- Overview

- Recommended Products

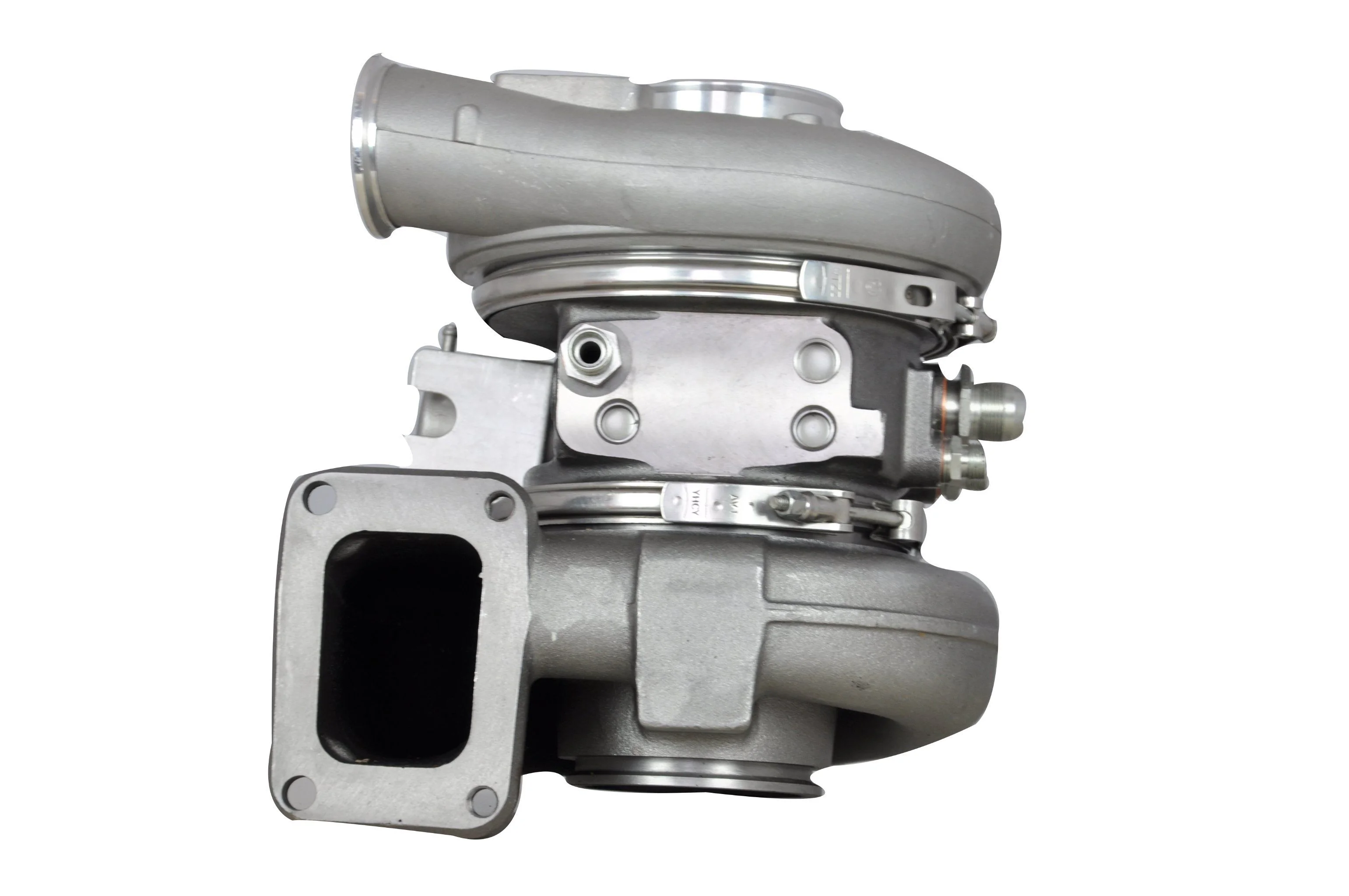

In the high-stakes world of automotive performance and efficiency, turbocharger systems are paramount. The manifold pipe, as the critical conduit channeling exhaust gases to drive the turbo, must withstand extreme conditions without failure. Our specialized OEM casting services are engineered to produce high-integrity turbocharger parts that meet the rigorous standards of the global automotive industry, delivering unmatched reliability in both mass production and specialized applications.

Advanced Materials for Extreme Environments

We select materials based on specific thermal and mechanical demands to ensure longevity under intense heat and pressure cycles. Our expertise includes:

Heat-Resistant Stainless Steels (e.g., SiMo Ductile Iron, AISI 304, 321, 316): Chosen for their excellent oxidation resistance and strength at elevated temperatures (up to 900°C+).

High-Nickel Alloys (e.g., Inconel 713C): Used for superalloy turbine housings in high-performance applications, offering exceptional creep resistance and durability.

High-Grade Aluminum Alloys (e.g., A380): For charge air coolers and intake components, providing an optimal strength-to-weight ratio and thermal conductivity.

Each alloy is meticulously controlled from melt to pour, with certification to meet OEM material specifications.

Precision-Oriented Production Process

Our manufacturing philosophy integrates advanced foundry techniques with precision machining to create components that perform reliably.

Shell Molding & Investment Casting: These are our primary processes for turbocharger components. They produce thin-walled, complex geometries with excellent surface finish and dimensional accuracy, essential for efficient gas flow and turbine response.

Sand Casting: Utilized for larger or more complex manifold structures, using resin-bonded sand for superior mold stability.

Critical Secondary Machining: Our CNC machining centers perform precision milling, drilling, and tapping of flanges, sensor ports, and wastegate interfaces, ensuring perfect sealing and assembly.

Value-Added Processing: We offer full heat treatment (solution annealing, aging), shot peening for stress relief, and non-destructive testing (dye penetrant, X-ray) to validate internal integrity.

Key Performance Characteristics

Exceptional Thermal Fatigue Resistance: Withstands repeated rapid heating and cooling cycles, preventing crack formation.

High-Temperature Strength & Creep Resistance: Maintains structural integrity and prevents deformation under continuous extreme heat.

Optimized Flow Characteristics: Smooth, as-cast surfaces and precise internal passages minimize exhaust backpressure, maximizing turbo spool efficiency.

Oxidation & Corrosion Resistance: Resists degradation from hot, corrosive exhaust gases.

Applications

Our cast turbocharger parts are integral to a wide range of vehicles, including:

Passenger Cars & Light Trucks: Exhaust manifolds, turbine housings, and outlet pipes.

Commercial & Heavy-Duty Vehicles: Durable manifolds and piping for diesel engines.

High-Performance & Racing Applications: Custom-designed, lightweight components for maximum power output.

As a trusted OEM partner, we deliver turbocharger castings that enhance engine performance, durability, and emissions compliance. Contact us to leverage our engineering expertise for your next project and receive a comprehensive solution from prototyping to mass production.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |