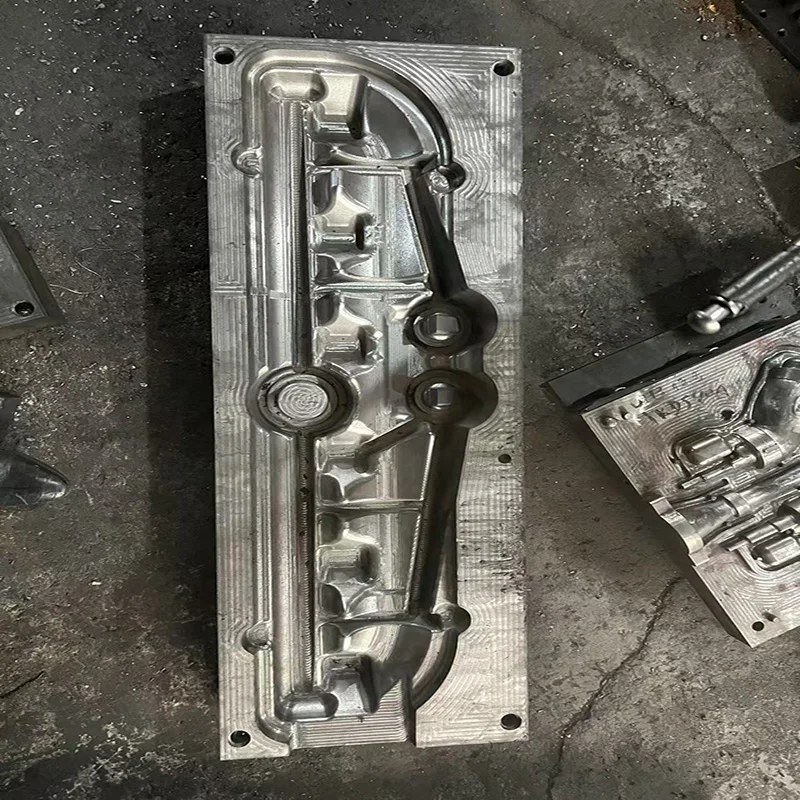

Metal Mold for Exhuast Manifold,Coated sand casting

Metal Mold for Exhaust Manifold,Sand Casting

Exhaust Manifold Core Box

Shell Molding Machine

Coated sand casting

Molding Machines

R&D

Production Capacity

Pattern Control

Abaqus,Moldflow and Moldex 3D, simulate feeding system, reduce casting defects and improve efficiency.

Raw Material Control

Machining Control